1. Project Background & Challenge

The Indonesian customer is a coconut processing enterprise committed to sustainable production system. However, in the traditional hookah charcoal manufacturing process, they face several challenges, including:

- Unstable charcoal quality

- Low automation levels result in inefficient production and output that cannot meet market demand

2. Goals for Change

The customer aims to process coconut shells into high-quality commercial hookah charcoal. They seek to introduce a new production line capable of achieving highly automated, continuous, and stable production with a daily output of 25 tons.

3. Action and Solution

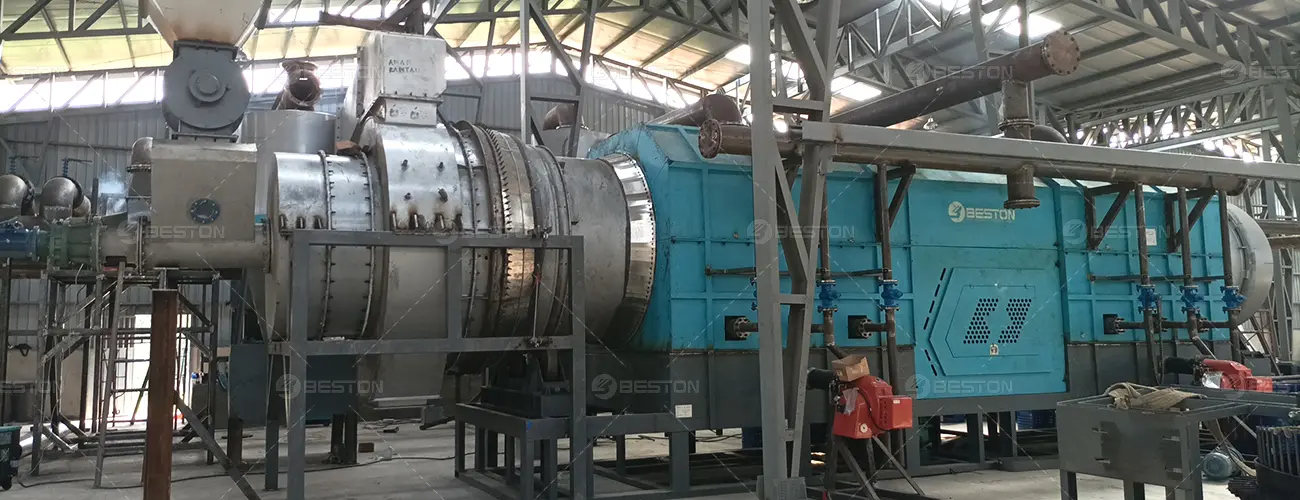

Beston Group offered the customer a complete solution for coconut shell carbonization and charcoal briquetting, systematically upgrading the processes of raw material pretreatment, carbonization, molding, and packaging. To learn more about the solution, please visit our coconut shell charcoal machine page.

- BST-50 Carbonization Machine: Achieves high-efficiency carbonization, ensuring stable charcoal quality.

- Model 2000 Dryer: Reduces the moisture content of coconut shells, improving carbonization efficiency.

- Crusher & Rotary Screen: Precisely crushes and screens coconut shells, providing efficient raw material preparation for carbonization.

- Hookah Charcoal Briquette Machine & Dryer: Compresses charcoal into dense, uniform briquettes; secondary drying to ensure high-quality hookah charcoal.

- Packaging System: Packages the finished hookah charcoal for convenient sale and transportation.

4. Project Outcomes

The entire project spanned 378 days, from the placement of the purchase order in July 2023 to successful acceptance and official operation in July 2024. The project is currently running smoothly, achieving biomass resource utilization, producing a large quantity of high-quality hookah charcoal, and significantly enhancing the client company’s market competitiveness.