As the volume of global solid waste continues to increase, thermal treatment technologies have attracted widespread attention due to their potential for waste reduction and energy recovery. Among these, pyrolysis and incineration are the two most representative methods. Although both processes use high temperatures to treat waste, they differ significantly in reaction conditions, types of by-products and environmental impacts. Read on to learn more details.

Basic Concepts of Pyrolysis and Incineration

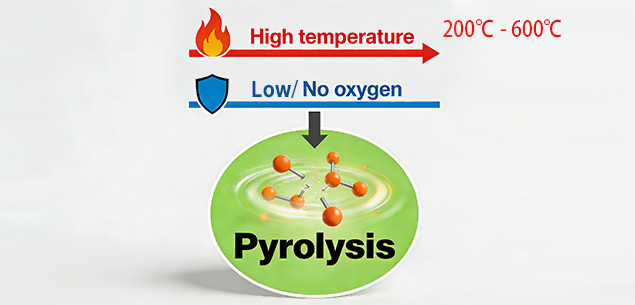

What Is Pyrolysis?

Pyrolysis is a technology in which organic materials are thermally decomposed under oxygen-limited conditions. The reaction temperature typically at 200°C to 600°C. Its final products include:

- Solid residues (biochar or carbon black).

- Liquid products (tar or pyrolysis oil);

- Combustible gases (contaning H₂, CO, CH₄, etc.);

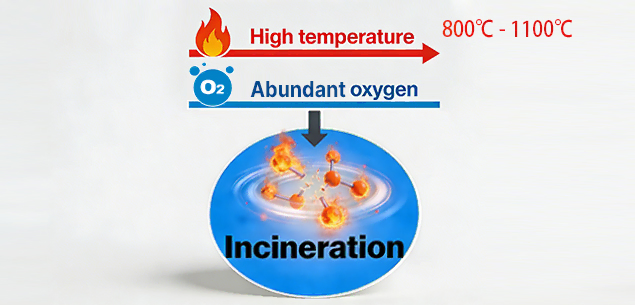

What Is Incineration?

Incineration is the process of complete combustion of the organic components of waste under sufficient oxygen conditions. The reaction temperature is typically above 850°C. Its final products include:

- Flue gas (containing carbon dioxide, water vapor, etc.);

- Ash residues;

- Released heat energy (used for power generation or heating).

Main Differences Between Pyrolysis and Incineration

Pyrolysis and incineration are both thermochemical conversion processes used for the treatment of organic waste materials. However, they differ significantly in reaction environment, reaction mechanism, and suitable waste types, as outlined below.

Reaction Environment

- Pyrolysis occurs at moderate or high temperatures (200–600°C) in the absence of oxygen.

- Incineration takes place at high temperatures (above 850°C) in the presence of sufficient oxygen.

Reactor Mechanism

- Pyrolysis is a non-combustion process that thermally decomposes organic materials into simpler compounds.

- Incineration is a complete combustion process where organic matter is fully oxidized, releasing energy in the form of heat.

Suitable Waste Types

- Pyrolysis is particularly effective for recycling tires, plastics, and biomass, as well as for the harmless treatment of oil sludge.

- Incineration is commonly used for municipal solid waste treatment, medical waste disposal, and hazardous waste treatment.

Products and Utilization

- Pyrolysis produces gas, liquid fuel, and char, all of which can be reused, offering high resource recovery potential.

- Incineration primarily generates flue gas and ash, with energy recovery as the main utilization form.

Environmental Impact

- Pyrolysis, due to the oxygen-limited environment, generates fewer harmful substances and is generally more environmentally friendly.

- Incineration, if not properly controlled, may produce pollutants such as dioxins and nitrogen oxides, posing risks to the environment and human health.

Advantages and Challenges of Pyrolysis

Advantage:

- Low environmental risk: The oxygen-free environment suppresses the formation of dioxins and furans, lowering environmental and health risks. Moreover, emissions of CO₂, NOₓ, SOₓ, HCl, and other hazardous pollutants are generally lower.

- High level of resource recovery: Pyrolysis maximizes the recovery of valuable gases, oils, and char, aligning well with the principles of a circular economy.

- Wide applicability of products: Unlike incineration mainly used for electricity generation, pyrolysis products have multiple uses. Pyrolysis oil can serve as fuel or be upgraded to non-standard diesel, while biochar is applied in carbon removal, soil improvemnet, building materials and more.

Challenges:

High capital investment and operating costs, with complex technical operation

Advantages and Limitations of Incineration

Advantage:

- Technological maturity and operational stability: After decades of development, incineration systems have accumulated extensive engineering experience and are well suited for large-scale, continuous operation.

- Significant waste volume reduction: Incineration can reduce waste volume by approximately 70%–90%, greatly decreasing the demand for landfill space.

Challenges:

- Potential formation of dioxins and other pollutants,

- Stricter regulations and compliance risks: Due to considerations for sustainable development, environmental policies globally are leaning towards becoming more stringent. Governments of various countries are raising the bar for environmental standards related to incineration, and they are imposing stricter requirements on the approval process by limiting the number and scale of incineration projects.

- Public acceptance risk: Local communities and residents may resist incineration projects due to environmental and health concerns.

- Limited resource recovery value and Promotes Wastefulness: Incineration solves the current waste problem but doesn’t consider the long-term issue. Having incineration as an option is almost like having a constant excuse to continue throwing objects away because they can always get burned. It compete with material recycling, impeding the recovery of recyclable materials.

Integrated Comparison and Application Recommendations

In practical applications, the selection of appropriate technology should be based on factors such as waste type, treatment scale, environmental requirements, and economic conditions.

- Pyrolysis is more suitable for scenarios that emphasize resource recovery, flexible product utilization, and low pollutant emissions.

- Incineration remains an effective option for the large-scale treatment of municipal solid waste with complex and heterogeneous composition, particularly where stable volume reduction and energy recovery are required.

Looking ahead, the integrated or complementary application of pyrolysis and incineration is expected to become an important strategy for enhancing overall waste treatment efficiency and environmental performance.

Conclusion

Overall, pyrolysis and incineration each possess distinct characteristics and advantages. Incineration, with its technological maturity and high waste reduction efficiency, currently plays a significant role in waste management systems. Pyrolysis, on the other hand, represents an important future development direction due to its favorable environmental performance and strong potential for resource recovery. Through the scientific selection and integration of these two technologies, waste treatment can be advanced toward a greener and more sustainable pathway.