Plastic to oil machines use pyrolysis technology to convert waste plastics (PE, PP, PS, etc.) into usable oil. This offers a sustainable alternative to landfilling. These machines are available in various scales, from small batch systems to large, continuous industrial plants. They can handle 6,000 tons annually or smaller sizes. This solution benefits both sustainable economic development and environmental preservation.

Plastic to Oil Process: Step by Step Guide

01 Feeding

Feed plastic waste into plastic pyrolysis reactor.

- BLL-30 (Continuous Type): Configured with screw feeder.

- BLJ-16 (Batch Type): Supports manual, hydraulic, or screw feeding.

02 Preheating

Start the main reactor rotation and preheating. Wait for the main furnace to reach the desired temperature. The fuel can be diesel, natural gas, heavy oil or pyrolysis oil. To save fuel consumption, we design syngas recycling.

03 Catalytic Pyrolysis

When the main reactor’s temperature reaches about 100℃ after 2-3h, it begins to produce oil gas. The high-temperature flue gas generated during pyrolysis is heated in the jacket layer of the catalytic tower, and the oil gas passes through the catalytic tower.

04 Condensing

Then high-temperature oil gas enters the vertical tube condenser, condenses into liquid oil, and enters the storage tank for storage. Non-condensable pyrolysis gas enters the water seal and is recycled for reactor heating. The excess pyrolysis gas enters the exhaust chamber for burning out.

05 Discharging

Close the burners after the reaction. The main reactor and the draft fan still operate normally. After 7-8h of natural cooling, the slag can be discharged by auto screw discharger and water-cooling discharger.

06 Flue Gas Dedusting

The high-temperature flue gas from the catalytic tower mixes the high-temperature flue gas from the main reactor then enters the flue condenser for cooling treatment, and enters the spray tower for spraying dust removal, then discharged through the chimney to the atmosphere.

Catalytic Pyrolysis: Core Technology Advantage of Plastic to Oil

Improve Oil Quality – ISCC Certify

Using catalysts significantly reduces the wax content in the oil produced during the plastic pyrolysis process, resulting in a higher-quality end product. This means the oil is purer and performs better, making it suitable for a wider range of industrial applications.

Improve 200% Production Efficiency

With the reduction of wax in the pyrolysis oil, the risk of pipeline blockages is greatly minimized. This directly reduces downtime due to cleaning and maintenance, significantly lowering maintenance costs and improving operational efficiency.

Improve Operation Safety

Wax accumulation causes pipeline blockages and leads to increased internal pressure within plastic pyrolysis equipment, posing safety risks. Catalytic dewaxing prevents this from occurring, ensuring stable and safe operation of plastic to oil machine.

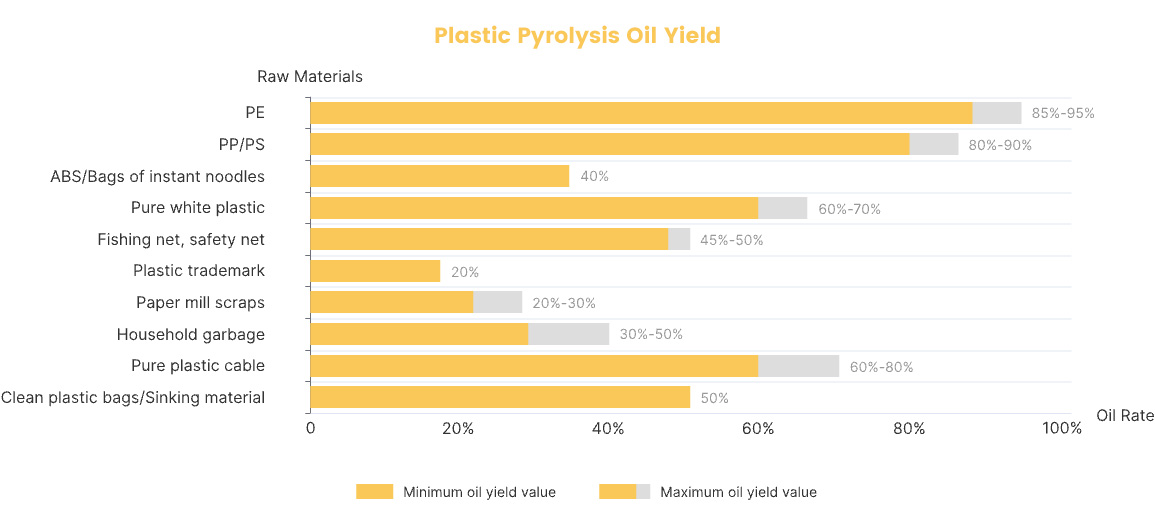

Plastic Types Analysis: Suitability for Pyrolysis and Oil Yield

| Types of Plastic | Applicability to Pyrolysis | Oil Yield (Lab Test) | |

|---|---|---|---|

| Polyethylene Terephthalate | × | low | |

| High-Density Polyethylene | √ | 80%-95% | |

| Polyvinyl Chloride | × | low and dangerous | |

| Low-Density Polyethylene | √ | 80%-95% | |

| Polypropylene | √ | 80%-90% | |

| Polystyrene | √ | 80%-90% | |

| Other Plastics without chlorine and oxygen | Plastics without chlorine and oxygen: √ Plastics with chlorine and oxygen: × |

/ |

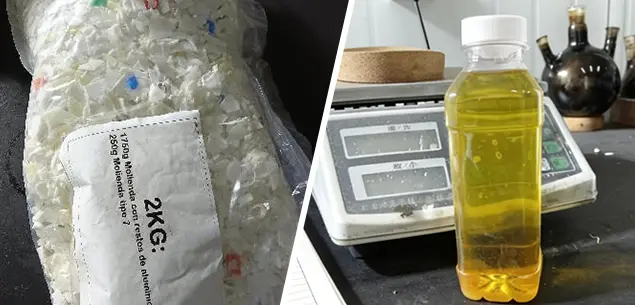

Laboratory Pyrolysis to Oil Test Reports

Between 2024 and 2025, different plastic samples were sent to Beston Group’s manufacturing base in Jiaozuo, China, for testing. In our laboratory, we conducted a series of experiments to determine the oil yield from various types of plastic waste, specifically focusing on HDPE, LDPE and PP. The pyrolysis reactions were performed under controlled conditions to simulate real-world applications, and the data collected is summarized below:

Data Interpretation and Analysis

The data suggests that HDPE provides the highest yield, with over 80% of the feedstock converted into oil. Polypropylene followed closely, with a yield of 75%, while polystyrene yielded the least, around 60%. The reason for these differences lies in the varying chemical bonds within the plastics, with HDPE and PP being more thermally stable and thus more readily converted into pyrolysis oil.

Expert Insights

Plastic pyrolysis is a rapidly developing field, and ongoing research continues to refine the conditions for optimal yield. These laboratory results align with existing studies in the field, which have shown similar yields for HDPE and PP under comparable conditions. By optimizing the pyrolysis process, it is possible to increase the yield further, improving the efficiency of plastic waste recycling.

3 Pyrolysis Oil Product to Get and Apply

Catalytic Pyrolysis Oil

Through catalytic pyrolysis technology, waxy and unstable components has been reduced in pyrolysis oil. Catalytic pyrolysis oil has such applications:

- Can be directly used as an industrial fuel

- Utilized for the production of chemical feedstocks, such as BTX

- Used as a refinery feedstock, undergoing hydrotreating for further upgrading and utilization

Naphtha

Naphtha is source from integrated pyrolysis + distillation technology and combustible gas-to-naphtha conversion technology. It has such applications:

- Used as a steam-cracking feedstock for the production of ethylene and propylene

- Applied in the chemical industry for the manufacture of plastics, synthetic rubber, and solvents

- Partially substitutes conventional fossil-based naphtha, supporting plastic circular economy initiatives

Non-Standard Diesel

Non-standard diesel is source from integrated pyrolysis + distillation technology. It has such applications:

- Used as fuel for industrial boilers, kilns, and heating systems

- Applied as fuel for self-use generators in mining areas and industrial plants

- Can be further upgraded to standard diesel through deep hydrotreating

Parameters of Plastic to Oil Machine for Sale

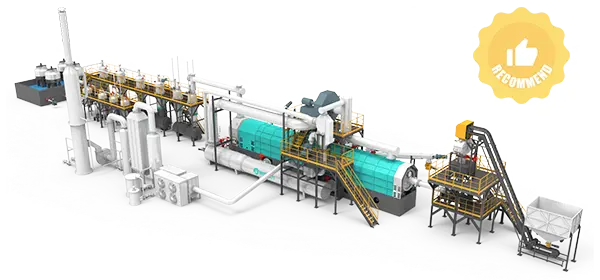

Continuous Type: BLL-30

- Large-scale pyrolysis plant choice: process 6,000 tons annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and project approval

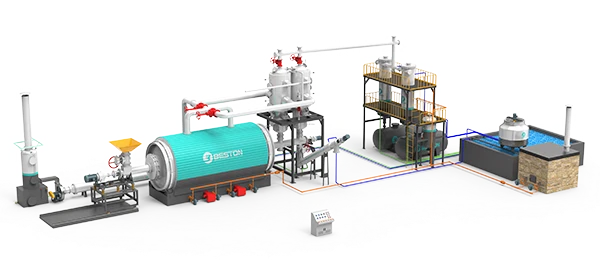

Batch Type: BLJ-16

- Small-scale choice: process 3,000 tons annually

- 1 furnace/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

Global Plastic to Oil Projects

BLL-30 Plastic to Oil Machine: Technical Breakthrough in Pyrolysis

One Step to Get Naphtha & Non-standard Diesel

Fractional distillation technology separates naphtha and non-standard diesel at a 200°C distillation point. Long-term benefits:

- Increase oil product purity and market value.

- Reduce operational costs (water, electricity, labor, and additional distillation investment).

Increase Processing Capacity by 50%

Large-capacity pyrolysis reactor (ø2800*10000) runs one batch per day, each recycling 15–16 tons of waste plastics. Long-term benefits:

- Greater scalability to larger-scale projects.

- Consistent supply of high-value oil products to meet market demand.

- Faster return on investment (ROI).

High Safety Factor

Thermal dynamic sealing and flexible high-temperature insulation technology enhance project safety. Long-term benefits:

- Lower risk of accidents.

- Ensure full compliance with safety regulations.

- Reduce downtime and maintenance costs.

- Strengthen corporate reputation and investor trust.

30 Days Non-stop Operation, 6000 T/Y Capacity

Advanced oil-gas condensation technology utilizes spray cooling to reduce temperatures rapidly. Long-term benefits:

- Meet industrial-scale plastic waste recycling demands.

- Reduce investment risk with higher production reliability.

- Deliver consistent oil output and predictable returns.

55% Energy-saving, 50% Emission Reduction

By recycling 100% of waste heat of hot flue gas, the BLL-30 continuous pyrolysis plant drastically improves energy efficiency. Long-term benefits:

- Obviously reduce fuel consumption and operational costs.

- Better comply with global environmental standards.

Automatic Temperature Control with ±10℃ Accuracy

The pyrolysis reactor allows self-adjustments to maintain optimal pyrolysis conditions within a ±10℃ range. Long-term benefits:

- High automation, requiring only 2 operators.

- Easy to operate, lowering skill requirements for workers.

- Stable pyrolysis conditions, bringing consistent oil quality and yield.

Unique Designs of Beston Plastic to Oil Machine

Floating Seal Technology

The main reactor combined floating sealing technology uses carbon fiber + high-temperature soft filler combined sealing. Compared with the traditional graphene packing sealing technology, it has good high-temperature resistance, corrosion resistance and wear resistance.

EU-standard Dedusting System

Combined with the higher exhaust gas treatment and wastewater discharge requirements of European clients, it can provide semi-dry or fully dry desulfurization, denitrification and de-dusting system to meet European emission standards.

Hot Air Heating System

Hot air heating method is safer, more uniform in heating, and more precise in temperature control. The most important thing is that waste heat can be recycled, energy saving and emission reduction can save 20-30 % of energy consumption.

Overpressure Alarm System

If overpressure occurs in the main furnace, the safety valve will automatically activate to relieve pressure. This can ensure the safety of both the equipment and personnel.

Torch Safety System

To address overpressure and storage risks from surplus pyrolysis gas and potential emergencies like power outages, a safe, highly automated torch system is installed as an emergency safeguard.

Nitrogen System

Nitrogen is introduced to reactor to replace air before ignition and slag discharge. It prevents flash explosions in the reactor and ensures safe and stable operation of the plastic to oil plant.

Why Plastic-to-Oil Makes Sense: A Comparative Outlook

Current plastic disposal and recycling methods remain limited in both scope and efficiency. Given that plastic bags are made from petroleum, they can be converted back into their original liquid oil form. In this context, plastic pyrolysis-to-oil solutions offer clear and compelling advantages.

Burning/Incineration

- Environment pollution: Burning waste plastics releases around 850 million metric tons of greenhouse gases annually and may emit harmful chemicals.

- Not achieve resource recycling: Burning waste plastics creates non-reusable ash while producing new plastic consumes 8-10% of the world’s petroleum.

Landfill or Leaked into Oceans

- Land/Ocean pollution: Landfill occupies large amounts of land and pollute the soil. Leaking into oceans pollutes oceans and endangers the survival of marine life.

- Slow natural degradation: It takes 20- 500 years or more for a plastic bag to degrade in a landfill. It can’t meet the increasing need for plastic disposal.

Mechanical Recycling

- Limited recycling times: Plastics are not infinitely mechanically recyclable (washing, grinding, pelletizing, etc.). Most plastics can only be recycled 3 to 7 times.

- Reduced plastic quality: Recycled plastics may not perform as well as new ones, impacting market demand and the feasibility of large-scale recycling.

Plastic Pyrolysis into Oil

- Better environmental compliance: Operates in low-oxygen conditions, minimizing toxic emissions like dioxins. Emission control systems further reduce environmental risks.

- Resource recovery: Recycle oil from plastic waste, saving non-renewable petroleum resources.

- High efficiency and scalability: Suit industrial application and solving the challenge of complex plastic waste streams.

How to Improve Plastic to Oil Yield?

Focus on Plastics Material Selection

Recommend PE, PP, PS, and more (please to oil yield chart). Avoid plastics with chlorine and oxygen content like PVC and PET, as they can pose hazards and have low oil yields.

Control Heating Temperature and Rate

To get a high oil yield, please use relatively lower high temperatures and a slow heating rate. To maximize gas yield, please keep the reactor at a relatively higher temperatures and a faster heating rate. Recommend intelligent control system.

Auxiliary Distillation Line

Implement a distillation line to further refine and separate the pyrolysis oil into various fractions, which can improve the quality and yield of the final oil product.

Regular Inspection and Cleaning of Equipment

Conduct regular maintenance and cleaning of pyrolysis equipment to prevent blockages and ensure the system operates at its optimal efficiency, thereby maximizing the oil yield.

Turning Plastic into Oil: A Step Towards Sustainable Development

SDG 12: Responsible Consumption and Production

Plastic-to-oil technology supports the goal of reducing waste by converting plastic waste into useful products instead of letting it accumulate in landfills or pollute the environment.

It contributes to sustainable production processes, as it promotes recycling and helps decrease the demand for virgin plastic production, reducing the environmental impact associated with plastic manufacturing.

SDG 13: Climate Action

By recycling plastic waste into oil, this technology helps reduce greenhouse gas emissions compared to traditional waste management methods such as incineration.

The technology can also lower the carbon footprint of plastic production by providing an alternative to petroleum-based products.

Additionally, the conversion process can reduce landfill methane emissions—a potent greenhouse gas produced by decomposing plastic.

SDG 7: Affordable and Clean Energy

Plastic-to-oil machines generate biocrude or synthetic oil, which can be refined into usable fuel or energy. This helps in diversifying energy sources and offers a more sustainable, clean alternative to fossil fuels.

This energy production can be more localized, potentially reducing the need for long-distance transportation of energy resources, leading to reduced carbon emissions.

Start Plastic-to-Oil Project Now

Beston Group has years of experience in researching and manufacturing plastic to oil machines, delivering reliable and efficient solutions worldwide. We look forward to partnering with forward-thinking leaders like you! More updates on Facebook/YouTube/Linkedin/Pinterest.