Carbon black from tyre pyrolysis is another valuable by-product of the waste tyre to fuel oil conversion. Its versatile applications span various industries, yielding good economic benefits for investors. As a part of tire waste recycling, its production helps realize a sustainable circular economy. Let’s delve into the details.

What Is The Carbon Black from Tyre Pyrolysis?

The tyre pyrolysis carbon black is obtained by heating waste tires to 280°C-450°C in an oxygen-free tyre pyrolysis plant for decomposition. It typically exhibits several characteristics:

- Composition: The carbon black pyrolysis primarily consists of spherical and ellipsoidal carbon particles, along with some fused particles. These particles are formed through the thermal decomposition of organic compounds in waste tires.

- Color: It typically has a black color, owing to its high carbon content and absorption of light across a broad spectrum.

- Particle size: It tends to have relatively fine particle sizes, typically in the nanometer to micrometer range. The specific size can vary based on the pyrolysis conditions and the processing method.

- Surface area: Tyre pyrolysis carbon black has a high surface area due to its porous structure.

- Other properties: It can exhibit properties such as high electrical conductivity, excellent UV resistance, good reinforcement capability in rubber products, and high adsorption capacity.

Wide Uses of Carbon Black from Tyre Pyrolysis

Due to its unique characteristics and properties, tyre carbon black uses is wide. It can be sold directly, bringing profits to enterprises. Or it can be deep processed into high-quality N220, and N330 carbon black, which will have wider applications in different industries.

- Rubber industry: Carbon black is a crucial additive in rubber products, enhancing their hardness, strength, wear resistance, and weather resistance.

- Plastic industry: Carbon black is extensively utilized in the production of plastic goods, serving as a coloring agent, UV stabilizer, and antistatic agent in plastics.

- Ink industry: Carbon black is a key ingredient in various inks, particularly in printing inks, where it serves as a filler and pigment, increasing ink density and opacity, thus enhancing printing quality.

- Coatings industry: Carbon black finds wide application in various coatings, including water-based, oil-based, and powder coatings, enhancing their weather resistance, abrasion resistance, and UV resistance.

- Building materials industry: Carbon black is also employed in the production of various building materials, such as carbon black concrete, carbon black bricks, and carbon black tiles, boasting excellent weather resistance and durability.

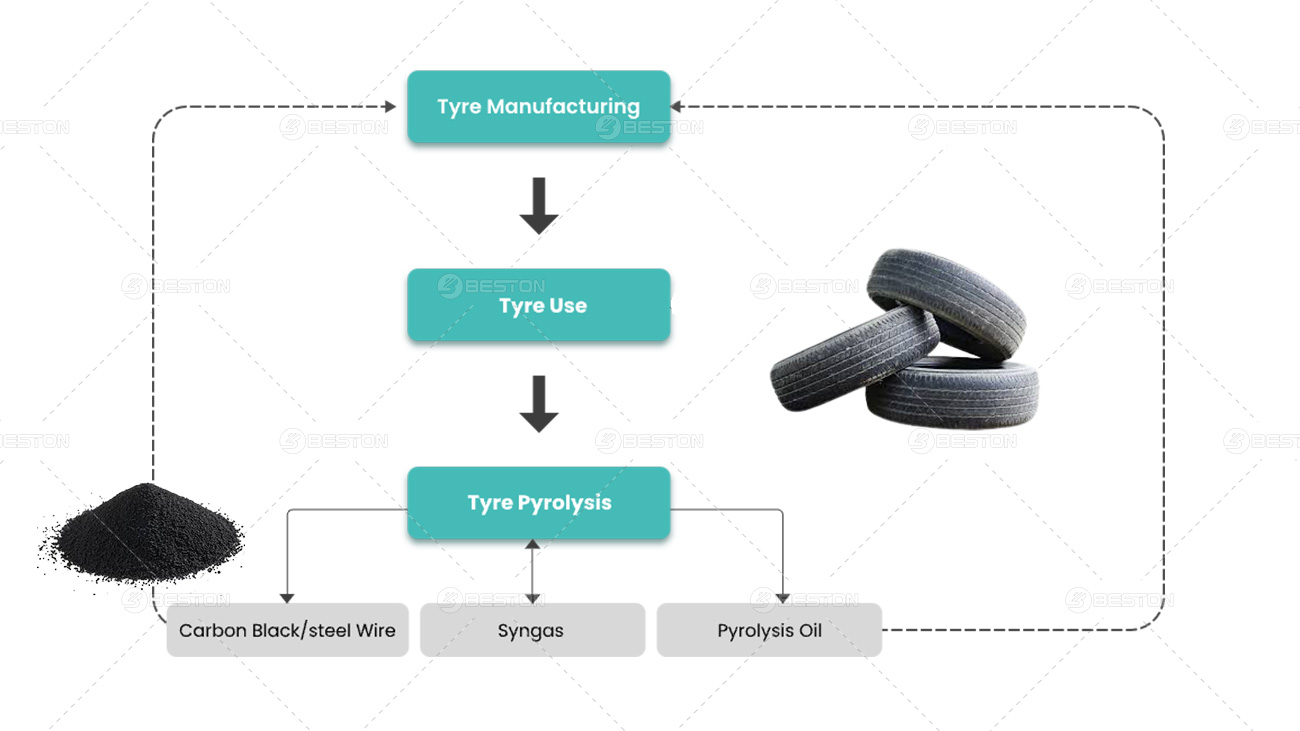

How to Get Carbon Black from Tyre Pyrolysis?

Pyrolysis technology is a technique of thermal decomposition of scrap tires in the absence of oxygen to produce fuel oil, carbon black, steel wire, and combustible gas. Take Beston pyrolysis plant as an example, extracting carbon black from waste tyre usually goes through feeding, pyrolysis, condensation, discharging, dedusting process, etc. For specific tyre pyrolysis process, please refer to the video below.

FAQ about Carbon Black from Tyre Pyrolysis

What is the particle size of tyre pyrolysis carbon black?

The coarse carbon black obtained from Beston pyrolysis plant typically falls within the range of 80 to 100 mesh. The specific particle size is influenced by specific techniques and the type of waste tyre used. (Mesh size indicates the particle size of the carbon black, with larger numbers indicating smaller particles.)

What is the price of pyrolysis carbon black?

The price of carbon black can reach thousands of dollars per metric ton. There are variations in the prices between crude carbon black and refined carbon black. Additionally, factors such as market demand, location, and specific buyers’ and sellers’ negotiated bulk purchase discounts, can influence the price.

What output percentage of carbon black is in tyre pyrolysis?

In the end products of tire pyrolysis, generally 30-35% is carbon black. The rest is pyrolysis oil (35-45%) oil, combustible gas (8-15%), and steel wire (8-15%).

How much is the temperature of cooling carbon black?

Taking Beston machine as an example, the temperature before carbon black cooling ranges from 300 to 450°C. After cooling through one screw-slagging system, it drops to 100-150°C, and after cooling through three screw-slagging systems, it ranges between 50 and 80°C. This ensures safety.

Can we pyrolyze plastics and tires at the same time to get carbon black?

Not recommend. This is because:

- Pyrolyzing tires yield a purer, higher-quality carbon black suitable for further processing.

- Plastic pyrolysis produces solid residues, some of which may be carbon black. The composition of the solid residue can be complex due to the potential inclusion of organic waste such as food residue, paper, or wood.

- Plastic pyrolysis tends to clog systems with wax residues, necessitating catalytic tower systems, unlike tire pyrolysis, which doesn’t face this issue.

In short, mixing waste tires and plastics reduces the value of tyre pyrolysis carbon black. Therefore, it’s recommended to separate them for better product value.

Carbon Black Pyrolysis Promotes Circle Economy

The tyre pyrolysis carbon black plays a pivotal role in tire manufacturing. Following further processing, it can be reintegrated into tire production.

- Firstly, it enhances tire performance, such as grip, durability, and resistance to aging.

- Secondly, it improves thermal conductivity and electrical conductivity, effectively mitigating safety hazards caused by high temperatures or static buildup.

- Thirdly, carbon black used in tyres optimizes the properties of rubber compounds, facilitating tire molding.

The closed-loop economy system, from extracting carbon black from tyre pyrolysis recycling to reusing it in tire manufacturing, demonstrates sustainability by recycling materials instead of relying on new resources. This aligns with the principles of sustainable development and resource efficiency, promoting the advancement of the tire industry towards a circular economy.

Embrace Sustainability with Beston Group

To gain carbon black from tyre pyrolysis, we welcome you to invest in our safe, energy-efficient, environmentally friendly, efficient, and durable pyrolysis equipment. It not only extracts carbon black from waste tires but also can be applied to other waste materials, such as plastic to oil machine, oil sludge pyrolysis plant, and more. Join us to kickstart waste recycling projects and contribute to the pace of sustainable development.