Coconut shell charcoal making machine developed by Beston Group (BST-50S) has passed Puro.earth vetting, producing high-quality biochar that meets EBC standards. It’s a proven solution for the green circular economy and environmental sustainability. There’s no better time to invest in the booming biochar market. Discover efficient coconut shell recycling today!

Parameters of Coconut Shell Charcoal Making Machine for Sale

BST-50S Model

- BST-50S technology vetted by Puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 configuration options

BST-06 Model

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Tested and Proven: 720-Hour Continuous Operation Capability

The Fourth-generation coconut charcoal making machine (biochar machine) gives you safer and longer continuous operation than ever. An optimized tar-free and dust self-cleaning system enables incredible 720 hours of uninterrupted operation. Find the technology breakthrough process!

BST-50S Coconut Shell Charcoal Machine Passed Puro.earth Vetting

Our BST-50S model coconut charcoal making machine has been vetted by Puro.earth, confirming it meets international standards for carbon removal projects. This certification enables your production to qualify for carbon trading systems. It also enhances your eco-friendly image while generating additional economic value. Contact us to inquire about the coconut shell charcoal making machine price!

BST-50S: Ready to Support Your Carbon Removal Project

6000 tons

biochar output annually

12000 tons

sequestered CO₂ annually

$1.8 Million

carbon credit revenue

Benefits of Coconut Shell Charcoal — Cross-Industry Applications

Coconut shell biochar, holds significant potential in addressing climate change. Plants absorb CO₂ from the atmosphere through photosynthesis. When coconut shells are pyrolyzed into biochar, the carbon is stabilized and stored within the molecular structure of the biochar. This prevents the carbon from being released back into the atmosphere as CO₂.

- Agricultural Carbon Removal: Adding biochar to soil locks carbon in the ground for hundreds or even thousands of years, reducing CO₂ in the air and improving soil fertility.

- Construction Industry Removal: Biochar can be incorporated into building materials (e.g., concrete, bricks, insulation materials) to enhance properties. This helps create low-carbon, green buildings while sequestering carbon.

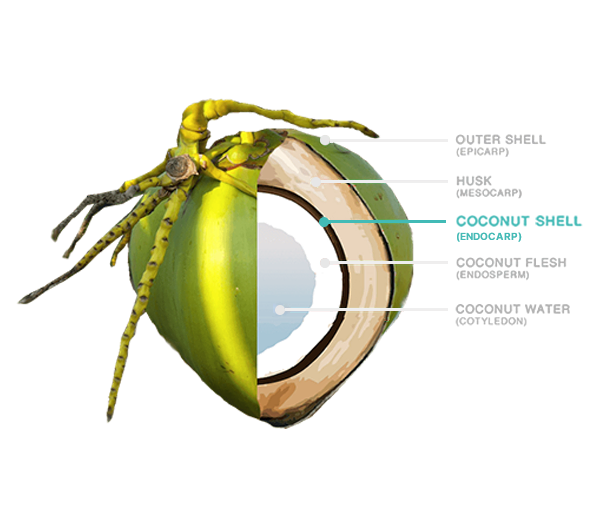

Coconut shells account for 30%-40% of the total weight of a coconut. Their use helps drive the coconut industry chain towards a “waste – resource – reuse” circular economy, aligning with the principles of a circular economy.

- Soil Improvement: Coconut shell charcoal can improve soil structure, increase water retention and aeration, while providing essential nutrients to support sustainable agricultural production. This creates a closed loop within the coconut plantation industry.

- Alternative Fuel: The Circular Economy of Coconut Food Processing: In coconut food processing plants, the combustion of coconut shell charcoal can provide energy for drying or heating production. This reduces dependence on fossil fuels. This forms a closed loop specific to the coconut food processing industry.

- Green Smelting Reductant: Coconut shell charcoal is an excellent alternative to coal in metal smelting, efficiently reducing metal ores with minimal pollution.

- Animal Feed Additive: Coconut shell biochar helps eliminate toxins from animals’ digestive tracts, improves digestion, and boosts immunity. It also significantly reduces methane emissions in ruminants, contributing to a lower carbon footprint.

- Premium BBQ Charcoal: With its high purity and excellent combustion efficiency, coconut shell charcoal is the preferred choice for premium BBQ charcoal. It provides consistent and long-lasting heat while minimizing smoke and odors, making it highly sought after in the high-end market.

Coconut Shell to Biochar: From Raw Material to Final Product Analysis

Why Coconut Shells Are Ideal for Charcoal Production

- High Carbon Content: Coconut shells are rich in lignin and cellulose, resulting in a higher fixed carbon yield during biochar pyrolysis.

- Renewable & Sustainable: Coconuts are grown abundantly in tropical regions, and their shells are a byproduct of waste. Coconut charcoal machine is a sustainable way to valorize waste.

- Low Ash Content (0.5%-2%): This means coconut shell charcoal has high purity, with minimal residue after combustion. This makes it more suitable for high-precision applications such as food processing and industrial smelting.

- Hard and dense structure: Coconut shells are made of tightly interwoven fibers, making them resistant to breakage during carbonization, producing dense and durable charcoal.

- Natural Porosity: The fibers of coconut shells contain numerous micron-sized pores, which expand after pyrolysis. This enhances the charcoal’s adsorptivity and increases its application potential.

| Load capacity | EBC Standard | German Laboratory | Chinese Laboratory |

|---|---|---|---|

| H/C Molar Ratio | <0.4 – 0.7 | 0.45 (Generally Meets All Application Standards) | 0.11 – 0.32 |

| Heavy Metal | Depends on Specific Application | Fully Meet All | Fully Meet All |

| PAHS-8 | Depends on Specific Application | Fully Meet All | / |

| PAHS-16 | <6 mg/kg | Compliant with EBC-Feed, Urban, Basic Material Slightly above EBC Feed-Plus, Agro-Bio, Agro | 0.2 mg/kg |

How to Make Coconut Shell Charcoal?

01 Pretreatment (Optional)

02 Feeding

03 Pyrolysis

04 Syngas Recycling

05 Charcoal Collection

06 Waste Gas Treatment

07 Charcoal Briquetting(Optional)

Sustainable Performance of Coconut Shell Charcoal Making Machine

Consistent and Efficient Operation

- Tar & Wood Vinegar Self-Cleaning System: It prevents blockages caused by tar, wood vinegar, and other substances. This ensures stable operation of coconut charcoal machine for 7200 hours annually.

- Dual-cylinder Rotatory Reactor: It ensures a processing capacity of over 10 m³ per hour. It also fully carbonized coconut shells into high-quality biochar.

Environment Compliance Emissions

- Low nitrogen combustion: Optimized combustion process meets greenhouse gas standards.

- Advanced gas treatment: Multi-stage dust removal, desulfurization, and denitrification meeting strict European limits.

- Sealed combustion: Ensures full fuel burning and prevents gas and dust leaks to reduce pollution.

Safe Production Assurance

- Explosion-proof parts: Water seals, valves, and relief ports for safer operation.

- Micro-negative pressure: Prevents excess pressure inside the coconut charcoal making machine.

- Electrical control cabinet with alarms: Monitors operation and alerts to faults.

- Other designs.

Global Cases of Coconut Shell Charcoal Making Machine in Use

Coconut Shell to Charcoal: Supports Sustainable Development Goals

Environmental Dimension: Sustainable Waste Conversion & Carbon Reduction

- SDG 12 – Responsible Consumption and Production: Turns coconut shells into high-value biochar products, reducing improper management, and enabling resource circularity.

- SDG 13 – Climate Action: Coconut charcoal machine employs low-emission technologies (e.g., flue gas dedusting systems) to reduce carbon emissions. Additionally, coconut shell biochar for carbon removal application mitigates global warming.

- SDG 15 – Life on Land: Coconut shell biochar improves soil quality, prevents land degradation, and supports healthier ecosystems.

Economic Dimension: Value Chain Extension and Industrial Upgrading

- SDG 8 – Decent Work and Economic Growth: The coconut industry will extend its value chain from primary processing to high-value charcoal production, boosting incomes for farmers and processors and creating more jobs.

- SDG 9 – Industry, Innovation, and Infrastructure: Introducing modern coconut shell charcoal making machine promotes domestic technology upgrades, with improvements in automation, energy efficiency, and overall productivity.

Social Dimension: Community Development and Knowledge Transfer

- SDG 1 – No Poverty: In major coconut-producing regions, smallholder farmers can earn additional income by collecting and selling coconut shells as a secondary source of livelihood.

- SDG 4 – Quality Education: Implementing training programs on coconut shell biochar production application enhances the skills of community members, empowering them with greater employability.

Looking Forward to Cooperating with You

Beston Group, a reliable manufacturer of coconut shell charcoal making machine, is ready to tailor the perfect solution for your project. Take the first step toward success with us today. Stay connected and catch our latest news daily on LinkedIn!