Tyre to oil plant, as a vital force in the modern circular economy, is redefining the value of waste tires. Using advanced high-temperature, oxygen-free pyrolysis technology, waste tires are converted into high-value products: pyrolysis oil, carbon black, steel wire, and combustible gas. This process maximizes resource utilization and supports both economic growth and environmental protection. It drives waste management toward a greener and more sustainable future.

2 Core Innovative Technologies of Beston Group’s Tire to Oil Plant

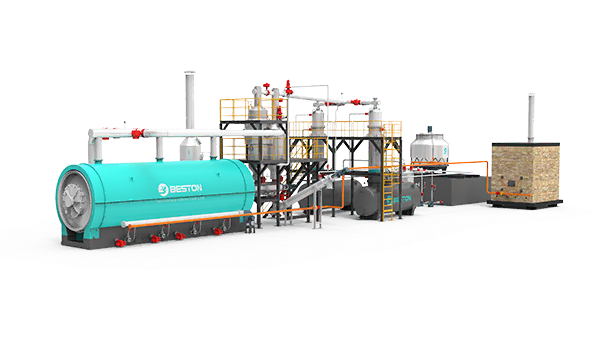

Pyrolysis-Distillation Integrated Technology (Applicable to BLJ-20 Model)

BLJ-20 tyre to oil machine integrates tire pyrolysis and oil refining into one system. This enables a one-step process to produce high-quality oil.

- Upgrade Oil Quality: Produce higher-grade, more versatile naphtha and non-standard diesel with greater market value.

- Enhance Efficiency: No need for secondary processing steps, and shorten the overall production cycle.

- Reduce Investment Cost: No need for additional distillation equipment, while also lowering energy consumption and labor costs.

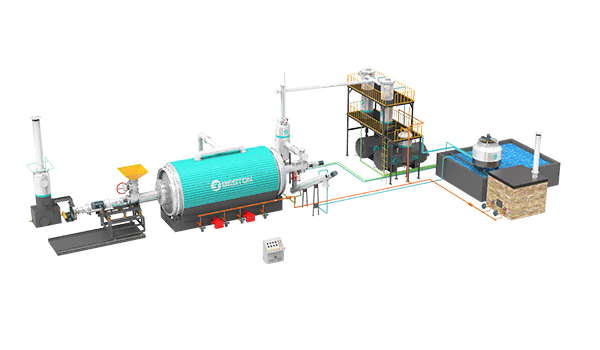

30-Day Continuous Pyrolysis Technology (Applicable to BLL-30 Model)

BLL-30 tire to oil plant features automated feeding/discharging and efficient oil-gas condensation, enabling 30 days of non-stop operation.

- Lower Operating Costs: Minimize downtime for cleaning and reheating, reducing energy waste and labor input.

- Industrial-Scale Production: Ideal for commercial tire-to-oil facilities and large waste tire processing centers, delivering a higher ROI.

- High Oil Yield: Optimized heating curves and material distribution ensure maximum conversion of tires into oil and carbon black.

Parameters of Tyre to Oil Plant for Sale

BLL-30 Model Recommend

- Process 10,000 tons tire waste annually

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get project approval

Batch Type: BLJ-20

- Process 6,000 tons tire waste annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 4,000 tons tire waste annually

- 1 furnace/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 60 |

South Africa Case Study: A Successful Commercial Tire to Oil Project

The client is a metal and waste recycling company. Their new operational goals are to process large volumes of non-recyclable waste and reduce fuel costs at their smelting facilities. To achieve this, they have adopted a pyrolysis solution.

Project Overview

- Raw Materials: waste tires and plastics

- Pyrolysis Oil Use: Fuel for aluminum melting furnaces and old trucks

- Configuration: 2 × BLJ-16 (Q345R) tyre pyrolysis plant + 1 × BZJ-10 distillation system

- Processing Capacity: 10–12 tons of tires per batch and 8–10 tons of plastics per batch

Project Execution

Tyre to oil plant has been successfully installed, commissioned, and is now fully operational.

- Project Start Date: June 7, 2023

- Project Operation Date: February 26, 2025

- Project Acceptance Date: March 12, 2025

- Total Project Duration: 631 days

Classification and Applications of Oil from Waste Tires

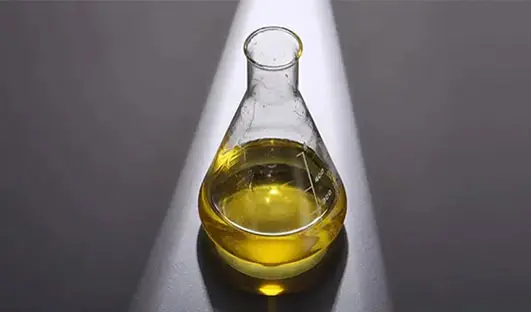

Tire Pyrolysis Oil

Characteristics: High calorific value; mainly light and middle hydrocarbons.

Applications:

- Industrial heating fuel

- Can be further refined into diesel or gasoline

Naphtha

Characteristics: Low-boiling, light hydrocarbons separated from tire pyrolysis oil.

Applications:

- Basic chemicals production (e.g., ethylene)

- Used in paints, coatings, and industrial solvents

- Blending component for gasoline

- Kerosene, jet, and other fuels production

- Laboratory solvent

Non-Standard Diesel

Characteristics: Middle-distillate hydrocarbons heavier than naphtha, derived from pyrolysis oil.

Applications:

- Industrial heating fuel

- Fuel for diesel generators

- Other scenarios with relatively flexible emission requirements

Yield of Tyre to Oil Plant for Reference

| Raw material | Details | Oil Yield | Steel Wire | Carbon Black | Gas/Water |

|---|---|---|---|---|---|

| Waste tire | Truck tires | 45%-50% | 15%-20% | 30% | 5%-10% |

| Car tires | 40%-45% | 10%-15% | 40% | 5%-10% | |

| Bicycle/motorcycle tires | 30%-35% | 5%-10% | 10% | 5%-10% |

ISCC Certification for Tire Oil – Beston Group’s Technical Safeguards Ensure Sustainable Compliance

At Beston Group’s tire to oil plants, production follows strict technical standards. All pyrolysis data (e.g., emissions) is fully traceable, supporting ISCC sustainability compliance and providing strong technical backing for certification. Manufacturers can apply for ISCC Plus and EU certification for tire pyrolysis oil.

Note: Pyrolysis oil manufacturers remain responsible for feedstock and other compliance aspects.

ISCC EU

- Applicable for biofuels or renewable energy in the European market.

- Emphasizes compliance with EU regulations, including the Renewable Energy Directive (RED II).

ISCC PLUS

- Applicable for non-fuel uses or uses outside the European market.

- Can be used in chemicals, materials, industrial applications, and fuel (only outside the European market).

How to Convert Waste Tyre into Oil? – Working Principle

01 Pre-treatment

Pre-treatment involves tire shredding and wire removal.

- For a batch tyre to oil plant, wire removal is not required, but the tire size must meet the feed requirements. Steel wires are collected after pyrolysis.

- For a continuous tire to oil plant, shredding and wire removal are required. Steel wires are collected at this stage.

02 Feeding

03 Pyrolysis

04 Oil Gas Condensation

- High-temperature oil gas passes through the condensation system and is cooled into liquid pyrolysis oil.

- Non-condensable gases are purified and recycled to provide heat for the pyrolysis process.

05 Carbon Black Discharge

06 Safety & Environmental Emission Control

How Beston Tyre to Oil Plant Achieves Optimal Oil Production?

Rotary Reactor Structure

Low-speed rotary reactor (0–0.34 rpm) allows continuous tumbling of the material during pyrolysis, which:

- Enhances heat transfer between the material and reactor walls

- Effectively reduces adhesion and coking

- Increases pyrolysis efficiency and oil yield

High-Efficiency Condensation Technology

The vertical tubular condenser provides a large heat-exchange area and high condensation efficiency, enabling the system to:

- Cool pyrolysis vapors rapidly

- Prevent secondary polymerization of olefin compounds

- Stabilize and increase oil recovery

Development of Continuous Pyrolysis Technology

Compared with batch tire to oil plant, continuous pyrolysis plant enables more stable oil production in large-scale operations while improving equipment utilization and overall production efficiency.

PLC & DCS Intelligent Control

The PLC or DCS system continuously monitors key process parameters, records operational data, and supports remote monitoring. This helps to stabilize pyrolysis conditions and enhance operational reliability.

Tire Pretreatment Solution Option

Customize a complete pre-processing line according to customer requirements, including shredding, cutting, and wire-removal stages, to process tires to the optimal particle size, which:

- Enhances uniform heating of the material

- Improves pyrolysis efficiency and oil yield

Flexible Oil Distillation Solutions

Two distillation options are available to suit different market needs.

- Option 1 – Integrated BLJ-20 pyrolysis + distillation solution: directly produce higher-value naphtha or non-standard diesel.

- Option 2 – Independent Distillation Line: separates different fractions, suitable for clients with strict or diverse oil product specifications.

EPC Services: Realize Your Tyre-to-Oil Project

EPC services are an Engineering, Procurement, and Construction turnkey solution. Beston Group manages the entire project—from design and equipment procurement to construction and commissioning—ensuring quality, safety, cost control, and timely delivery.

EPC Service Field

- Industrial park planning and design

- Steel structure workshop construction

- Installation and commissioning of tire to oil plant

- Park roads, water supply and drainage works

- Supporting facilities such as office buildings and dormitories

EPC Service Advantage

- Accelerate Project Delivery: Streamlined execution accelerates project completion. Simplifies project management and accountability.

- Custom Solution: EPC teams can design plants based on feedstock availability, output requirements, and local regulations.

- Reduce risk: Professional oversight minimizes delays, technical issues, and budget overruns.

Learn More about Tyre to Oil Plant Cases

Start Tyre to Oil Recycling Project Now

Turn your waste tyres into valuable fuel with Beston tyre to oil plant. Reduce environmental impact, boost profits, and join the sustainable energy movement now! More updates on Facebook/YouTube/Linkedin/Pinterest.