Sawdust charcoal making machine offers a sustainable solution for the wood processing industry. It converts wood waste (sawdust, shavings, wood chips, etc.) into high-value biochar. With an annual output of up to 6,000 tons of EBC-certified biochar, this sawdust charcoal machine paves the way for effective carbon removal projects. Please explore more details.

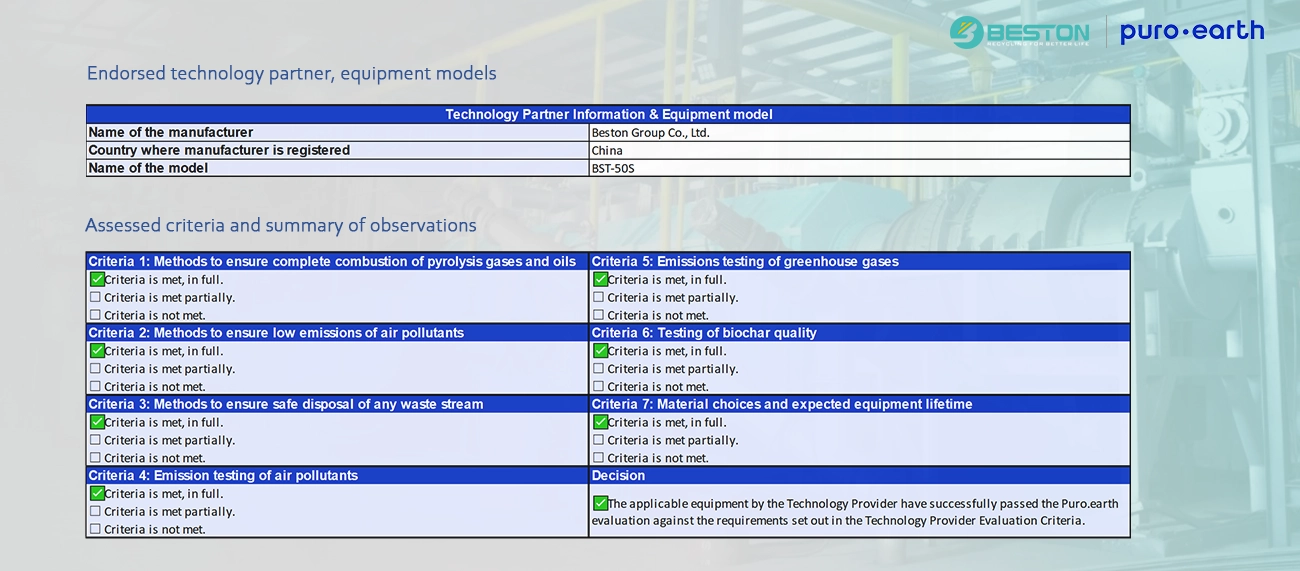

Sawdust Charcoal Machine Passes Puro.earth Evaluation

According to the Puro Standard Biochar carbon removal methodology (2022 Edition), Beston Group’s BST-50S sawdust biochar production equipment fully meets the certification requirements. Key features:

Technology Complies with CDR Criteria

The technology as a whole meets Puro.earth’s evaluation requirements for carbon dioxide removal (CDR) projects, qualifying it for carbon credit generation and trading.

Biochar Quality Meets EBC Standards

The resulting biochar offers long-term carbon sink stability (over 100 years). It is suitable for applications in agriculture, environmental restoration, and carbon credit markets.

Emissions Comply with EU Standards

Equipped with a high-efficiency gas treatment system, BST-50S achieves particulate matter, N₂O, and CH₄ emissions that are below regulatory limits.

Technical Breakthrough: 720 Hours of Continuous Operation

The BST-50S sawdust wood charcoal making machine has achieved a major milestone in pyrolysis system integration and design. This enables stable and continuous operation for up to 720 hours (30 days)—a leading performance in the industry. The following core technologies drive this breakthrough:

Sealed Combustion Chamber

Improved furnace structure and sealing design effectively reduce heat loss and prevent gas leakage, ensuring a stable reaction environment for long-term operation.

Fully Insulated Pipeline Design

Key pipelines are wrapped with multi-layer thermal insulation materials to prevent the condensation of tar and wood vinegar on pipe walls. This minimizes the risks of blockage.

Nitrogen Purging System

Nitrogen purging is applied at critical process points to prevent high-temperature dust accumulation and pipe blockage, thereby extending continuous runtime.

BST-50S Model: Maximizing Carbon Sequestration Potential

6000 Ton

biochar output per year

12000 Ton

CO2 locked per year

7200 Hour

operation time per year

> 10 m³

processing capacity per hour

Parameters of Sawdust Charcoal Making Machine

BST-50S Model

BST-06 Model

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Common Sources of Sawdust

Sawdust (or wood dust) is a by-product or waste product of woodworking operations such as sawing, sanding, milling and routing. It is composed of very small chips of wood. Here are some common sources of sawdust:

Sawmills

These facilities process logs into lumber, producing sawdust as a by-product during cutting and trimming operations.

Board Mills

Such factories produce products such as plywood and particleboard. A large amount of sawdust is generated during the molding process.

Furniture Manufacturers

This industry generates sawdust during the cutting, shaping, and finishing of wood to create furniture.

How to Make Charcoal from Sawdust?

01 Pretreatment

02 Feeding

03 Pyrolysis

- Drying Stage: From ignition until the reactor reaches 150°C, moisture in the sawdust evaporates, with little change in its chemical structure.

- Carbonization Stage: The reactor temperature rises to 160°C–450°C, causing sawdust decomposition, which transforms into charcoal.

04 Syngas Recycling

05 Cooling Discharging

06 Exhaust Gas Treatment

Applications of Sawdust Charcoal: Long-term Market Potential

Carbon Sink

Sawdust charcoal can locks carbon into the soil for extended periods, effectively reducing greenhouse gas concentrations in the atmosphere. This aspect aligns with global efforts to mitigate climate change.

Soil Conditioner

In agriculture, sawdust biochar added to soil can improve soil fertility by increasing nutrient retention and water-holding capacity. It also promotes healthy microbial activity in the soil, which contributes to better crop yields.

Building Materials

Sawdust charcoal is also utilized in the production of building materials. It can be incorporated into concrete and other construction materials to enhance their properties, such as thermal insulation and durability.

Metal Reductant

In metallurgy, sawdust charcoal serves as a reductant in the extraction of metals from ores. It provides a cost-effective and efficient solution for reducing metal oxides to their base forms.

Feed Additive

Sawdust charcoal can be used as an additive in animal feed. It helps to improve digestion and reduce gastrointestinal issues in livestock. Additionally, its absorptive properties can help in removing toxins from the animal’s system.

Fuel Alternative

Sawdust charcoal is an excellent alternative to traditional fossil fuels. It is an appealing option for use in domestic heating, BBQ, and industrial factories.

How Sawdust Charcoal Making Machine Bring Better Experience?

Security Designs – Safety Assurance

Multiple security designs ensure the safe operation of sawdust charcoal machine, such as explosion-proof devices, thermal linear expansion designs, multiple pressure and temperature sensors, etc.

Eco-friendly Design – Pollution-free Production

The cooling system and dedusting system can effectively recycle and reuse the water used for cooling and syngas. Additionally, the remaining flue gas is discharged after reaching the environmental protection standard after dedusting.

Durability – Quality Assurance

All the equipment is welded with national standard steel. Machining parts are all made of digital control materials. We strictly supervise the entire production process, including frame welding, CNC machining, equipment assembly, fine grinding and painting.

PLC Control – Convenient Manageability

PLC control monitors operating parameters and faults, reducing downtime and financial losses. Customers can set custom warning thresholds based on specific data attributes.

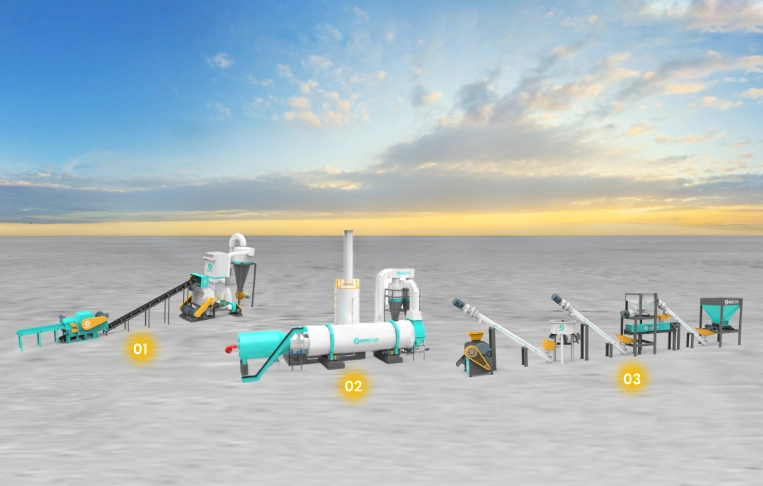

System Configuration of Sawdust Charcoal Making Machine

Core Biochar Pyrolysis Reactor

- Rotary Inner + Outer Cylinder Design: Ensures uniform graded carbonization of sawdust.

- Customizable Reactor Materials: Customers can choose from Q245R, SS304, or SS316 for enhanced durability.

- Indirect Heating System: Hot air heating minimizes direct contact with the reactor, reducing wear and extending its lifespan.

- Dynamic Sealing Technology: Achieves safer and more efficient operation.

Comprehensive All Components

The sawdust charcoal machine is composed of multiple integrated systems designed for efficiency:

- pretreatment system

- feeding system

- biochar pyrolysis reactor

- cooling system

- syngas recycling system

- dedusting system

- discharging system

Optional Auxiliary Equipment

Enhance your production with the following optional accessories:

- 01 Crusher: Breaks down sawdust into uniform particles, improving pyrolysis efficiency and energy efficiency.

- 02 Dryer: Reduces moisture content to optimal levels for smoother, more efficient carbonization.

- 03 Sawdust Charcoal Briquette Machine: Compresses the charcoal powder into uniform, dense briquettes for easier storage, transport and selling.

Worldwide Implementation of Sawdust Charcoal Making Machine

Sawdust into Charcoal Solution: ESG Investment Project

Environmental

- Reduce Sawdust Accumulation: Sawdust waste if not properly handled will occupy land, pose fire and occupational dust exposure risks, and pollute the environment. The sawdust carbonization project effectively reduces a large amount of sawdust.

- Lower Carbon Emissions: Sawdust incineration or landfill treatment produces large amounts of carbon dioxide and methane. Modern sawdust charcoal making machine uses efficient and clean production processes, meeting the urgent needs of today’s low-carbon economy.

- Protect Forest Resources: Converting sawdust into charcoal achieves resource reuse, reducing dependence on virgin wood.

Social

- Create Job Opportunities: Implementing a sawdust carbonization project, from raw material collection to carbonization production, product packaging, and sales stages, provides more jobs.

- Promote Local Economic: The operation of a sawdust carbonization project will introduce more investment and technology or the local. It also promotes the growth of related industries such as agriculture and manufacturing.

- Enhance Environmental Awareness: Sawdust carbonization project can serve as a model to demonstrate the importance and feasibility of waste resource utilization, encouraging more environmental protection initiatives.

Governance

- Enhance Corporate Image and Reputation: By fulfilling environmental and social responsibilities during the sawdust carbonization project, companies can improve their image and reputation, increase brand value, and gain more trust from customers and investors.

- Assist Clients in Project Operations: During its project advancement, a successful project helps refine the investor company’s management and operational mechanisms. As an experienced solutions and equipment provider, Beston Group assists clients in assessing operational qualifications, developing project operations teams, and driving project success

Beston Group Is Trustworthy – Perfect Service System

Pre-Sale Services

- Rapid response to any inquiry.

- Provide detailed technical information.

- Offer the option for customers to visit the factory.

- Offer the option for customers to test raw materials.

- Suggestions on reasonable shipping freight.

- etc.

After-Sale Services

- Follow the manufacturing department with high quality.

- Professional inspection department guarantees quality.

- Help to finish the certificate and profit report.

- Fast delivery helps keep track of goods till buyers receive the goods.

- Engineers will go to clients’ sites for the installation, test-running, and free training.

- etc.

Tailor Sawdust Management Plan to Your Needs

Beston Group’s sawdust charcoal making machine offers solution for the resource utilization of wood processing by-products. It paves the way for sustainable transformation in the wood industry. Want to turn sawdust into profit? Explore pyrolysis recycling solutions with us. Welcome to visit our LinkedIn!