Tyre to oil recycling process converts non-biodegradable tyres into useful substances through high-temperature heating. It operates on the principles of environmental protection, sustainable development, and economic viability. Here delve into relevant information about tyre to oil conversion, with a focus on the methodology utilized by industry leader, Beston Group.

Challenge of Waste Tyres Recycling Industry

As everyone knows, improper disposal of tyres leads to environmental pollution, health hazards, and wasted resources. Therefore, it is imperative to advance recycling solutions that are environmentally sustainable and economically feasible.

Challenge in Amount

Every year, 1 billion tyres reach the end of their lifespan. Unfortunately, only 40% are recycled. Moreover, with the continuous manufacturing and usage of vehicles, the number of waste tyres continues to increase, exacerbating the challenge.

Challenge in Tyre Recycling Ways

Conventional disposal methods such as burning, stacking, and landfilling pose severe environmental pollution risks. Retreading for the same batch of tyres is often limited in frequency. Demand for recycled rubber powder is finite, while investment costs remain high. Consequently, there is still a need for more eco-friendly and efficient ways to recycle waste tyres.

Why Choose Tyre-to-Oil as Recycling Solution?

Effective Waste Reduction and Resource Recovery

Tire-to-oil recycling utilizes tyre pyrolysis plant to convert large amounts of tires into oil, carbon black, and steel wire. This process ensures that nearly all components of the tires are recovered, achieving genuine 100% recovery. These end products find applications across various industries, including being reused in the tyre manufacturing industry, fostering a circular economy.

Follow Environmental Principles

The tyre to oil recycling process emphasizes environmental responsibility. Dedusting treatments like water washing, water spray, ceramic ring adsorption, and activated carbon adsorption are employed to treat exhaust gases. This can comply with strict emission standards like those set by the EU. By significantly reducing pollution, this recycling method aligns with sustainability principles.

Economic Viability

Tyre to oil recycling can be economically viable due to several factors. Firstly, it reduces the costs associated with traditional waste management practices, such as landfill fees and transportation expenses. Secondly, the recovered oil and other by-products can be sold or utilized in various industries, generating revenue and creating new business opportunities. Additionally, investing in tire-to-oil recycling facilities can create jobs and stimulate economic growth in local communities.

Pyrolysis Technology Behind Tyre to Oil Recycling Process

At the heart of tire-to-oil recycling is pyrolysis – a thermal decomposition process in the absence of oxygen. The process involves heating shredded tires in a pyrolysis reactor and breaking down the complex hydrocarbons into simpler molecules. The resulting products include fuel oil, which can be further refined into non-standard diesel or gasoline, carbon black used in rubber and plastic industries, and steel wire recovered from the tire beads.

Steps Involved in Tyre to Oil Recycling

- Pre-treatment: Waste tires are collected and shredded to reduce size, facilitating feeding and pyrolysis.

- Feeding: Input shredded waste tyres into the reactor of pyrolysis plant manually or automatically.

- Pyrolysis: Waste tires in the pyrolysis reactor are heated at high temperatures, typically between 280-350°C, causing thermal decomposition and oil gas production. Heavy oil gas particles drop into an oil tank, while lighter oil gas rises and enters a condenser.

- Condensation: Light oil gas is condensed into liquid form through a cooling system, yielding pyrolysis oil.

- Dedusting: Exhaust gas undergoes dedusting treatment and is emitted when achieving environmental standards.

- Residue collection: Residual solids, primarily carbon black, are recovered from the reactor and further processed for reuse.

- Distillation (optional): The pyrolysis oil from tyre recycling can undergo further distillation optimizing its usability and value. It is separated into different fractions such as diesel, gasoline, and lighter oils.

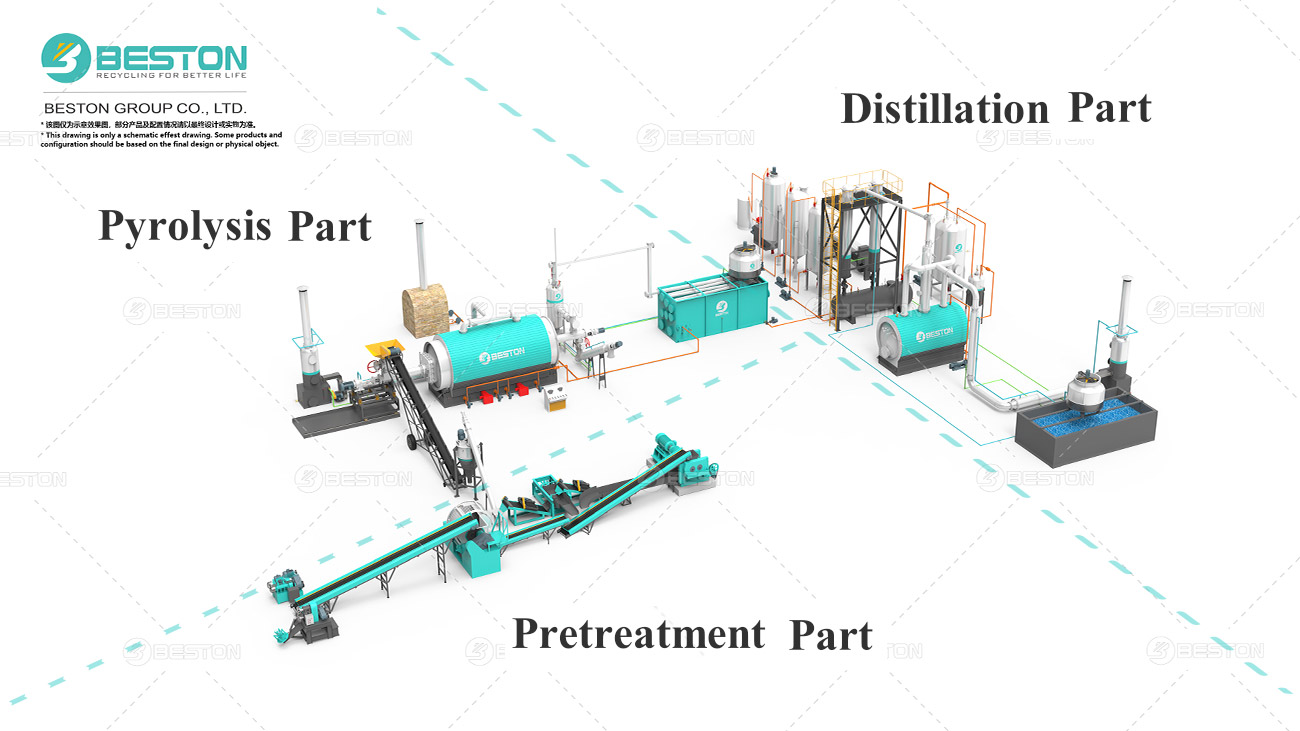

Involved Machine in Tyre to Oil Conversion

Specialized equipment is essential for the tyre to oil recycling process, encompassing key components such as the pyrolysis reactor, condenser, and oil tanks. These units are designed to efficiently break down the tyres and extract valuable resources like oil, carbon black, and steel. Beston Group, a leading manufacturer in this field, offers state-of-the-art machinery designed for efficiency and durability. Here are the key machines involved:

Tyre Pretreatment Machine – Turn Whole Tyre into Small Particles (Optional)

Tyre pretreatment machine transforms whole tyres into small particles, which serves two main purposes. Firstly, it facilitates smooth feeding of the tyres into subsequent reactor. Secondly, this increases the surface area exposed to the pyrolysis process, improving pyrolysis efficiency. Customers can selectively configure this part based on the condition of the tire raw materials.

Tyre to Oil Plant – Turn Tyre into Pyrolysis Oil (Essential)

This machine is the cornerstone of tyre-to-oil conversion. This essential machine utilizes high temperature and low oxygen pyrolysis technology to realize the conversion of tyre into pyrolysis fuel oil.

Distillation Equipment – Improve Pyrolysis Oil quality (Optional)

While pyrolysis extracts oil from tyres, it may contain varying compositions. Distillation equipment offers an optional refinement step to enhance the quality of the crude tyre oil. Through fractional distillation or other refining processes, the tyre pyrolysis oil is separated into distinct fractions based on their boiling points and properties.

Applications of Pyrolysis Oil from Tyre Recycling

The fuel oil obtained through tyre to oil recycling process finds diverse applications across various industries. Common uses include:

- Fuel: Tyre pyrolysis oil can directly substitute conventional fuels in various industrial applications such as boilers, furnaces, and power plants.

- Transportation: Tyre pyrolysis oil that is refined into non-standard diesel and gasoline fractions can power vehicles, reducing reliance on fossil fuels.

- Industrial feedstock: Tyre pyrolysis oil serves as a feedstock for chemical processes, contributing to the production of solvents, lubricants, and other petroleum-based products.

Future Outlook of Tyre to Oil Recycling Process

The tyre-to-oil recycling industry is poised for significant growth as countries prioritize sustainable waste management practices and seek alternatives to fossil fuels. Advancements in technology, process optimization, and market demand are driving innovation in this sector. With continuous research and development, tyre to oil recycling has the potential to become a cornerstone of the circular economy, promoting resource efficiency and environmental stewardship.

Tire to Oil Recycling Project at Beston Group

Beston Group exemplifies excellence in tyre to oil recycling process through its advanced pyrolysis technology and commitment to customer satisfaction. We offer comprehensive solutions for tire recycling on a global scale. Reach out to us today for optimal tire-to-oil solutions!