Biochar production equipment uses pyrolysis (heating biomass without oxygen) to convert biomass into biochar, ranging from small kilns/drums to large industrial systems. All are designed for different scales and processing organic waste like wood, coconut shells or agricultural residue into soil enhancers and carbon sinks. For industrial-scale solutions, explore Beston Group’s biochar machine offerings.

Classification of Market-Available Biochar Production Equipment

Biochar production equipment encompasses a range of thermochemical processes, configurations and scales to meet diverse operational needs. Common classsfication as follows:

By Deployment Location

- Mobile Facility: Transportable system for biochar production in multiple locations. Mobile assets are by construction smaller, and often grouped in fleets.

- Stationary (Fixed) Facility: Biochar prodution at a fixed location.

By Production Scale

- Small-scale Artisanal Kilns: Ideal for farms, gardens, educational use, and pilot projects.

- Industrial-scale Plants: Highly automated, continuous systems designed for high-volume commercial production.

By Core Technology

- Pyrolysis: The most prevalent method, heating biomass in the absence of oxygen.

- Torrefaction: Mild pyrolysis at lower temperatures.

- Hydrothermal Carbonization: Uses heated, pressurized water to convert wet biomass.

Beston Group offers stationary, industrial-scale biochar machine based on pyrolysis technology.

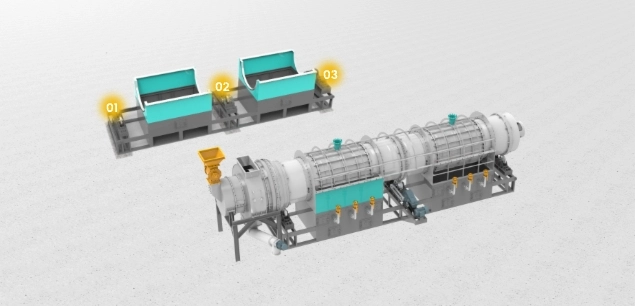

How Pyrolysis Turns Biomass into Biochar? – Biochar Machine Workflow

Step 1 – Biomass Prements & Feeding

- Dry and crush biomass to feeding requirements: Moisture Content < 15% | 5mm< Particle Size < 20mm

- Load biomass waste to the silo. Then screw belt conveyor transports bioamss into the inner cylinder of the biomass pyrolysis reactor.

Step 2 – Biomass Pyrolysis into Biochar

- In the inner cylinder (medium-temperature zone), biomass materials undergo drying and semi-carbonization.

- Then the screw pushes them to drop into the outer cylinder (high-temperature zone) for complete pyrolysis, producing biochar.

Step 3 – Syngas & Flue Gas Recycling

- Syngas Recycling: Syngas generated during the pyrolysis process is purified and then used as the heat source for the reactor.

- Flue Gas Thermal Energy Utilization: Flue gas heat is partially used for dryer heating and partially for pipeline insulation to prevent tar and wood vinegar condensation and biochar equipment blockage.

Step 4 – Biochar Discharging

Discharge biochar through the water-cooling discharging system. Normally, the final biochar temperature is ≤45°C.

Step 5 – Exhaust Gas Treatment

After the heat energy is recovered, the final flue gas undergoes multiple dedusting treatment. The emissions meet EU environment standards.

Recyclable Biomass to Make Biochar – Types/Requirements

Common Biomass Types to Make Biochar

- Agricultural Waste: Rice husk, straws, sugarcane bagasse, jute stalks.

- Forestry Waste: Wood chips, sawdust, wood shavings, bamboo waste, eucalyptus bark.

- Food Processing Waste: Coconut shells, palm kernel shells, peanut shells, almond shells, hazelnut shells, olive husks, and coffee grounds.

- etc.

Standard to Choose Biomass Material Types

- Good flowability: Poor flowability can cause materials to stop flowing and accumulate in the hopper (e.g., palm fibers have poor flowability).

- Uniform size: Oversized materials can jam the feed screw, while overly thin materials tend to turn into powder.

- Low dust/powder: Excessive powder in raw materials can clog pipelines and affect biochar quality. (Harder materials, such as coconut or fruit shells, are recommended.)

Get Biochar to Apply

Carbon Removal – The Fastest-Growing Application of Biochar

Biochar Carbon Removal (BCR)

Plants capture CO₂ from the atmosphere via photosynthesis. Biochar transforms this carbon into a highly stable form that can persist underground for centuries. Thus, BCR become an effective solution for climate change mitigation.

| Indicator | 2022 | 2023 | 2024 | 2025 (H1) |

|---|---|---|---|---|

| Contracted BCR volume (Mt) | — | — | — | 1.6 Mt |

| Cumulative BCR volume (Mt) | — | — | — | ≈3.04 Mt |

| Market value (USD) | $14.6M | $33.9M | $181.5M | — |

Note: Table 1 data sourced from CDR.fyi. Undisclosed data marked “—”.

| Top Buyer | Representative Purchase |

|---|---|

| Microsoft | 1.24 Mt biochar CDR offtake (Q2 2025, Exomad Green) |

| ~100,000 t biochar-related CDR agreement (India) | |

| Boston Consulting Group | 50,000+ t durable CDR purchases (incl. biochar) |

Other Application of Biochar

Soil Improvement: Sustainable Agriculture

- Enhances soil aeration and drainage, and promotes nutrient cycling

- Adsorb harmful substances in the soil, remediating polluted soils.

- Neutralize acidic soils

Building Materials Additive: Decarbonization Construction Industry

Biochar can be used as an additive in concrete, asphalt, and bricks. Benefits include:

- Helps improve insulation and enhances durability

- Locks carbon into buildings for long-term carbon sequestration

Metal Smelting Reducing Agent

- Replace traditional fossil fuel reducers (such as coal and coke) and significantly reduce carbon emissions as well as harmful gases like sulfur oxides.

- Reduce the cost of raw materials for metal smelting.

Feed Additive: Low-Carbon Animal Husbandry

- Reduce ruminant methane emissions. (Note: Ruminant-derived methane accounts for 30% of global anthropogenic methane emissions.)

- Reduces harmful substances in feed like pathogens, improving overall animal health.

Industrial Fuel

- Provide renewable energy solutions and promote the transformation of the energy structure.

- Reduce reliance on fossil fuels and decrease pollution.

Parameters of Biochar Production Equipment for Sale

BST-50S Model

- Suitable for enterprises familiar with carbon sinks aiming for large-scale production and maximized profits.

- Suitable for enterprises aiming to strengthen brand image through green biochar carbon removal.

BST-06 Model

- Ideal for testing carbon sink feasibility with low cost and low risk.

- Help investors understand the carbon sink trading model.

- Suitable for start-up enterprises, projects with demonstration or educational purposes, etc.

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

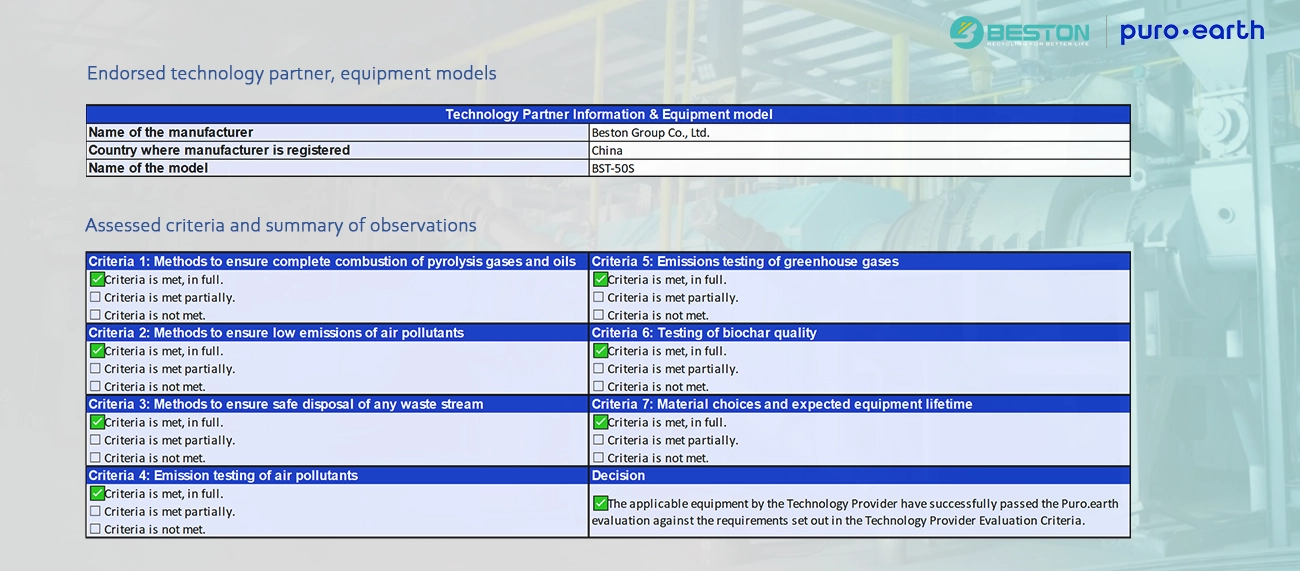

Beston Biochar Pyrolysis Technology Meeting Puro.earth Standard

Beston BST-50S biochar production equipment passed Puro.earth evaluation, meeting 7 Key Criteria. This accelerates the certification process for carbon removal projects, helping investors get carbon credits faster.

| Load capacity | EBC Standard | German Laboratory | Chinese Laboratory |

|---|---|---|---|

| H/C Molar Ratio | <0.4 – 0.7 | 0.45 (Generally Meets All Application Standards) | 0.11 – 0.32 |

| Heavy Metal | Depends on Specific Application | Fully Meet All | Fully Meet All |

| PAHS-8 | Depends on Specific Application | Fully Meet All | / |

| PAHS-16 | <6 mg/kg | Compliant with EBC-Feed, Urban, Basic Material Slightly above EBC Feed-Plus, Agro-Bio, Agro | 0.2 mg/kg |

- Meet GHG Emission Standards: CH₄ emissions < 0.1% of the carbon stored in the biochar; N₂O emissions < 1% of the carbon stored in the biochar

- Meet Air Pollutants Emission Standards: Equipped with an advanced exhaust treatment system, the tested machine meets stringent environmental standards.

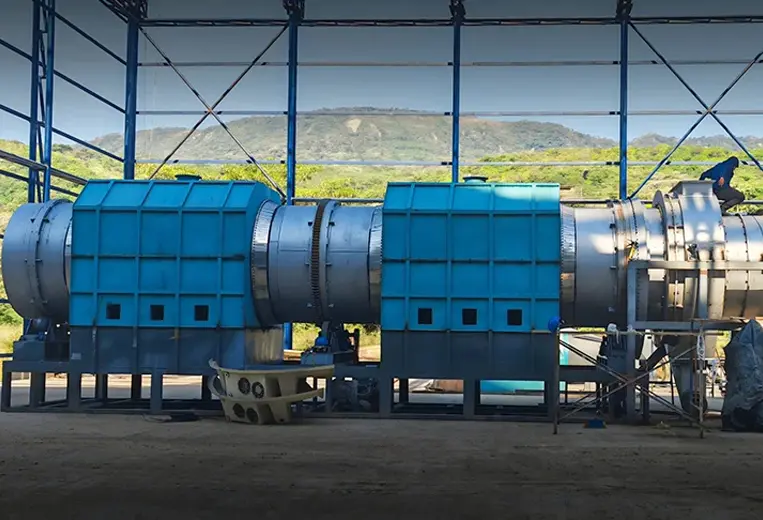

Industrial-Scale Biochar Carbon Removal Project in Spain

Euthenia Energy is expanding into biochar carbon removal using industrial-scale equipment supplied by Beston Group. This is backed by over 25 years of experience from its parent company Euthenia Capital in carbon management, renewable energy, and waste treatment projects. The partnership offers a commercial reference for biochar-based CDR projects in Europe.

Project Information

- Customer: Euthenia Energy

- Project Location: Spain

- Project Timeline: Jan 2023 Launch | Mar 2024 Start Operation

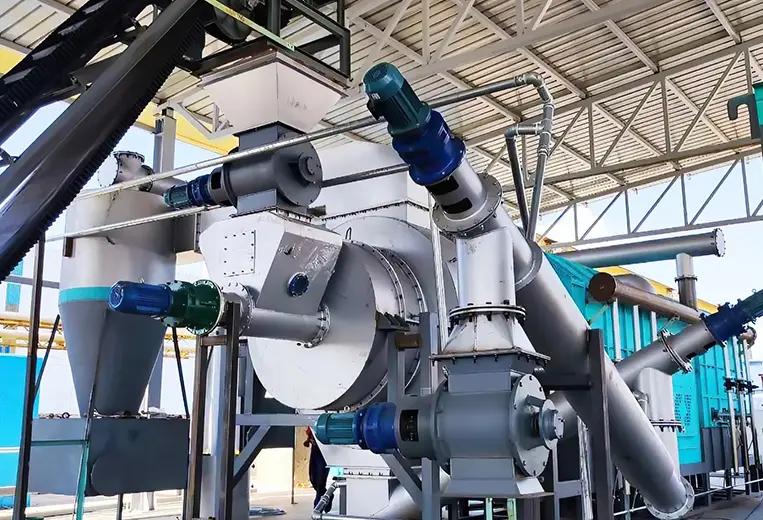

- Project Configuration: BST-50 industrial biochar machine + dryer + crusher

- Annual Output: 6,000 tons of biochar

- CO₂ Sequestration Potential: ~12,000 tons/year

- Application: Biochar-based carbon removal and carbon credit generation

Project Status

Current Status:

- Installed, commissioned, and in stable operation

- Site visits are available upon request for qualified industry professionals.

Industry Recognition | On-site Technical Exchange

In November 2025, the project site hosted the 2025 European Biochar CDR Conference. Experts studied and verified its operational stability and engineering reliability through an on-site visit, confirming its practical feasibility for commercial, industrial-scale CDR applications.

Video Review of 2025 European Biochar CDR Conference

CDR Project Success Guide: Beston Group’s Full Lifecycle Support

Launching a compliant, verifiable CDR project that generates expected carbon credits faces three core challenges:

Beston’s biochar solutions provide systematic support for these challenges.

1. Technology Compliant with Puro.earth CDR Standards

The BST-50S model become Puro.earth Authentication Model. Biochar production strictly adhere to international CDR methodology requirements.

- Key Benefit: Accelerate the carbon credit certification process.

2. Integrated dMRV Supports CDR Project LCA Accounting

What is dMRV?: The dMRV (Dynamic Monitoring, Reporting, and Verification) system is a technological tool used for real-time monitoring and reporting of carbon emission reduction project data, ensuring that all data complies with international verification standards.

What is LCA?: LCA (Life Cycle Assessment) evaluates the environmental impacts of a project throughout its entire lifecycle, from raw material extraction to final disposal.

Beston’s biochar production equipment can be integrated with dMRV systems and APIs for real-time lifecycle data reporting. We have strategic partnerships with leading dMRV suppliers and can assist with connections to meet your project needs.

- Key Benefit: Guarantees the reliability and transparency of carbon removal data for third-party verification.

3. Full Lifecycle Technical Support

Covering all stages from initial project feasibility analysis, mid-term technology deployment and operation and maintenance, to post-project third-party verification assistance.

- Key Benefit Effectively reduces project risks and ensures long-term stable operation and return on investment.

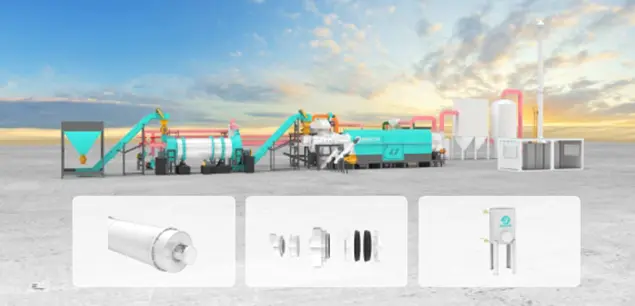

Technical Advantages of Beston Biochar Production Equipment

Tar & Wood Vinegar Self-Cleaning System – 720h Continuous Operation

The system prevents blockages caused by tar, wood vinegar, and other substances, ensure 7200 hours stable operation annually. Benefits:

- Reduce downtime and maintenance and related economic loss.

- Better meet environmental compliance.

- Enhance safety by lowering the risk of fire and dust explosions.

Energy-efficient Designs

- Dual-cylinder + Rotary Reactor: Fully carbonizes biomass, improves thermal efficiency and achieve over 10 m³/h processing capacity.

- Syngas Recycling Technology: Achieves self-sustaining energy utilization, saving fuel consumption and cost by 20%.

Eco-friendly Guarantee Designs

- Multi-stage Cyclone Dedusting: Ensures a clean operation site via dedusting at the dryer, feed port, and connecting pipes.

- High-end Exhaust Gas Treatment: Multi-stage treatments ensures compliance with strict EU emission standards.

Durable Reactor Structure Designs

- 310s Stainless Steel Reactor Material: Offers high resistance to heat and corrosion and ensures reliable performance of biochar machine.

- Three-point Support Design: Evenly distributes the load and pressure, reducing machine wear or tilting for greater durability.

Multiple Safety Guarantee Designs

- Dynamic Sealing Design: The equipment’s inlet and outlet are sealed using a combination of materials, ensures reliable dynamic airtightness during operation.

- Two-way Explosion-proof System: The explosion-proof hole and explosion-proof water seal prevent equipment damage or safety accidents.

More Biochar Projects Practices: Various Biomass Recycling

Rice Husk Recycling Project in Colombia

Project Goals

- Need a large-scale solution for recycling rice husk.

- Configure drying solution to counteract the impact of local rainy seasons.

Project Status

Installation Completed | Currently Operating

Project Outcomes

- The machine operates well even during rainy seasons, no worry about downtime loss caused by weather.

- Produce high-quality biochar that meets soil improvement standards, and can also be fuel.

Wheat Straw Recycling Project in Croatia

Project Goals

- Recycle large amounts of wheat straw, significantly reducing its volume.

- Produce biochar for use as an alternative fuel & soil improvement.

Project Status

Installation Completed | Currently Operating

Project Outcomes

- Reducing environmental impact and promoting circular agricultural practices.

Wood Chips Recycling Project in Finland

Project Goals

Utilize the abundant local wood resources to produce barbecue charcoal and generate profit.

Project Status

Installation Completed | Currently Operating

Project Outcomes

- Increase wood resource utilization, reduce environmental impact of waste, and foster the sustainability of the wood processing industry.

- Offer high-quality barbecue charcoal to the market, and earn profit through sales.

Biochar Yield and Specifications from Testing

Biochar Yield Analysis

Based on our testing with sawdust, rice husk, and crushed coconut shells, processing 1 ton biomass with moisture content below 10% can get 280kg-310kg biochar. The yield ratio stays stable at about 3:1 after the biomass moisture is removed.

Biochar Data for Different Biomass Types

| Item | Sawdust | Bamboo | Rice Husk | Coffee Shell | Coconut Shell | Cornstalk | Pecan Shell | Palm Silk Grain |

|---|---|---|---|---|---|---|---|---|

| Moisture (%) | 6.84 | 6.98 | 6.09 | 11.78 | 9.1 | 2.06 | 1.71 | 2.35 |

| Bound water (%) | 4.51 | 1.74 | 3.58 | 1.21 | 4.19 | 0.82 | 1.7 | 1.32 |

| Ash (%) | 5.871 | 16.62 | 39.08 | 2.75 | 0.18 | 35.14 | 4.42 | 7.91 |

| Volatile (%) | 20.8 | 18.2 | 19.12 | 30.96 | 6.95 | 25.18 | 7.03 | 9.32 |

| Fixed carbon (%) | 68.91 | 63.44 | 38.22 | 65.08 | 88.68 | 38.86 | 86.84 | 77.36 |

| Sulfur (%) | 0.08 | 0.02 | 0.12 | 0.02 | 0.09 | 0.03 | 0.02 | 0.08 |

| Max calorific value kcal/kg | 6454 | 5679 | 3860 | 7050 | 7277 | 4453 | 7484 | 5485 |

| Min calorific value kcal/kg | 6088 | 5171 | 3559 | 6053 | 6724 | 4199 | 7332 | 5265 |

Note: the analysis report is just for your reference. The detailed data ranges from different raw materials in different locations.

Huge Biochar Market Potential: Worth to Invest

The biochar market is rapidly growing, backed by carbon neutrality goals and strong global demand. While data estimates vary among research institutions, the consensus is clear—investing in biochar pyrolysis machine is a forward-thinking decision.

- From World Bank: Global carbon pricing and carbon market revenues have exceeded $100 billion.

- From McKinsey Management Consulting: By 2050, the carbon sink industry is projected to reach a market value of up to $1.2 trillion.

- From International Biochar Initiative: Biochar continues to lead in providing persistent carbon dioxide removal (CDR) credits in the voluntary carbon market (VCM), accounting for over 90% of global deliveries in 2023. Global biochar production is estimated to increase by at least 350,000 metric tons (mt) annually.

Looking Forward to Cooperating with You

Beston Group has been dedicated to manufacturing biochar production equipment for many years. We have always insisted on a customer-centric business philosophy and strived to provide customers with high-quality, efficient, and customized products and services. Our biochar machines exported all over the world have had a positive impact on fields such as renewable energy production, soil improvement, and carbon neutrality. We are looking forward to cooperating with more friends and opening a wider market! More dairly news in Linkedin!