Understanding the main components of the whole set of pyrolysis system is crucial for efficient operation and production. Beston pyrolysis plant is designed with the following parts: feeding system, reactor system, condensing system, exhaust gas dedusting system, discharging system, electronic control system, and other accessories. These systems work together seamlessly to achieve efficient pyrolysis. Customers can customize configurations based on budget and specific requirements.

Part 1: Pretreatment System – Optional Part

The pretreatment system processes materials into smaller and more uniform particles. By increasing the volume of materials filled into the reactor, it makes full use of the reactor’s internal space. Meanwhile, materials will receive more uniform heating. This improves the efficiency of the pyrolysis plant and saves energy.

Components: tyre cutter, wire drawing machine, tyre dicing machine, shredding machine, plastic crusher, etc.

PS: This system is optional. Customers can choose according to the raw material situation. Our professional project consultants will offer you reasonable advice.

Part 2: Feeding System – Diverse Choices

The feeding system transports raw materials to the pyrolysis reactor through mechanical or manual means. There are primarily three methods: manual feeding, screw feeding, and hydraulic feeding. Additionally, a belt conveyor is employed as a supporting component.

- Long feeding time, high manual labor intensity, and batch working;

- No need for complex pretreatment work of raw material, saving equipment procurement expenses;

- Ideal for countries and regions with lower labor costs;

- Can be used in conjunction with belt conveyors or forklifts.

The screw feeder utilizes a motor to drive the screw rotation, for material conveyance. It has the following characteristics:

- Short feeding time, low labor intensity, and suitable for countries or regions with higher labor costs;

- Requires additional purchase of pre-processing equipment for complex raw material preparation;

- Strong screw thrust, allowing materials to fill the furnace more densely;

- Particularly suitable for continuous operation, capable of high-temperature feeding and continuous production;

- Simple and compact structure and convenient operation and movement.

All components, including the hydraulic cylinder, electrical control cabinet, etc., are tightly fixed on the frame.

- Short feeding time and low labor intensity;

- This tyre pyrolysis plant allows for feeding whole tires, tire chunks, coarse crushing, fine crushing, and other materials;

- Strong hydraulic thrust, allowing materials to densely fill the entire furnace;

- Operation and movement are very simple and convenient.

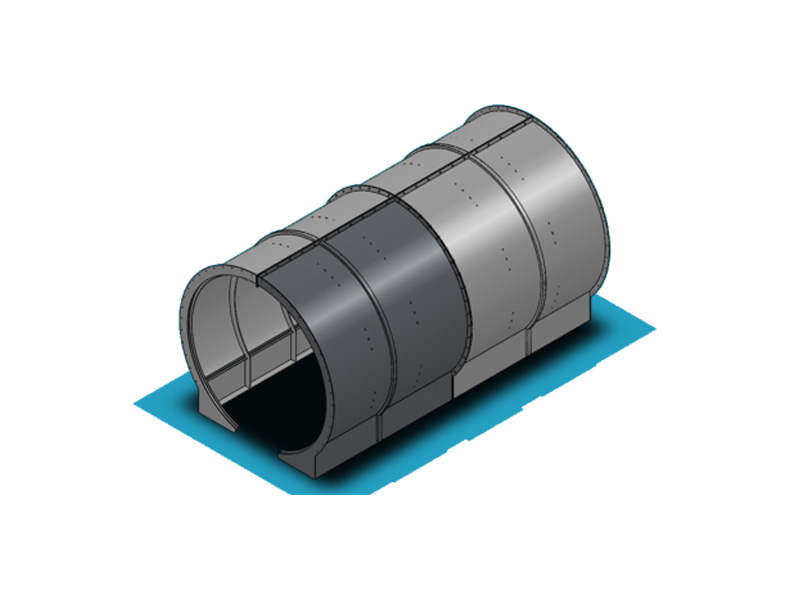

The belt conveyor can be matched with the above three feeding methods to improve feeding efficiency. It is a mechanical device that utilizes friction to continuously transport materials. It mainly consists of a frame, conveyor belt, idlers, drums, tensioning device, and drive device. The belt conveyor can transport materials over long distances. It also has the advantage of a simple structure that is easy to maintain.

Part 3: Reactor System – Core Component

The core of the entire pyrolysis system is the reactor system. Now let’s delve into the key aspects of this core component:

The pyrolysis reactor is the place where raw materials undergo thermal decomposition to produce oil gas in the absence of oxygen. The reactor rotates under the action of the driving system, realizing the movement of materials. The raw materials continuously absorb heat in the reaction and start to produce oil gas after reaching the pyrolysis temperature. The design and performance of the reactor determine the efficiency and product quality of the pyrolysis process.

The driving system uses an electric motor to drive a cylindrical gear reducer, providing power for the operation of the reactor.

The casing is installed on the outer side of the reactor, serving the purpose of insulation and energy conservation.

The base is where the fuel is burned to provide heat for the pyrolysis reactor. It serves to support and secure the reactor.

Part 4: Catalytic System – Exclusive Patent for Plastic Pyrolysis(Optional)

Catalytic pyrolysis is a patented technology to address wax oil blockages during plastic pyrolysis. It typically involves either a dual-tower or single-tower configuration.

Catalytic tower: It functions by using catalysts to decompose the wax oil generated during the plastic pyrolysis process. This improves the quality of the pyrolysis oil and addresses the issue of wax blockages. Following catalytic treatment, the oil gas proceeds into the condensing system for further processing and separation.

Part 5: Condensing System – Oil & Gas Separator

The condensing system separates and collects the pyrolysis oil gas from the reactor. It includes:

The manifold is used to separate heavy particles and light particles of oil gas. There is a draining valve at the bottom of the manifold to drain residue and a tube on the top to discharge oil gas to the condenser.

The oil tank serves the purpose of storing oil and separating gas from liquid. Under the influence of gravity, the liquid oil formed during cooling flows into the oil tank for storage.

The hydroseal functions by utilizing water pressure to prevent backfire and purify combustible gas. Flames entering the tank cannot propagate, thus averting hazards.

The oil gas condenser plays the role of cooling oil gas. It is an important part of pyrolysis equipment and is directly related to the oil yield. You can choose one way according to your needs.

Oil gas from the manifold enters the vertical condenser, where it cools down to form liquid pyrolysis oil and non-condensable syngas. Then the liquid oil enters the oil tank. Water is used as the cooling medium in the cooling process to transfer heat. The vertical condenser features advantages such as a simple structure, easy maintenance, and a relatively large cooling area.

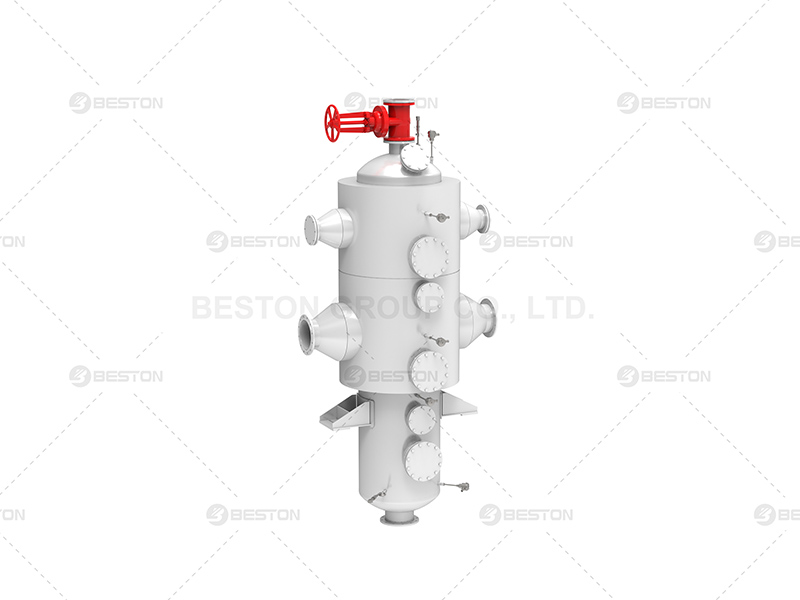

The 3-in-1 condenser integrates oil gas condenser, oil storage tank, and hydroseal. It has the following advantages:

- Convenient for transportation and installation, effectively shortening the installation period.

- The condensing pipeline is relatively thick, reducing the risk of blockages and facilitating cleaning.

- Occupies minimal ground area.

- Offers a large oil storage capacity.

- Equipped with dual hydroseals, significantly enhancing anti-backfire performance.

Part 6: Dedusting System – Environmental Compliance Guarantee

The dedusting system collects and purifies the flue gas from the reactor to achieve standard emissions. The smoke and dust produced in combustion chamber goes through flue condenser, which reduces the temperature to about 140 degrees; the cooled smoke and dust (soot) was introduced to the water tank by the induced draft fan, passes through the impacting of water, then through the adsorption of Boer magnetic, water spray, to make the temperature blow 100 degrees; then discharge the smoke through the chimney, in line with the emission of Europe standards.

The chimney condenser reduces the temperature of the flue gas by exchanging heat with circulating cooling water.This serves to protect the bearings of the induced draft fan, thereby extending the service life of the induced draft fan.

The water tank provides water for the spray system of the spray tower and facilitates water recycling.

The draft fan is used to exhaust the hot flue gas generated inside the furnace and to maintain a certain negative pressure within the reactor by continuously supplying air. This helps ensure a stable working environment inside the furnace.

The chimney is a ventilation structure. It is typically vertical or as close to vertical as possible to ensure the smooth flow of flue gas and its discharge into the air.

The spray tower, also known as a dedusting tower, primarily serves to remove impurities in the flue gas. It provides two dust removal methods.

- Magnetic ring packing dust removal: The packing adopts ceramic Bohr magnetic ring, which has the advantages of large flux, low resistance, high separation efficiency, and large operating flexibility. In general, it is 50%-100% larger than ordinary Raschig rings. When the hot air passes, the filler magnetic ring has a damping effect on the hot air and separates the larger particles of dust. The spray water wets the surface of the magnetic ring. When the hot air passes, the wet magnetic ring surface absorbs the smaller particles of dust and sprays at the same time. The shower pump sprays water evenly to wash the magnetic ring.

- Spray water dust removal: The spray water pump supporting the dust removal tower pumps water from the base of the dust removal tower, and the water in the dust removal device is sprayed into a mist through the nozzle. The spray dust collector collides, intercepts, and condenses, and the dust particles fall down with the droplets. This kind of dust collector has a simple structure, low resistance, and convenient operation. The spray head in the tower sprays water evenly to separate the fine particles in the hot air. In the dust removal base, the dust and impurities are deposited, and the clear water is separated by the partition, and the separated water is recycled for the water mist dust removal.

Part 7: Discharging System – Carbon Black Collector

The discharging system discharges carbon black from the reactor through an internal screw. It achieves full automation, cleanliness, and pollution-free operation, saving time and effort. Components include:

Its principle is the same as that of a screw conveyor. It moves the carbon black to achieve discharging transportation. It mainly includes a drive device, spiral shaft, spiral blades, and spiral casing. The structure is simple and compact, ensuring convenient transportation.

The high-temperature ball valve is closed during production, preventing oil gas from escaping through the discharger. When discharging, it is opened to allow carbon black to be discharged from this point.

It can lower the temperature of the carbon black and is an optional component. The water cooling system can share a set of equipment with the oil gas condenser, requiring only the addition of corresponding valves, water pumps, and pipelines.

Part 8: Electronic Control System – Control Center

Electrical control cabinet: It controls the switches and operation of various motors within the pyrolysis system. It displays the temperature and pressure of key components, providing data for production operations.

Part 9: Other Accessories

In addition to the mentioned critical components, the whole set of plastics/tyre/oil sludge pyrolysis plant also involves several other accessories, such as

- Cooling tower: cooling the cooling water of the cooling system for water recycling;

- Burner: mixes fuel and air in a controlled manner to provide the initial thermal energy for the reactor;

- Blower: conveying air to the combustion chamber to ignite combustible gases to heat the reaction vessel;

- Burning room: burns off excess combustible gas to enhance safety and reduce pollution;

- Airbag: stores the combustible gas produced by the pyrolysis equipment to provide fuel for subsequent production;

- etc.