1. Project Background & Challenges

The South African customer operates in the smelting industry and faces two main challenges:

- A large amount of non-recyclable plastic and tyres accumulates at the factory.

- High fuel costs in smelting negatively impact efficiency and profitability, requiring a more cost-effective alternative.

2. Goals for Change

To address these challenges, the client aims to achieve the following objectives through the pyrolysis project:

- Effectively recycle waste plastic and tyres to reduce the accumulated volume.

- Produce alternative fuel oil to lower the high fuel consumption costs in the smelting process.

- Solve the plastic wax oil issue and ensure smooth production.

3. Solution and Actions

The South African customer chose Beston Group’s pyrolysis and distillation solution, which includes:

- 2 sets of BLJ-16 Pyrolysis Equipment: The tire/plastic pyrolysis plant features a dual-system setup of “Manifold + Catalytic Tower”, controlled by valves for flexible processing. During plastic pyrolysis, the oil gas passes through the catalytic tower, effectively preventing the formation of wax oil. For tyre pyrolysis, the oil gas flows through the manifold for regular pyrolysis.

- BZJ-10 Distillation Equipment: Further distill the pyrolysis oil, refining it into high-purity fuel oil with better combustion performance. The refined fuel will be used in smelting furnace and old trucks.

4. Project Outcomes

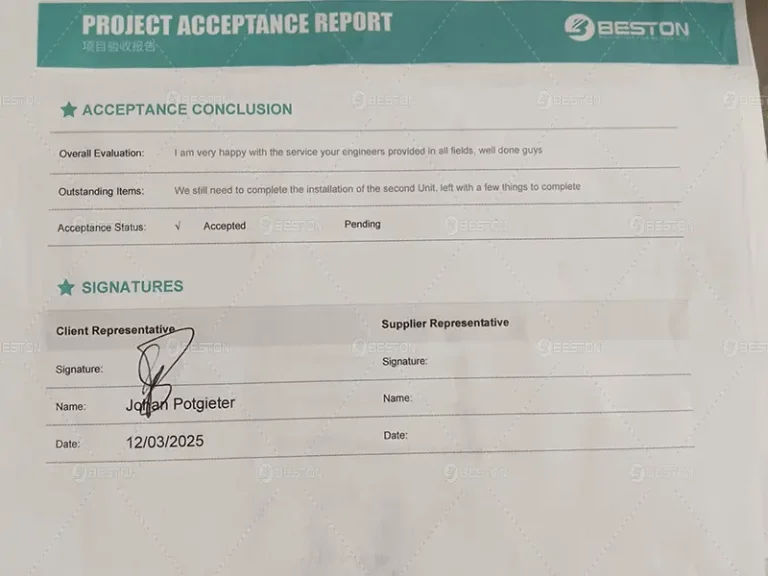

The project placed an equipment order on June 7, 2023, began machine operations on February 26, 2025, and successfully passed acceptance on March 12, 2025. The project will continue to deliver the following key results:

- Waste Reduction: Recycling 3,000 tons of plastic waste and 4,000 tons of scrap tires annually.

- Cost Reduction & Efficiency Improvement: The use of pyrolysis fuel oil replaces expensive smelting fuels, boosting the smelting plant’s profitability.