Continuous pyrolysis plant can process up to 6,000 tons of waste plastics, 10,000 tons of waste tires, or 12,000 tons of oil sludge annually. With high automation, it enables 30 days of non-stop operation. Its energy-efficient and eco-friendly features further enhance its appeal. These make it an increasingly popular choice among investors. Read on to explore this large-scale pyrolysis solution in greater detail.

Continuous Pyrolysis Plant: 3 Materials Recycling Made Easy

Plastic Waste

- Acceptable Feedstock: PE, PP, PS, ABS, etc. (refuse PET, PVC)

- End Products and Yield: Pyrolysis oil (40%-95%), syngas, solid residues

- Technology: catalytic pyrolysis

- Annual Processing Capacity: 6,000 tons

Oil Sludge

- Acceptable Feedstock: oil-contaminated soil (a kind of oil sludge)

- End Products and Yield: pyrolysis oil, sand, water, syngas

- Technology: common pyrolysis or catalytic pyrolysis

- Annual Processing Capacity: 12,000 tons

Waste Tire

- Acceptable Feedstock: various tires

- End Products and Yields: pyrolysis oil (35-45%), carbon black (30-35%), steel wire (8-15%), syngas (8-15%)

- Technology: common pyrolysis

- Annual Processing Capacity: 10,000 tons

Applications of Valuable Pyrolysis Products

Pyrolysis Oil

- Industrial Fuel: With high calorific value, pyrolysis oil serves as a cost-effective alternative to fossil fuels in energy-intensive industries.

- Advanced Fuel Refinement: Distilling pyrolysis oil can get naphtha. Refineries can reprocess naphtha into standard gasoline and diesel.

- Plastic Manufacturing: Pyrolysis oil from continuous plastic pyrolysis plant can be reused to produce new plastic products, supporting a circular economy.

Recovered Carbon Black (rCB)

- Tire Manufacturing: It can be reintegrated into the tire production process, either partially replacing virgin carbon black or as a performance-enhancing filler, contributing to sustainable tire development.

- Industrial Materials: rCB from continuous tyre pyrolysis plant can be used in the production of cement, asphalt inks, coatings, and various industrial composites.

Technology Upgrades in Continuous Pyrolysis Plant

Oil Gas Anti-polymerization Condensation Technology

This technology rapidly reduces oil-gas temperatures, effectively preventing olefin polymerization and pipeline blockages.

Key data highlights:

- 0 pipe blockages

- 30-day continuous operation

Hot Flue Gas Recirculation + Air Preheating Technology

This technology 100% fully recycles the heat energy from waste flue gas. This reduces related operating cost.

Key data highlights:

- 55% energy-saving than before

- 50% emission reduction than before

Reactor Automatic Temperature Control Technology

The continuous pyrolysis reactor automatically adjusts the fuel mix ratio. This improves the machine’s automation level.

Key data highlights:

- ±10℃ precise temperature control

- Only 2 Operators Required

Parameters of Continuous Pyrolysis Plant for Sale

| Model | BLL-30 |

|---|---|

| Manufacturer | BESTON |

| Time to Market | 2025 |

| Motor Brand | Chinese brand |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h |

| Working Method | Fully Continuous |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel |

| Reactor Life Span (Years) | 5-8 |

| Guarantee (Months) | 12 |

| Delivery Time (Calendar Days) | 60-90 |

| Land Space Required (L*W*H*m) | 70*20*10 |

| Packing | 20*6*3m in bulk+13*40HQ |

| Installation Period (Calendar Days) | 60-90 |

How Much Does A Continuous Pyrolysis Plant Cost?

Starting at $688,900, BLL-30 continuous pyrolysis equipment offers exceptional value to sustainable large-scale waste recycling. More than just equipment — you gain a complete solution backed by expert support. One-time investment, long-term profit!

Continuous and Batch Pyrolysis Plant: Key Configuration Differences

Fully continuous pyrolysis plant and batch type machine each have distinct configuration features. These differences make each system suitable for different operational goals and resource conditions. Below table for your quick reference.

| Difference | Continuous (BLL-30) | Batch (BLJ-16) |

|---|---|---|

| Capacity | 13–30 T/D | 12–16 T/D |

| Automation Level | High | Low |

| Heating Method | Hot air heating | Conduction heating |

| Feeding/Discharging | Continuous automatic feeding and discharging system | Batch feeding/discharging by manual labor or feeding machine |

| De-dusting Configuration | EU-standard dedusting system | Standard dedusting system |

| Condensation Configuration | Three-stage water cooling screw discharger; discharging without the need for cooling | Standard cooling system; wait for 7h reactor cooling before discharging |

| Working Shift | Each shift needs only 2 people | Each shift needs 3–5 people |

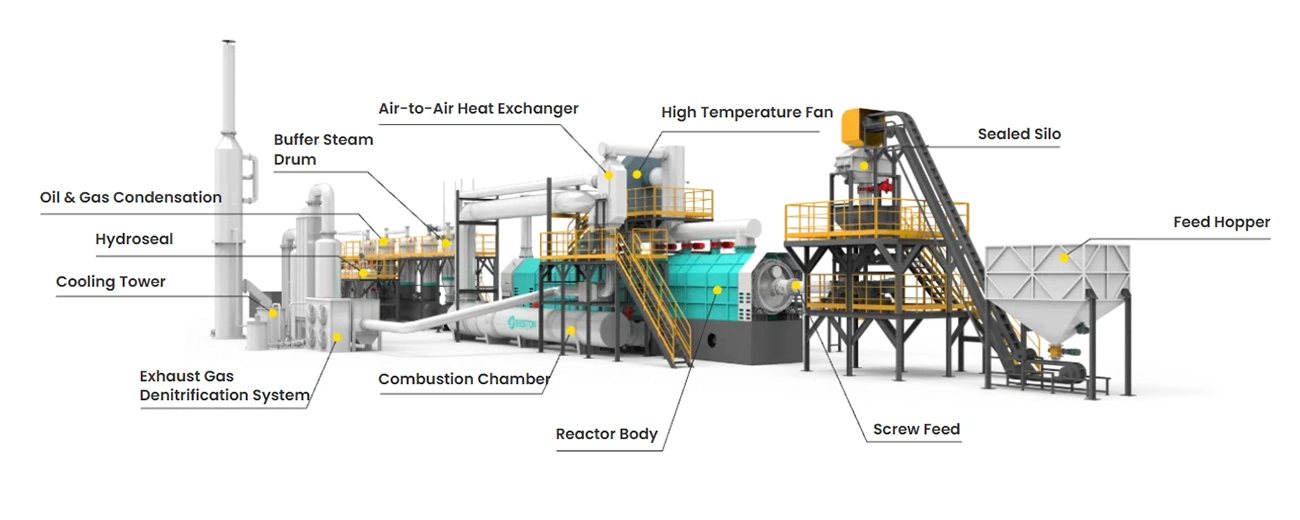

3D Display of BLL-30 Continuous Pyrolysis Machine

Focus on Continuous Pyrolysis Reactor: Excellence in Design

High-Temperature Resistant Materials

The reactor of continuous tyre pyrolysis plant is built with high-performance alloys that offer excellent heat resistance and corrosion resistance. This ensures long-term stability under high-temperature conditions. Options include:

- 310 Stainless Steel – Up to 1035°C resistance.

- 304 Stainless Steel – Up to 600-700°C resistance.

- Custom Materials – Tailored to specific customer requirements.

Anti-Coking Designs

Material coking on the reactor wall leads to poor heat transfer, unstable reactions, and higher energy consumption and maintenance. Beston Group addresses this issue through various measures.

- Internal Mechanical Chain De-coking Structure: Utilizes continuous friction in the rotary reactor to effectively prevent material coking.

- Hot Air Heating Method: Minimize the temperature difference between the inside and outside of the reactor to suppress coking.

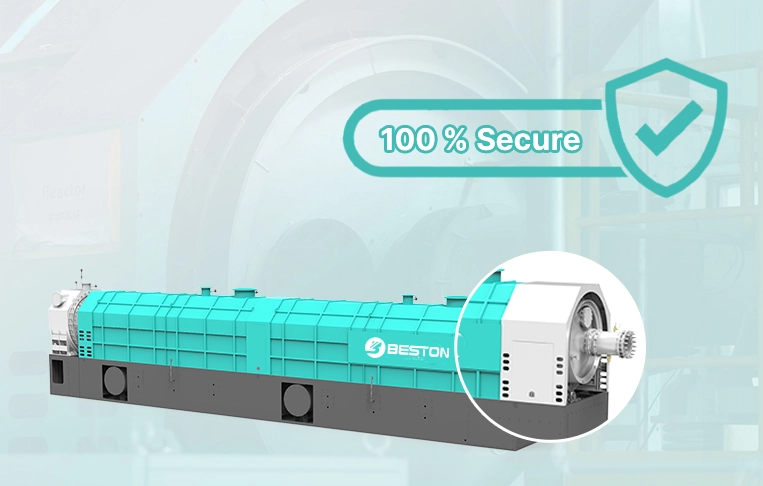

Secure Sealing Structure

At the feeding and discharging ports, BLL-30 continuous pyrolysis reactor adopts high-carbon fiber sealing rings + high-temperature-resistant flexible packing. This design provides the following advantages:

- Safety: Prevents oxygen from entering the reactor, reducing explosion risk; prevents leakage of high-temperature oil-gas.

- Ease of Operation: The flexible packing structure is easy to install and maintain, minimizing downtime losses.

Smarter & Safer: Technologies Behind Continuous Pyrolysis Plant

Percise Feeding – Smarter

- Automatic Screw Conveying: Achieve efficient and stable material transfer; improve overall productivity.

- Gram-Level Weighing Control: High-precision electronic scales enable gram-accurate feeding, real-time monitoring, and phased data tracking.

Integrated Control Technology – Smarter

- PLC and DCS Remote Control System: Improve automation efficiency; ensure stable equipment operation; effectively reduce labor costs; improve the working environment.

- Internet of Things (IoT) System: Enable real-time monitoring for continuous pyrolysis machine, empowering clients with efficient and centralized operational control.

Nitrogen Protection Technology – Safer

The feeding system utilizes nitrogen with a purity of over 95% to displace the air inside the sealing material bin. This maintains an oxygen-deficient environment inside the continuous pyrolysis reactor. It ensures the smooth progress of the pyrolysis reaction.

Discharging Sealing Technology – Safer

The discharge system uses a water-cooled sealed slag tank equipped with high and low level sensors. By controlling the material level to form a seal, it ensures that high-temperature oil vapors do not leak during continuous slag discharge and prevents air from backflowing into the main furnace.

How Does A Continuous Pyrolysis Plant Work?

01 Feeding

Take screw feeding as an example,

- The first screw feeder conveys raw materials in a silo for precise weighing.

- The second screw feeder then delivers the accurately quantitative material into the continuous pyrolysis reactor.

| Raw Materials | Feeding Way | Feeding Size |

|---|---|---|

| Waste Plastic | Shafted Screw Conveyor | Less than 2 cm |

| Waste Tyre | Shafted Screw Conveyor | Less than 15 mm |

| Oil Sludge (40%–60% liquid content) | Shaftless Screw Conveyor | / |

| Oil Sludge (more than 75% liquid content) | Oil Slurry Pump | / |

02 Pyrolysis

In the controlled oxygen-free reactor, materials decompose instead of burning when exposed to high temperatures..

- When the temperature reaches 180℃, oil gas begins to generate.

- When the temperature is between 280-350℃, a large significant amount of oil gas appears.

03 Oil Gas Condensation

The light oil gas will be liquefied into fuel oil by the condenser and stored in the fuel oil tank.

04 Syngas Recycling

05 High Temperature Flue Gas Reuse

- Guide 80% of hot flue gas from the reactor back into the combustion chamber. Mix it with 1000-1300℃ hot air from combustor. Use the mixture to heat the reactor.

- Use the remaining 20% of hot flue gas to heat fresh combustion air. Thus the hot combustion air can offer an oxygen condition for combustor.

06 Solid Residue Discharge

07 Exhaust Gas Treatment

Pyrolysis Project All Over the World

Future Trend: Global Transition to Continuous Pyrolysis

Comply with Stricter Global Emission Standards

With stricter regulations like the EU Industrial Emissions Directive (2.0), global oversight of industrial emissions is tightening. Continuous pyrolysis machine offers more stable reactions, cleaner operations, and easier emission compliance. This helps companies build greener factories and stay aligned with long-term policy trends.

Meet Growing Demand for Solid Waste Treatment

Accelerating urbanization is driving a steady rise in solid waste, such as waste plastic, tires, etc. Continuous pyrolysis equipment, with 30-day non-stop operation and high automation, is ideal for large-scale processing. It helps cities advance waste reduction and resource recovery goals.

Meet Market Demand for High-Quality Pyrolysis Oil

As the energy transition and circular economy progress, demand for high-quality pyrolysis oil is rising across refining, chemical, and energy sectors. Continuous tyre pyrolysis plant offers precise control over temperature and reaction time, ensuring consistent, large-scale production of high-quality oil.

Align with Low-Risk & High-Return Investment Strategy

With strong environmental benefits, continuous pyrolysis projects facilitate project approval and qualify for subsidies. The pyrolysis outputs enjoy strong market demand and high economic value. Thus, the project offers promising returns with manageable risks, increasingly becoming attractive to capital investment.

Complete Support to Launch Your Continuous Pyrolysis Project

Choosing Beston Group means more than just choosing continuous pyrolysis plant — it means choosing a one-stop solution. We understand that successful project implementation involves comprehensive coordination and compliance across multiple aspects. Therefore, we offer full-spectrum support to help you navigate project challenges with ease:

Environmental Impact Assessment (EIA) Support

- Offer technical documentation required for EIA, like emissions data and corresponding control solutions.

- Assist clients in liaising with third-party EIA agencies to reduce communication costs.

- Ensure compliance with environmental regulations across regions (e.g., EU standards, EPA regulations).

Safety Assessment (SA) Support

- Provide technical documentation required for safety assessment procedures.

- Guide enterprises in implementing effective safety management measures.

- Support clients in completing relevant safety inspections and acceptance processes.

Additional Implementation Support

- Site planning and layout recommendations

- Installation, commissioning, and operational training

- Consultation support for certification or qualification applications

- Other after-sales service and remote technical support

Get Continuous Pyrolysis Solution Now

Take the first step toward efficient recycling today! Beston Group’s continuous pyrolysis plant helps you turn waste into valuable resources while supporting your sustainability goals. Contact us now for customized solutions and expert support. Follow us on YouTube/Facebook/Linkedin/Pinterest for regular updates.