Pyrolysis Drives Sustainable Development

At Beston Group, we are committed to driving innovation and applying cutting-edge pyrolysis technology to address environmental

pollution and resource waste. We aim for:

Low-carbon Future

-

- Have removed 135,000 tons of CO2e

- Promote an emissions trading market

- Mitigate global warming and climate change

Circular Economy Model

- Have diverted 81,000 tons of waste from landfills

- Adopt cleaner syngas energy sources

- Reuse waste resources and reduce the consumption of new resources

Waste to Resource Pyrolysis Solution

Pyrolysis technology is the process of decomposing organic materials in high-temperature and oxygen-limited conditions.

Transform

At temperatures between 180℃- 400℃, waste plastic/oil

sludge/tire/rubber decompose into pyrolysis oil, carbon

black, and syngas.

Apply

- Pyrolysis oil:

- Industrial fuel

- Oil refinement materials

- Chemical raw material

- Carbon black:

- Reinforcing agent in tires

- Pigment for inks and

coatings

Transform

At temperatures between 380℃- 450℃, biomass decomposes in

a low-oxygen environment. They produce tons of valuable

biochar.

Apply

- Biochar:

- Industrial fuel/BBQ & Hookah charcoal

- Reducing agent in metal smelting

- Carbon sequestration

- Soil amendment

- Animal feed additive

- Building materials

Core Pyrolysis Technology Innovations

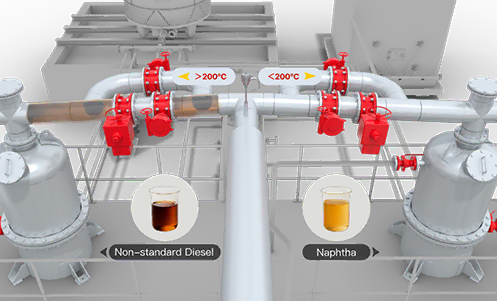

Fractional Distillation Technology

Integrates pyrolysis and distillation processes into a single machine, enabling the production of naphtha (below 200°C) and non-standard diesel (above 200°C) in one step.

- No need for extra distillation equipment, lowering occupied space and capital expenditure.

- Higher oil yield through reflux & heat integration.

30 Day Continuous Operation Technology

Advanced oil-gas anti-polymerization condensation design prevents olefin polymerization, which can clog oil-gas pipelines and machinery. Large-scale recycling capabilities:

- Tire Recycling: 10,000 tons annually

- Plastic Recycling: 6,000 tons annually

- Oil Sludge Recycling: 12,000 tons annually

Plastic Catalytic Dewaxing Technology

Uses granular molecular sieve catalysts for plastic catalytic pyrolysis, which prevent wax oil clogging in pipes and solve storage and transportation issues.

- Minimize machine downtime, boosting production efficiency by 200%.

- Increase pyrolysis oil yield and improve oil quality (meet ISCC PLUS standard).

Dual System Catalytic Pyrolysis Technology

Manifold + catalytic tower dual systems enable a single pyrolysis machine to simultaneously catalytically pyrolyze waxy plastic, waxy oil sludge, or pyrolyze common tires and oil sludge.

- Save customers from redundant investments.

- Improve pyrolysis unit utilization efficiency and enhance economic returns.

Continuous Biochar Pyrolysis Technology

Tar dust self-cleaning system ensures safe and stable operation for up to 720 hours.

- Suitable for large-scale project implementation.

- Comply with Puro.earth technical vetting standards.

- Bring carbon trading opportunities

Reactor Automatic Temperature Control Technology

Multi-fuel automatic combustion system + hot-air reuse system achieves precise ±10°C temperature control.

- Improve automation leveal, and reduce operational complexity

- More efficient combustion, better emission control, and easier environmental compliance

EU Standard Dedusting Technology

High-end flue gas dedusting technology that integrates cooling, denitration, desulfurization, and wet electrostatic precipitator processes enables EU emission standards. Some data as follows:

- SO: 50 mg/m³

- NOx: 200 mg/m³

- HF: 1 mg/m³

- HCl: 10 mg/m³

- Total dust: 1 mg/m³

Floating Seal Technology

Pyrolysis machine can achieve carbon fiber + high-temperature soft filler combined sealing in both feed inlet and slag outlet.

- Ensure stable dynamic sealing during continuous operation.

- Enhance high-temperature, corrosion, and wear resistance of Beston pyrolysis plant for sale.

Nitrogen Sealing Technology

Beston pyrolysis plant is equipped with a dedicated nitrogen system to ensure safe operation.

- Improves operational efficiency, reducing reactor cooling time by 4-5 hours.

- Nitrogen replaces the air inside the reactor, enabling safe operation and preventing flash explosion risks.

Awards & Achievements

Participation in Drafting “Solid Waste Pyrolysis

Treatment Standards” in China

2 Patented Designs of Continuous Pyrolysis Plant

Awarded by European Intellectual Property Office

44 Patents for Pyrolysis Equipment Design by China

National Intellectual Property Administration

Global Project Cases of Pyrolysis Plant

30 T/D Pyrolysis Plant in the Netherlands

- Raw Material: household waste plastics

- End Product Use: plastic pyrolysis oil as marine fuels and for distillatory refining

32 T/D Pyrolysis Machine in Africa

- Raw Material: local oil sludge

- End Product Use: as fuel or sales

10-15m³/h Pyrolysis Project in Europe

- Raw Material: waste straw

- End Product Use: straw biochar as boiler fuel

10-15m³/h Pyrolysis Project in Colombia

- Raw Material: rice husk with 13% moisture content

- End Product Use: rice husk biochar for soil improvement and as barbecue fuel

Service Support

![]()

Customize Solution

Professional project consultants design solutions according to your specific needs.

![]()

Pyrolysis Plant Manufacturing & Delivery

Strict quality control and fast delivery to ensure smooth project execution.

![]()

Project Implementation Support

Assist in obtaining project permits and offer relevant documentation support.

![]()

Install Guidance

On-site installation support from experienced engineers for smooth setup to pyrolysis machine.

![]()

Operational Training

Comprehensive personnel training and joint operation services are available to enhance your team’s capabilities.

![]()

After-Sales Support

Ongoing technical support and future upgrades for your pyrolysis plant.