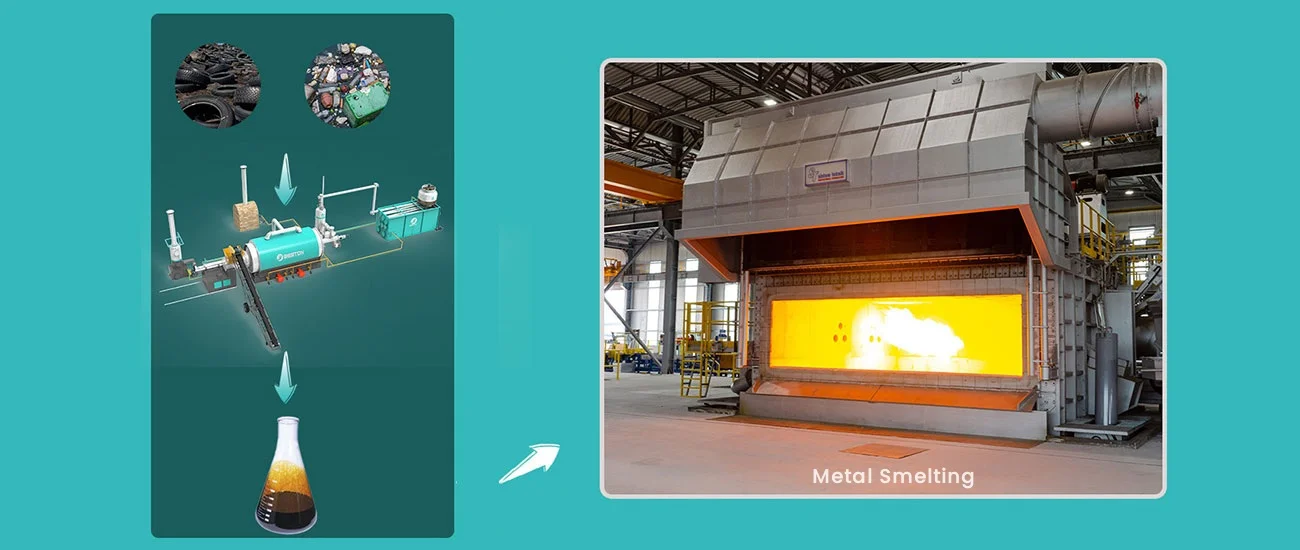

Pyrolysis plant in South Africa is primarily used to recycle waste plastics, waste tires, and oil sludge into pyrolysis oil. This alternative fuel can be utilized in fields such as metal smelting and boiler power generation. Investors have recognized this opportunity in South Africa and have initiated practical projects. Continue reading to learn how Beston Group cooperates with these investors.

Pyrolysis Plant in South Africa: Plastic/Tyre/Oil Sludge Recycling Solution

In South Africa, a pyrolysis plant is an industrial facility that offers effective solutions for:

Plastic Recycling

- Local Challenge: South Africa generates between 2.37 million and 2.4 million tonnes of plastic waste annually. With a per capita plastic waste generation of around 41 kg/year, South Africa exceeds the global average of 29 kg/year.

- Plastic Types for Pyrolysis: PE, PP, PS, ABS, and other plastics without chlorine and oxygen.

- End Pyrolysis Products: plastic pyrolysis oil, solid residues, combustible gas.

Tyre Recycling

- Local Challenge: South Africa generates between 12 million and 16 million waste tires annually. In terms of weight, an estimated 170,266 tonnes of waste tyres are produced each year.

- Tyre Types for Pyrolysis: various discarded tires from vehicles

- End Pyrolysis Products: tyre pyrolysis oil, carbon black, steel wire, and combustible gas.

Oil Sludge Recycling

- Local Challenge: In 2023, the South African government announced plans to intensify oil and gas exploration to enhance energy security and industrialization. This will lead to a substantial amount of hazardous oil sludge that requires proper management.

- Oil Sludge Types for Pyrolysis: drilling cuttings, tank bottom oil sludge, scum bottom mud, oil-contaminated soil, etc.

- End Pyrolysis Products: pyrolysis oil, combustible gas, and other solid residues.

Customer Investment Practice: 2 Sets of Pyrolysis Plants in South Africa in 2023

Parameters of Pyrolysis Plant for Sale in South Africa

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

Usage Instructions of Pyrolysis Plant in South Africa

BLJ-16 Batch Pyrolysis Plant in South Africa

BLl-30 Continuous Pyrolysis Plant in South Africa

Operating an oil sludge/plastic/tyre pyrolysis plant in South Africa requires trained personnel and adherence to safety regulations. A simplified overview of the process includes:

- Feedstock Pretreatment: Ensure the size of the waste material is appropriate for the specific pyrolysis machine model.

- Feeding: The prepared feedstock is loaded into the pyrolysis reactor manually or automatically.

- Pyrolysis Process: The reactor is heated to the designated temperature range in an oxygen-depleted environment, causing the thermal decomposition of the waste material.

- Product Collection: Collect the resulting liquids (pyrolysis oil), and solid products for further processing or storage. Combustible gas produced during pyrolysis usually fuels the reactor directly without the need for additional collection by workers.

Introduction to Components of Pyrolysis Plant for Sale in South Africa

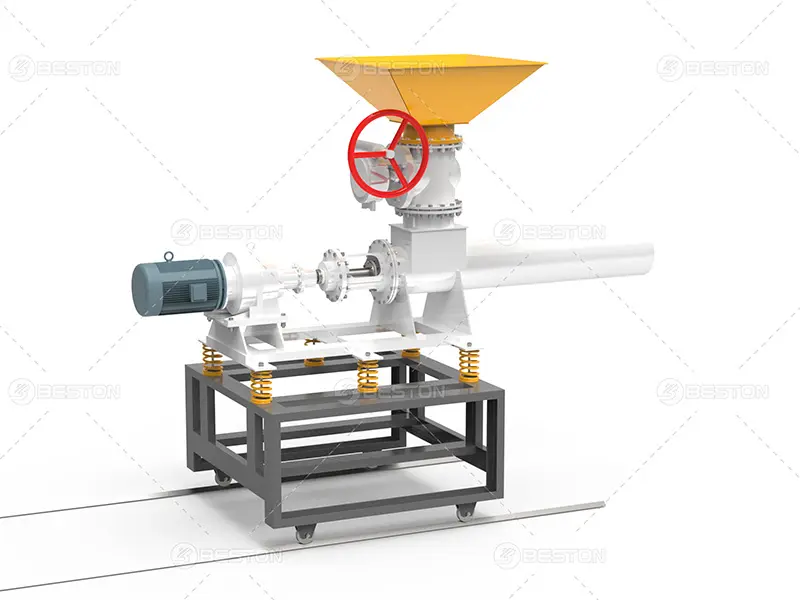

Screw Feeder

Its function is to transport raw materials for the reactor. The selection of a screw feeder requires pretreatment of the sludge. This feeding method can improve reaction efficiency and save working hours and manpower.

Reactor

The reaction kettle rotates under the work of the driving device. At first, the oil sludge absorbs heat in the reactor. Then, it reaches pyrolysis temperature. Ultimately, the sludge is pyrolyzed to produce oil and gas.

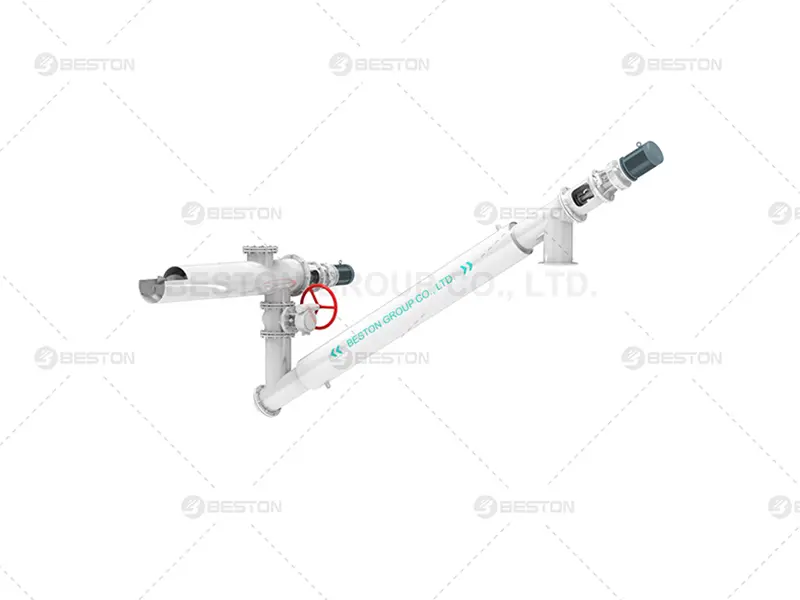

Manifold

First of all, the manifold buffers the oil gas from the pyrolysis reactor, so that the oil gas can enter the oil gas condenser evenly. Secondly, it plays the role of gas-liquid separation, separating gas and heavy oil.

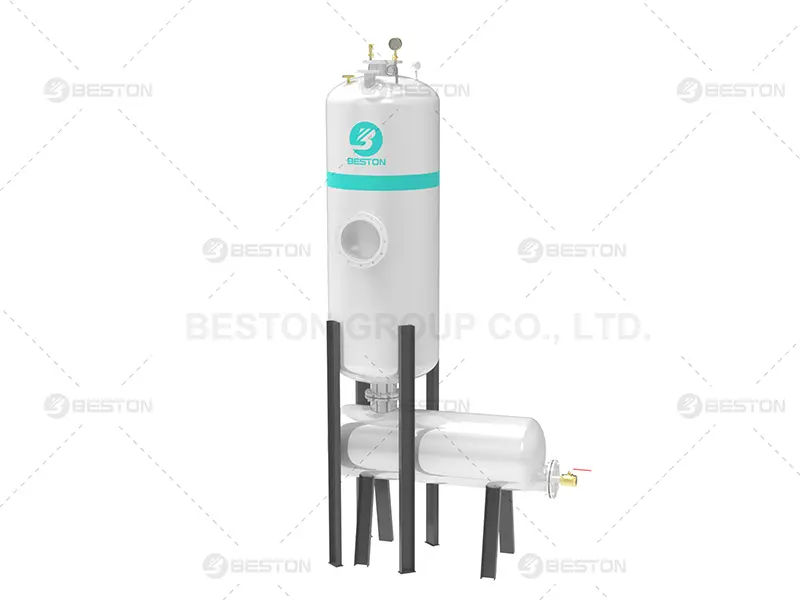

Vertical Condensor

The high-temperature oil gas is condensed into liquid through the oil passage condenser. This part is directly related to the oil yield of the cracking equipment. Under the action of gravity, the liquid oil formed by cooling flows to the oil tank for storage.

Water Seal

Under the action of the pressure generated by the reactor, the combustible gas that cannot be cooled enters the water seal. The function of the water seal is to prevent tempering. At the same time, it can also purify combustible gas.

Oil Gas Condensation Module

It is a device with an integrated design of the oil gas condenser, oil storage tank, and water seal. It occupies less land and has more oil storage capacity. Not only that, the module is equipped with double water seals, which makes the anti-temper performance more reliable.

Flue Gas Condenser

The water pump provides circulating cooling water to the flue condenser. After the high-temperature gas passes through the equipment, it undergoes heat exchange with the cooling water. This reduces the temperature of the hot air and provides protection for the bearings of the induced draft fan.

Dedusting Tower

The dedusting tower processes the flue gas through the spray system. In addition, the water tank provides the water source for the dust removal system. The chimney ensures a smooth discharge of gas into the air.

Discharger

At the end of the reaction, the temperature drops. At this time, the screw discharger discharges carbon black. Meanwhile, the water-cooled discharger can realize cooling of carbon black in a high-temperature environment.

Favorable Factors for Investing in Pyrolysis Plant in South Africa

As the second-largest economy in Africa, South Africa offers a relatively stable investment environment with well-established financial, legal, and infrastructure systems(transportation networks, energy grids, etc.). These conditions are crucial for the smooth operation of pyrolysis facilities.

South Africa is undergoing economic growth and industrialization, bringing increasing energy demands. Pyrolysis Plant in South Africa not only helps manage waste but also produces pyrolysis oil fuels and other chemical feedstocks to meet market demands.

South Africa’s environmental policies encourage the adoption of sustainable recycling technologies, including pyrolysis. For instance, the South African Plastics Pact sets targets for plastic packaging recycling (100% reusable, recyclable, or compostable packaging; 70% effective recycling of plastic packaging).

The relatively low land and labor costs in South Africa contribute to reduced startup and operational expenses for pyrolysis projects, enhancing their economic viability for investors.

The R&D and manufacturing of pyrolysis equipment require high-level technical support. Internationally, pyrolysis technology is mature and widely commercially deployed. The South African government supports such projects to meet industrial upgrading needs, facilitating easier project approvals.

South Africa’s strategic coastal location and its status as an emerging market attract international investors, providing extensive financing channels for pyrolysis projects.

Start Your Pyrolysis Business in South Africa Now

Beston Group is your go-to expert in pyrolysis. We boast extensive project experience with over 100 successful cases worldwide. We specialize in innovative technologies, holding patents like catalytic pyrolysis dewaxing technology. We provide comprehensive services, including technical consulting, installation guidance, operational training, etc. Contact us today to set up oil sludge/plastic/tyre pyrolysis plant in South Africa.