Tyre pyrolysis process is a thermal process where the cross-linked rubber polymers vibrate and break at specific temperatures in oxygen-free environment, converting them into valuable products: pyrolysis oil, combustible gas, recovered carbon black (rCB), and steel wire. The process involves shredding tires, heating them in a sealed reactor to break chemical bonds, collecting the gaseous and liquid outputs, and separating the solid char from steel wires, creating circular materials for fuel, chemicals, and new tires.

Detailed Tyre Pyrolysis Process: Step-by-Step

Phase 1: Pre-treatment & Feeding

Before the reaction begins, prepare suitable tyre feedstocks to ensure efficiency

- Steel Removal: In continuous plants, remove steel wires during pre-treatment. In batch plants, load whole tyres and extract the steel after pyrolysis.

- Shredding: In continuous plants, shred tyres into 3-5 cm chips for feeding. In batch plants, load whole tyres directly.

A sealed hydraulic or screw feeder then pushes the pre-treated tyres into the reactor for pyrolysis.

Phase 2: Thermal Cracking in the Reactor

Once sealed, the reactor is slowly heated using fuel. Each pyrolysis plant will follow its own heating process. The reactor rotates constantly to ensure even heating of the tyre feedstock (uniform heat transfer).

- 100℃-250℃: Preliminary heating phase, where moisture evaporates and light oil gas begins to emerge.

- 250℃-450℃: Core reaction stage, where the heaviest polymer chains break. Large amount of oil gas emerge. The remaining solid is carbon black.

Phase 3: Oil Gas Condensation

Oil gas travels through a manifold into condensers. The temperature drop converts the oil gas into liquid pyrolysis oil.

Non-condensable combustible gases are scrubbed and redirected back to the furnace as a clean energy source for heating.

Phase 4: Carbon Black Discharge

The remaining solid residue in the reactor is carbon black, which is then discharged through a sealed water-cooling discharger.

Flow Chart of Waste Tyre Pyrolysis Process

Products of Tyre Pyrolysis

Pyrolysis Oil (40% – 45% Yield)

The main components in tyre pyrolysis oil are benzene, toluene, xylene, styrene, dimer pentene, trimethylbenzene, and tetramethylbenzene. These compounds are all useful chemical raw materials.

- As industrial fuel;

- As chemical feedstock for further processing;

- Refined into commercial gasoline and diesel with proper upgrading.

Carbon Black (30% – 35% Yield)

The carbon black mainly comes from the carbon black originally present in tire formulations, contains ash and small amounts of impurities, and is generally classified as crude carbon black.

- It can serve as a reinforcing filler in tires, a pigment for inks, an asphalt modifier, and other applications.

- Deep processing, such as grinding and pelletizing, refines tire pyrolysis carbon black into high-value grades like N330 and N660.

Steel Wire (15% – 20% Yield)

The steel wire comes from the spring steel wire in the tyre. Due to the low temperature and anaerobic environment, pyrolysis treatment has little impact on the performance of spring steel wire, and after collection, it can still achieve high economic benefits for external sales.

Combustible Gas (5% -7% Yield)

The combustible gas generated during the pyrolysis process mainly fuels the pyrolysis reactor itself, thus no need for additional energy.

An Example Plant to Demonstrate Tyre Pyrolysis Process

The figures below illustrate a tire pyrolysis plant in Africa. The images shows the key production line: the hydraulic feeder ① loads the whole tire into the pyrolysis reactor ②. The shredded tires are heated. After heating, at the back end of the reactor, the resulting oil is captured in the oil tank ③. The carbon black is discharged via the water-cooled discharger ④, while steel is extracted.

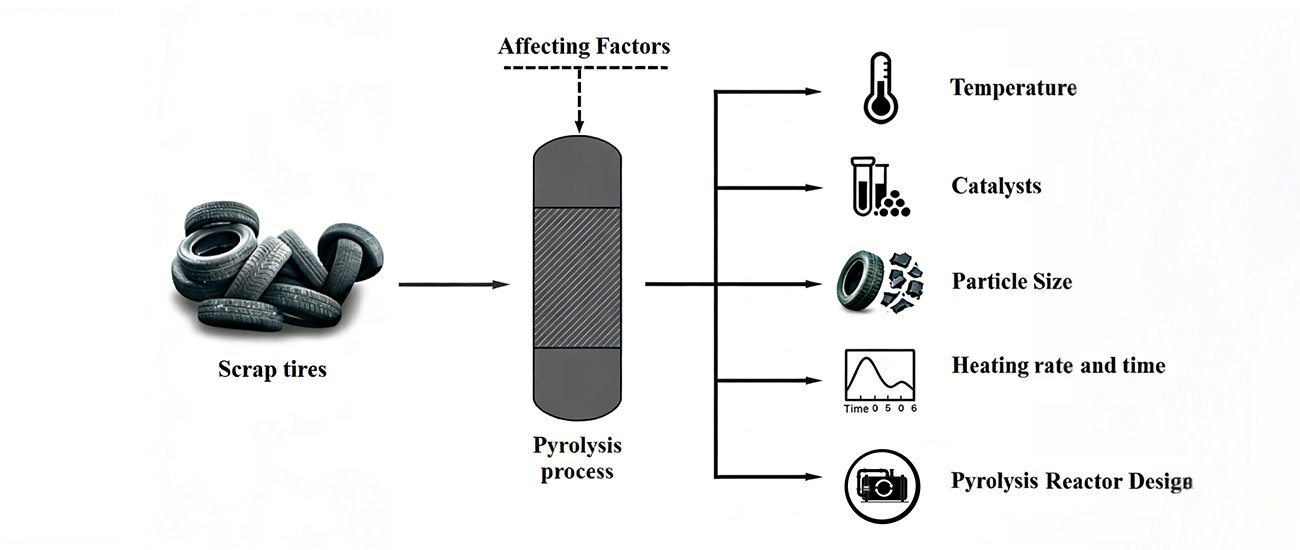

Key Factors Affecting Tyre Pyrolysis Process

There are many factors that influence the tire pyrolysis process, such as reactor structure, raw material, pyrolysis temperature, pyrolysis residence time, heating rate, catalyst, etc. Understanding these factors helps us better comprehend the pyrolysis process and effectively regulate the resulting products.

01 Temperature

Temperature is a critical parameter in tire pyrolysis, directly influencing the efficiency and product distribution. Higher temperatures facilitate the breakdown of high-molecular-weight polymer chains, promoting pyrolysis reactions and the production of pyrolysis oil. However, excessively high temperatures may lead to increased gas production and energy consumption.

| Temperature Range | Reaction Characteristics | Product Characteristics |

|---|---|---|

| Low (< 350°C) | Incomplete decomposition | Low oil yield, high volatile residues in carbon black |

| Medium (400°C – 450°C) | Complete polymer chain breakdown | Peak oil yield, stable carbon black yield |

| High (> 600°C) | Secondary cracking | Decreased oil yield, increased gas yield |

02 Catalysts

Introducing suitable catalysts can lower reaction temperatures, reduce energy consumption. Most importantly, the use of a catalyst can improve the quality of the pyrolysis oil and carbon black, essentially eliminating polycyclic aromatic hydrocarbons (PAHs) from the pyrolysis products, and being environmentally friendly. However, the necessity of using catalysts depends on the specific goals and practical conditions of tire pyrolysis.

03 Particle Size

Particle size is strongly impacts the heat transfer rate, pyrolysis completion time, mass transfer efficiency and energy consumption of the process. Small particles are preferred in pyrolysis because they promote balanced heat transfer and efficient pyrolysis.

- In fast pyrolysis (high heating rate), particle size has minimal impact on product yields.

- In slow pyrolysis (lower heating rate), small particle sizes help improve the product yield.

04 Heating rate and time

By combining temperature and heating rate, the proportions of different components in the pyrolysis products can be controlled. Lower temperatures and slower heating allow for sufficient time for organic molecules to decompose and recombine, increasing the solid content in the products. Higher temperatures and faster heating result in widespread breakdown of organic molecules, increasing the gas component in the pyrolysis products.

Residence time primarily affects the completeness of the pyrolysis reaction and product composition. Longer reaction times help in more thorough decomposition of raw materials, but excessive residence time may lead to further cracking of gases and oils, affecting product quality.

05 Pyrolysis Reactor Design

The design of the reactor directly determines heat and mass transfer efficiency, influencing the overall energy efficiency and stability of the pyrolysis process. Pyrolysis units are typically classified into horizontal rotary kilns and vertical kilns. Horizontal rotary kilns ensure uniform heating and thorough pyrolysis, making them the most common equipment for waste tire oil refining.

Pushing Forward Tire Pyrolysis Development

Beston Group has been dedicated to exploring and optimizing tyre pyrolysis process and technology, driving its application and development. We look forward to collaborating with you to jointly promote the innovation, popularization, and implementation of this green and environmentally friendly technology, contributing to global sustainable development. More dairly news in Linkedin!