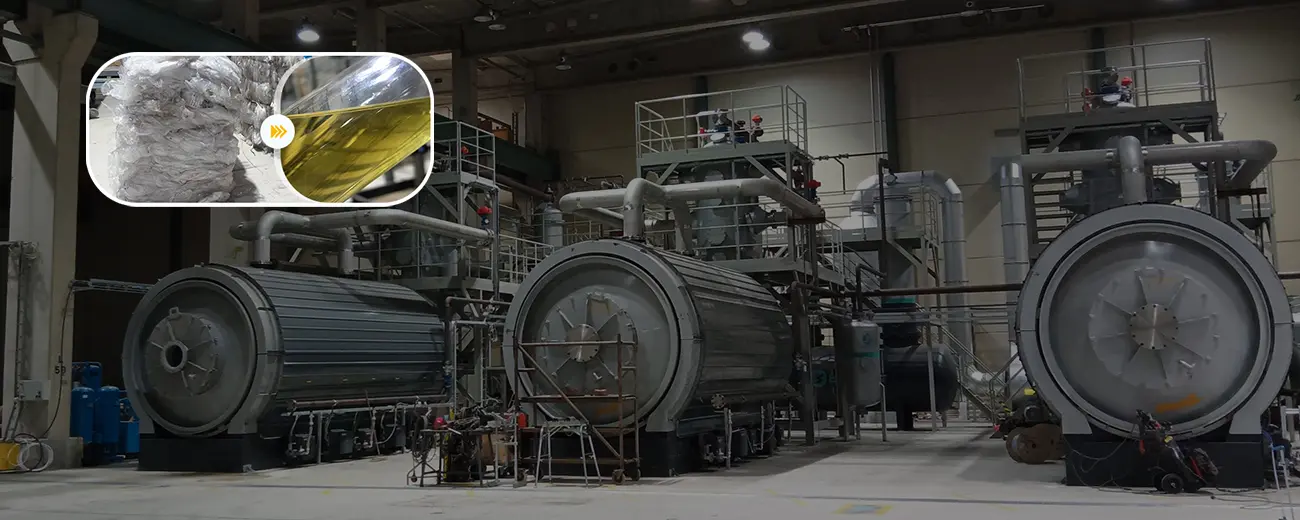

Faced with severe plastic pollution, plastic pyrolysis plant is becoming an effective waste reduction and recycling solution. It can tackle plastic pollution crisis by converting plastic waste into valuable pyrolysis oil. Now please read to learn about this new technology and find new business opportunities. Welcome to contact Beston Group to get an effective plastic pyrolysis solution.

What Is a Plastic Pyrolysis Plant?

A plastic pyrolysis plant uses heat in the absence of oxygen to break down waste plastics into valuable resources like fuel oil, carbon black (solid char), and combustible gas. It offers an eco-friendly way to manage plastic pollution and create energy and chemical feedstocks, transforming hard-to-recycle plastics into usable products for industries or power generation. These facilities are crucial for sustainable waste management.

How Does Plastic Pyrolysis Equipment Work?

01 Feeding

According to the equipment configuration, waste plastics are fed into the reactor manually or through a screw feeder/hydraulic feeder. Seal the feeding inlet door tightly.

02 Pyrolysis

- Heat the reactor by using coal, charcoal, fuel gas, wood etc. as heating materials.

- Wait for pyrolysis temperatures to rise between 280 and 450°C. Heating process initiates a series of decomposition and volatilization reactions, ultimately yielding large amount of oil-gas mixture.

03 Oil Gas Treatment

The oil gas coming out from the reactor then goes to condensing system.

- Most of the light particles of oil gas liquefies into pyrolysis oil.

- Heavy particles of the oil gas (mainly oil dregs) will be repushed into the reactor for re-pyrolysis.

- Un-condensed gas is recycled back to combuster for usd as fuel to sustain the pyrolysis process.

04 Solid Residue Discharge

Once cooled, collect solid residues by automatic discharging system or manually.

05 Combustible Gas & Exhaust Gas Treatment

Exaust gas will go through multiple dedusting and emit when achieving required environmental standards. You can choose EU standards dedeusting configuration.

Selection Guide of Plastic Raw Materials to Pyrolysis

In fact, not all plastics are suitable for pyrolysis. So here is the information about acceptable and unacceptable plastic raw materials for you. Please read.

Kindly reminder: Sample testing is available. If you’re unsure whether your plastic is fit for pyrolysis, you can send us intact, leak-proof samples. Each sample should have a diameter under 2cm and weigh at least 5kg per type.

Acceptable Waste Plastic Types

Acceptable Waste Plastic Types

- PE (Polyethylene);

- PP (Polypropylene);

- PS (Polystyrene);

- ABS (Acrylonitrile Butadiene Styrene);

- Others.

Unacceptable Waste Plastic Types

Unacceptable Waste Plastic Types

- PET (Polyethylene Terephthalate);

- PVC(Polyvinyl Chloride).

NOTE: The two are unacceptable because their pyrolysis produces toxic gases and low oil yield.

3 Pyrolysis Oil Product to Get and Apply

Catalytic Pyrolysis Oil

Through catalytic pyrolysis technology, waxy and unstable components has been reduced in pyrolysis oil. Catalytic pyrolysis oil has such applications:

- Can be directly used as an industrial fuel

- Utilized for the production of chemical feedstocks, such as BTX

- Used as a refinery feedstock, undergoing hydrotreating for further upgrading and utilization

Naphtha

Naphtha is source from integrated pyrolysis + distillation technology and combustible gas-to-naphtha conversion technology. It has such applications:

- Used as a steam-cracking feedstock for the production of ethylene and propylene

- Applied in the chemical industry for the manufacture of plastics, synthetic rubber, and solvents

- Partially substitutes conventional fossil-based naphtha, supporting plastic circular economy initiatives

Non-Standard Diesel

Non-standard diesel is source from integrated pyrolysis + distillation technology. It has such applications:

- Used as fuel for industrial boilers, kilns, and heating systems

- Applied as fuel for self-use generators in mining areas and industrial plants

- Can be further upgraded to standard diesel through deep hydrotreating

Plastic Pyrolysis Oil Yield – from Different Types of Plastic

Now please take a look at the plastic pyrolysis oil yield of different types of plastics. For better oil yield, it is advisable to process a single type of plastic. PE/PP/PS are good options. Utilizing pyrolysis to process mixed plastics is also possible, but it will require more process control and separation steps.

Catalytic Pyrolysis Technology of Plastic Pyrolysis Plant

01 Industry Challenge: Wax Formation

In common plastic pyrolysis, certain feedstock compositions or improper reaction conditions produce paraffin wax. It is a high-viscosity solid at room temperature. The wax easily sticks to equipment’s inner surfaces, causing blockages and operational issues.

02 Technical Solution: Catalytic Pyrolysis

This patent utilizes catalytic tower design and special catalysts to decompose wax oils produced during plastic pyrolysis. Beston Group offers 2 configuration solutions: single or dual-catalyst tower design. Contact us to inquire plastic to oil machine!

03 Key Benefits of Catalytic Plastic Pyrolysis

- 200% Increase in Production Efficiency: Prevent wax oil clogging pipes, ensuring smooth machine operation and reducing maintenance needs.

- ISCC-Compliant Pyrolysis Oil Output: 100% liquefying wax oil, enhancing pyrolysis oil quality. Support customers in meeting international sustainability standards (ISCC) and strengthen market competitiveness.

- Enhanced Operational Safety: Reduces pressure fluctuations risks caused by clogged pipes, enhancing equipment safety during operations.

Multiple Models of Plastic Pyrolysis Machine to Choose

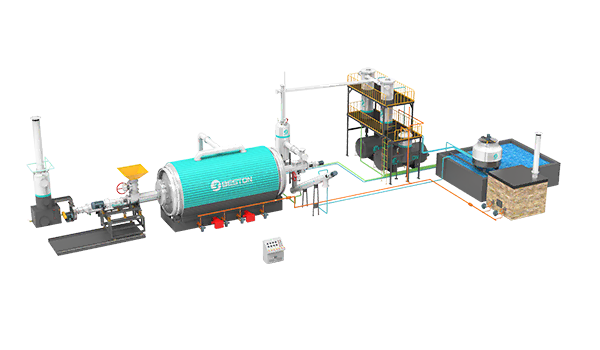

BLL-30 Model Recommend

- Process 6,000 tons plastic waste annually

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get project approval

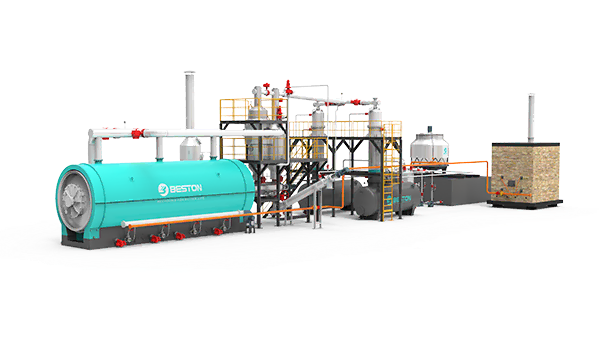

Batch Type: BLJ-20

- Process 4,000 tons plastic waste annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons plastic waste annually

- 1 furnace/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

BLJ-20 Plastic Pyrolysis Plant: Latest Technical Breakthrough

Fractional Distillation Technology

This technology allows simultaneous separation and collection of naphtha (< 200℃) and non-standard diesel (>200℃).

- increases product value;

- no need for additional distillation equipment;

- lowers operating costs.

Large-capacity Pyrolysis Reactor (ø2800*10000)

The large-capacity plastic pyrolysis reactor can process 12–13 tons of plastic waste per day. For your pyrolysis projects, this means:

- faster processing cycles;

- higher return on investment;

- stronger market competitiveness.

Thermal Dynamic Sealing & Flexible High-temperature Insulation Technology

The integrated technology greatly enhances machine and worker safety, delivering:

- superior furnace sealing, no oil-gas leaks

- no open flames & minimal thermal hazards

- stable furnace temperature

BLL-30 Plastic Pyrolysis Plant: Latest Technical Breakthrough

Oil-Gas Anti-Polymerization Condensation Technology

This technology rapidly reduces oil-gas temperatures, effectively preventing olefin polymerization and pipeline blockages.

Key data highlights:

- 30-day continuous operation

- 6000 tons of annual processing capacity

Flue Gas Recycling + Combustion Air Preheating Technology

Hot flue gas recycling + air preheating technology recycles 100% of the waste flue gas heat.

Key data highlights:

- 55% energy-saving than before

- 50% emission reduction than before

Reactor Automatic Temperature Control Technology

The reactor automatically adjusts the fuel mix ratio. This improves the automation level of continuous pyrolysis plant.

Key data highlights:

- ±10℃ precise temperature control

- Only 2 Operators Required

Plastic Pyrolysis Plant Projects Around the World

Features and Advantages of Beston Plastic Pyrolysis Plant

Multiple Security Design

Multiple Security Design

Plastic to fuel machine has multiple designs to ensure safety, such as temperature gauges, pressure indicators, explosion-proof valves, and the sealed feed system.

Eco-friendly Design

Eco-friendly Design

The waste emissions from this equipment meet the standards. Treated by environmental protection facilities, the combustion exhaust gas meets the emission standards. After treatment of a water cooling system, carbon black can be discharged. This can reduce dust pollution.

Integrated Control System

Integrated Control System

Beston’s plastic pyrolysis equipment can be equipped with PLC and DCS remote control systems. The system enables data storage and download functions. This can increase automation efficiency, save manpower and improve the working environment.

Long Service Life

Long Service Life

Our products are built with top-grade materials, crafted using expert welding techniques, and undergo rigorous quality inspections throughout production. This ensures a product lifespan of 5-8 years and offers excellent value for money.

Beston Group Customized Solution for Customers

Key Step 1: Project Needs Analysis

Firstly, we will thoroughly analyze customers’ project requirements. We will understand the production scale, funding budget, any specific requirements, etc.

Key Step 2: Project Scheme Design

- Recommend suitable machine: We offer a variety of specifications of equipment for you to choose from. Based on your project requirements, we will recommend suitable models of charcoal making machine for you.

- Optimize machine configuration: Depending on your specific requirements, we can upgrade the configuration. For example, if your location has strict environmental regulations, we can upgrade the dedusting and off-gas treatment system. This ensures an efficient and eco-friendly production process.

Key Step 3: Factory Production

Key Step 4: Installation and Other Post-sales Service

After the machines are produced, we provide installation services to ensure the equipment is properly set up and fully operational. Our technicians will assist with the installation process and ensure everything runs smoothly.

Additionally, our post-sales services include:

- Training: We provide comprehensive training to your team on how to operate and maintain the equipment.

- Maintenance & Support: We offer ongoing technical support and maintenance to ensure that your machines continue to perform optimally over the long term.

Sustainable Future Starts with Plastic Pyrolysis

Waste Reduction

Over 400 million tons of plastic are produced worldwide each year, with 1/3 of it being used only once. Pyrolysis extractly thermally decomposes plastics into oil.

- Reduce the volume of accumulated plastic waste

- Lessen the reliance on landfills and incineration facilities

- Improves environmental quality

Waste Resourcing

For professionals looking to upcycle discarded plastic resources, plastic to oil machine is a great choice. It transforms waste plastic into valuable pyrolysis oil, which can find versatile applications in various industries.

- Reduce dependence on finite fossil fuel resources

- Promote circle economy development

Contact Beston Group for Plastic Pyrolysis Solution

Beston Group has a proven track record of successful pyrolysis project installations worldwide. Through studies about the cases of oil sludge/plastic/tyre/rubber pyrolysis plant, you can gain insights into the performance and profitability of our pyrolysis solutions. If you have any inquiries, feel free to contact us! Follow us on YouTube/Facebook/Linkedin/Pinterest for regular updates.