Tyre pyrolysis plant converts scrap tires into valuable products: pyrolysis oil, carbon black, and steel wire. It offers both an effective waste solution and profitable returns. As the tire waste problem worsens, more customers are seeking sustainable and profitable solutions. Let Beston Group guide you in exploring the advantages of tire pyrolysis.

Tire Pyrolysis Plant: 100% Recycling Solution

Every year, 1.5 billion non-biodegradable waste tires threaten the ecological environment. Tyre pyrolysis machine provides a sustainable solution for resource utilization and waste reduction. Waste tire can be transformed into four high-value products:

Pyrolysis Oil (40% – 45% Yield)

By using Beston tyre pyrolysis plants, different types of oil can be obtained, including common tyre pyrolysis oil, naphtha, and non-standard diesel. These oils have broad economic value and applications across multiple industries:

- As industrial fuel;

- As chemical feedstock for further processing;

- Be refined into commercial gasoline and diesel with proper upgrading.

Carbon Black (30% – 35% Yield)

Carbon black derived from tyre pyrolysis can be utilized in several profitable ways:

- Manufactured into carbon bricks for construction use;

- Applied in the production of rubber, plastics, inks, and coatings;

- Through grinding and pelletizing processes, it can be upgraded into high-quality carbon black grades such as N550 and N660, increasing the product’s value by up to five times.

Steel Wire (15% – 20% Yield)

Steel wire can be sold to steel mills or recycling companies, where to be reused in tire production or reprocessed into other metal products.

Combustible Gas (5% -7% Yield)

The combustible gas generated during the pyrolysis process mainly fuels the pyrolysis reactor itself, thus no need for additional energy.

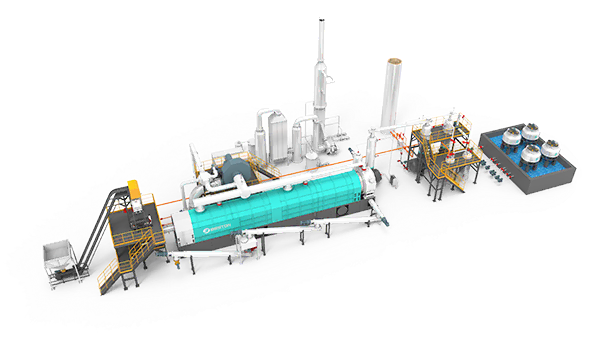

Choose Suitable Tyre Pyrolysis Plant to Start Projects

BLL-30 Model Recommend

- Process 10,000 tons of tyres annually

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get project approval

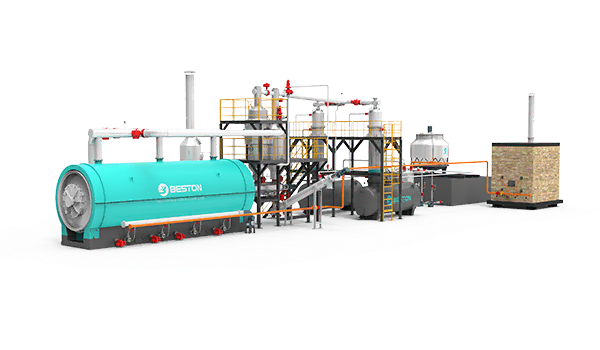

Batch Type: BLJ-20 Newly launched

- Process 6,000 tons of tyres annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 4,000 tons of tyres annually

- 1 batch/day

- 2 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 60 |

Technology Breakthrough of BLJ-20 Tyre Pyrolysis Plant

Fraction Distillation Technology

Tire pyrolysis process can also realize fraction cutting function, realize oil classification and quality collection, and obtain naphtha and non-standard diesel respectively.

- Energy saving & consumption reduction: Reduce heating and cooling loads.

- Product optimization: High light component yield and sufficient heavy component recovery.

- Investment optimization: Reduce intermediate equipment, resulting in lower floor space and capital expenditures.

ø2800×10000 Large Pyrolysis Reactor

The reactor design improves processing capacity from 12-15 tons/day to 18-20 tons/day.

- Larger processing scale: Annual tire treatment capacity up to 6,000 tons, ideal for medium to large projects.

- Better Economic Return: Improved equipment utilization and generated more revenue from oil products.

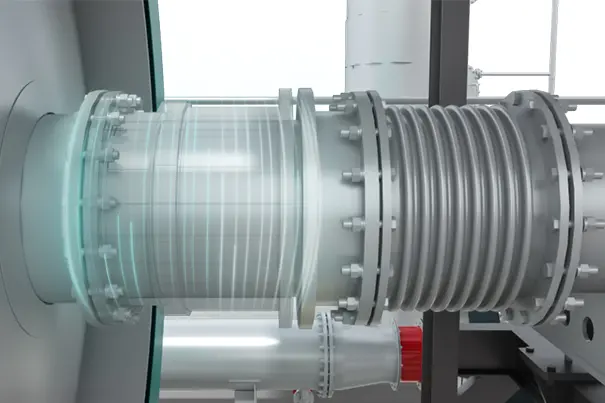

Thermal Dynamic Sealing + Flexible High-temperature Insulation Technologies

These dual technologies enhance reactor sealing and insulation, ensuring safer, more reliable operation. The benefits include:

- Leakage Prevention: Improved sealing prevents the escape of oil and gas.

- Flameless Environment: Eliminates the risk of fire by keeping the site free of open flames.

- Reduced Heat Hazards: Advanced insulation blocks heat radiation, safeguarding operators.

Technology Breakthrough of BLL-30 Tyre Pyrolysis Plant

Advanced Oil‑Gas Condensation Technology

This technology rapidly reduces the temperature of oil gas, effectively preventing olefin polymerization and blockage in the pipelines. Thus, tyre pyrolysis machine achieves 30 days non-stop running, creating the following value:

- Maximized Annual Capacity: With minimal downtime, a single BLL-30 unit handles 10,000 tons of waste tyres into oil annually.

- Higher ROI: Stable oil yields and reduced maintenance costs will bring consistent, long-term profitability.

Hot Flue Gas Recycling & Air Preheating Technology

This technology recycles 80% of flue gas to heat pyrolysis reactor and the other 20% to preheat fresh combustion air. It achieves:

- Lower Fuel Costs: Reduce fuel consumption by 55%, cutting overall operating expenses.

- Easier Eco-compliance: Lower exhaust emissions by 50%, making it easier to meet regulatory emission standards.

- Reduced Investment in Gas Treatment: Reduce the need for expensive exhaust treatment equipment, lowering capital costs.

Reactor Automatic Temperature Control Technology

By automatically adjusting the fuel mix to varying fuel properties, this technology maintains optimal reactor temperature with ±10 °C precision. Key benefits include:

- Ultra-Easy Operation: No need for constant monitoring or manual temperature adjustments.

- Reduced Labor Costs: Only 2 operators are needed, cutting labor requirements by 80%.

- Improved Output Quality: Stable temperatures ensure higher oil yield and better rCB quality.

Global Cases of Tyre Pyrolysis Plants

Tyre pyrolysis plants (also tyre oil plant) have been successfully implemented worldwide, enabling businesses to achieve both environmental and financial goals. Beston Group has dedicated years to researching, developing, and manufacturing innovative tyre pyrolysis plants. Case studies demonstrate how we leverage pyrolysis technology to foster extensive cooperation and enhance sustainability. Interested in learning more? Just contact us!

Tire Pyrolysis Superiority: Compares to Other Treatment Methods

| Technology | Usage & Features | Secondary Pollutants | Facility Investment | Energy Consumption | Limitations |

|---|---|---|---|---|---|

| Landfill | Traditional method, but increasingly prohibited | Soil and water pollution | Low | Low | Gradually being restricted globally |

| Retreading | Suitable for slightly worn tires that have not reached the end of their life | / | Low | Low | Limited processing capacity |

| Incineration | Suitable for tires that cannot be reused | Air pollution | High | High | High environmental control costs |

| Shredding | Suitable for non-retreadable tires, can be processed into rubber granules, etc. | / | High | High | Limited market demand for recycled products; difficult to handle large volumes |

| Tire-Derived Fuel | Uses tires’ high calorific value in power plants, industrial boilers, cement kilns | Secondary solid (ash) and air (SO2, NOx, dioxins) pollutants | Very High | High | High pollution control costs |

| Pyrolysis | Suitable for all types of tires, produces fuel oil, carbon black, and other byproducts | High-end dedusting treatment avoid pollution | Moderate | Low | / |

Knowing Tyre Pyrolysis Plant Working Principle

01 Pretreatment

If the tire pyrolysis machine is equipped with a tire shredder, it first breaks down the tires into smaller chunks that meet the required feeding specifications.

02 Feeding

03 Pyrolysis

04 Condensation

05 Dedusting

06 Residue discharging

Pyrolysis Raw Material Options and Output Distribution Analysis

Various scrap tires and industrial rubber waste are ideal candidates for pyrolysis recycling. Generally, the purer the rubber, the higher the oil yield. At our specialized laboratory, we can conduct tests to assess whether your rubber raw materials suit pyrolysis. Welcome contact us to get your rubber materials tested.

| Raw Material | Details | Fuel Oil | Steel Wire | Carbon Black | Combustible Gas |

|---|---|---|---|---|---|

| Tires | Truck Tires | 45%-50% | 15%-20% | 30% | 5%-10% |

| Car Tires | 40%-45% | 10%-15% | 40% | 5%-10% | |

| Bicycle/motorcycle Tires | 30%-35% | 5%-10% | 10% | 5%-10% | |

| Rubber | Rubber Cable | 25%-35% | |||

| Shoes Sole | 25%-35% | ||||

| Mixed Sole | 20%-30% | ||||

| Sneakers | 20%-30% | ||||

| Waste Fiber Carpet | 30% | ||||

| PMMA | 40% |

Advanced Technologies Optimize Your Tyre Pyrolysis Business

Safety Assurance

- Nitrogen System: Nitrogen is introduced for replacement before ignition and slag discharge. This can prevent flash explosions in the pyrolysis reactor and ensure safe and stable operation of the equipment.

- Overpressure Alarm System: In the event of overpressure in the main furnace, the safety valve will be automatically opened for emergency pressure relief to ensure equipment safety and personal safety.

- Floating Seal Technology: Achieve reactor’s dynamic sealing with carbon fiber and high-temperature soft filler. More resistant to high temperatures, corrosion, and wear.

- Each semi continuous pyrolysis equipment is equipped with multiple temperature, pressure, and liquid level observation points.

Energy Saving

- Syngas Recycling System: The combustible gases produced during the pyrolysis process are recycled as fuel for the pyrolysis furnace, ensuring thermal energy supply and reducing exhaust emissions.

- Insulated Reactor Casing: Minimizes heat loss during heating, thus decreasing fuel consumption.

- Hot Air Heating Technology: Achieve more uniform heating and more precise temperature control.

Efficient Operation

- Anti-Coking Technology: Minimizes coking and residue build-up, lowers maintenance frequency and reduces the overall maintenance costs.

- Continuous Pyrolysis Technology: Enables uninterrupted feeding and discharging, eliminating the need for machine cooling during operation, thus enhancing the system’s efficiency and uptime.

Eco-friendly production

- Customized Dedusting System: meet EU emission standard or your local standard.

- Enclosed feeding and discharging system: reduce dust pollution.

- The cooling water is recycled multiple times, which saves resources.

Intelligent Control

- PLC and DCS Remote Control: Improves control efficiency, reduces manpower requirements, and improves the working environment.

- IoT Technology: Enables real-time online monitoring and intelligent data transmission. Enhance operational convenience and safety.

Auxiliary Configuration Further Convient Your Business

Tyre Wire Drawing Machine

The main function of the machine is to extract steel wire from waste tires. Scrap tires often contain steel wire curtains and wire edges that require separation and extraction for subsequent processing and recycling.

Tyre Rubber Powder Making Machine

Continuous pyrolysis plant requires strict feed size specifications. This machine refines the cut rubber particles into rubber powder, ensuring the size and quality meet specific standards.

Oil Distillation Equipment

This machine distills and separates the original pyrolysis oil. After the process, it transforms pyrolysis oil into high-quality non-standard diesel, enhancing the economic value of the final product.

Feasibility Report of Tyre Prrolysis Plant Investment

Market Analysis

- Humans currently produce more than million metric tons of tyre waste every year. It brings us pollution and damage, affecting the environment and people’s health heavily. So it is necessary to take measures to recycle tyres.

- Tyre recycling is gaining momentum globally due to increased environmental awareness and regulatory measures.

- The demand for alternative fuel is rising, driven by concerns over rising petrochemical energy costs, resource conservation, and sustainable development.

Technical Feasibility

- Beston Group’s catalytic pyrolysis technology ensures efficient conversion of waste tyres to fuel oil. Its pyrolysis machine is ISO and CE certified, safe and environmentally friendly.

- Beston Group has developed various models for tyre recycling machine for small-scale recycling operations. Also, there is larger continuous pyrolysis plant available. Moreover, customization options to meet specific customer requirements.

Investment Feasibility

- Factory Area: The tyre pyrolysis plant requires relatively small factory space, making it suitable for locations with limited available land. Our professional technicians can accurately calculate the required area based on specific project requirements.

- Investment Fund: Small recycling projects have lower initial investment requirements compared to large plants, providing a cost-effective entry point for the tyre recycling industry.

Financial Projections

- By converting waste tyre into valuable fuel oil, tyre pyrolysis machine has significant revenue-generating potential. Economic profits of that are expected.

- Beston Group can offer detailed financial projections that will consider factors such as initial investment, operational expenses, and revenue streams.

Environmental Impact

- Tyre pyrolysis recycling project helps mitigate environmental pollution. It also reduces reliance on non-renewable materials, conserving natural resources. So project approval may be relatively easier.

Why Focus on the Waste Tyre Disposal Issue?

Each year, approximately 1 billion scrap tires, weighing around 17 million tonnes, are generated worldwide. However, only 40% of these tires are recycled. And given the following factors, more and more investors are seeking viable tire waste recycling solutions.

Non-biodegradable and Environmental pollution

Waste tires are difficult to decompose, potentially taking decades or centuries. Their persistence can lead to soil and water pollution and release terrible smells, negatively impacting ecosystems.

Bulk and disposal challenges

Waste tires are bulky and take up a lot of space, making disposal a significant challenge. Often, they are simply stacked in open areas, resulting in land use problems and unsightly litter.

Resource value

Waste tires are primarily made from synthetic rubber and carbon black. Therefore, despite being difficult to degrade, they can be processed and repurposed into other products, such as rubber powder, fuel, or construction materials.

Fire hazard

Tyre flammability poses a safety hazard. Once ignited, they are difficult to extinguish, producing large amounts of harmful smoke. This post safety risks to nearby regions.

Beston Group – Your Partner

Pre-Sales Support

- Free professional product technical consultation

- Material testing with a specialized bilingual test report provided

- Customized technical solutions based on customer requirements

In-Sales Support

- Free equipment layout design based on the customer’s site conditions

- Real-time updates on product manufacturing and delivery status

- Accept customers to the factory to verify the goods before delivery;

Post-Sales Support

Large-scale Manufacturing Factory

- 20,000 ㎡ factory area and an office space of 2,401 ㎡

- Quick manufacturing capabilities and fast delivery times

- Factory-direct pricing helps you save on your budget

Start Your Tyre Pyrolysis Project with Beston Group

Start your tyre pyrolysis project with Beston Group today and turn waste into profit while reducing tyre pollution. With our cutting-edge technology and full-service support, we ensure your project’s success from start to finish. Ready to learn more? Visit Facebook/YouTube/Linkedin/Pinterest for detailed information and expert guidance.