Wood charcoal making machine gains increasing popularity as a sustainable solution for wood waste reduction and resource recovery. Ultilizing continuous pyrolysis technology and passing Puro.earth evaluation, Beston wood to charcoal machine supports producing EBC-grade biochar and brings more potential in carbon removal. Welcome your inquiries.

Wood Charcoal Machine: Puro.earth-Vetted Continuous Pyrolysis Solution

Beston wood coal making machine (also biochar machine) stands out due to its groundbreaking 720-hour continuous operation technology. This innovative technology maximizes carbon removal potential, contributing significantly to sustainable development. Explore the key innovations and benefits:

Pass Puro.earth Evaluation

Pass Puro.earth Evaluation

Continuous operation time enables the machine and its production process to meet the Puro.earth standards. The Puro standards focus on sustainability and carbon reduction. Investors with this machine can:

- establish biochar production project that meets EU environmental protection standards.

- produce biochar certified to EBC standards.

- gain access to the carbon trading market and generate profits.

Extend Continuous Operation Time to 720 Hours

Extend Continuous Operation Time to 720 Hours

From 120 hours to 720 hours breakthrough, Beston Group extends the continuous operation within four months. This breakthrough has such benefits:

- addresses critical challenges in biomass pyrolysis: (1)Liquefaction of tar and wood vinegar; (2) carbon powder buildup in pipelines.

- reduce machine’s downtime and maintenance costs, significantly enhancing pyrolysis production efficiency.

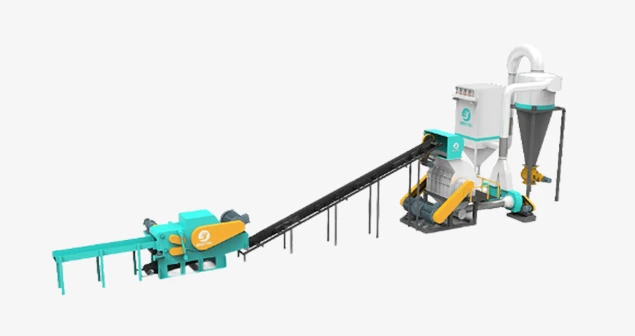

Models of Wood Charcoal Making Machine for Sale

Beston Group offers different models of wood charcoal manufacturing machine. Additionally, there are various optional configurations for feeders, dedusting system, auxiliary equipment, and more. Share your requirements, and Beston Group will offer you customized solutions.

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

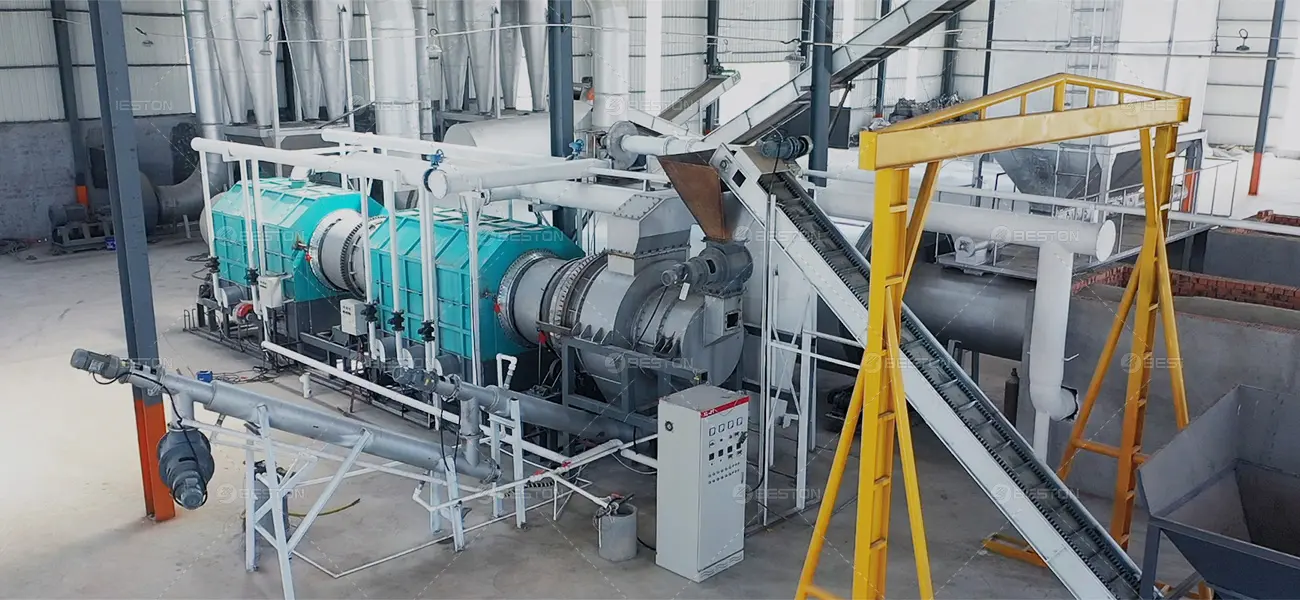

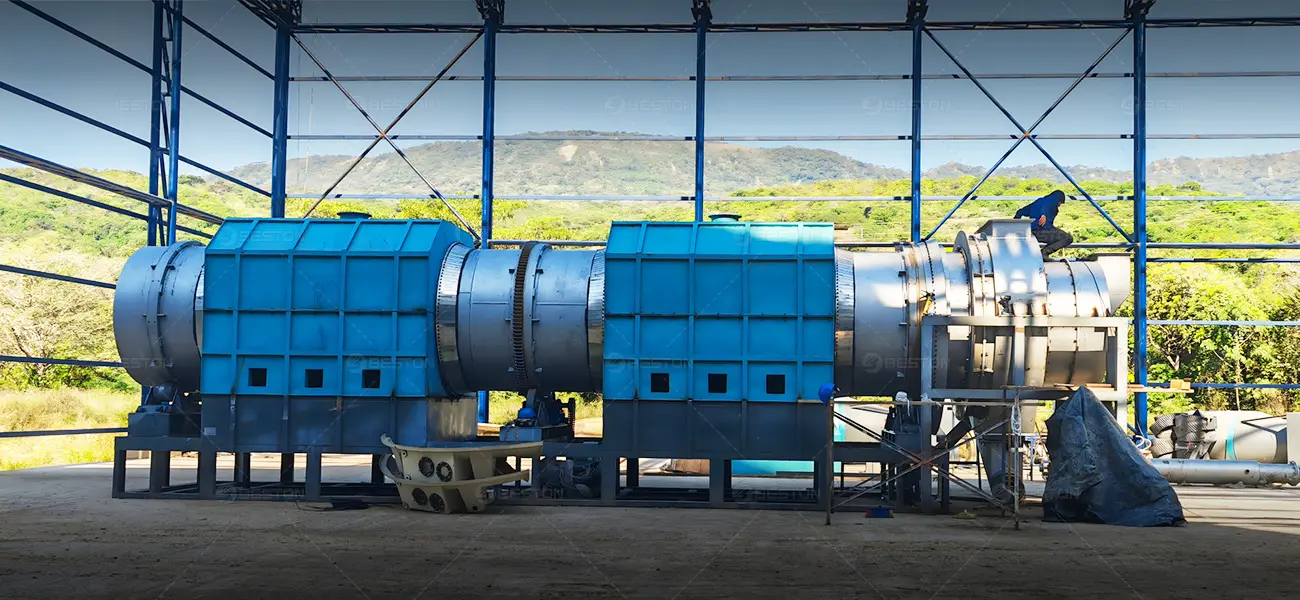

Display of Wood Coal Making Machine

Global Cooperation in Wood-to-Biochar Project Cases

Wood Charcoal Making Machine in Finland

Project Time: from 2023;

Processing Capacity: 2-4m³/h;

Raw Material: wood chips;

Wood Charcoal Use: BBQ charcoal.

Wood Charcoal Machine in Spain

Project Time: from 2023;

Processing Capacity: 10-15m³/h;

Raw Materials: olive wood;

Wood Charcoal Use: carbon credits trading.

Wood Pyrolysis Plant Installed in Malaysia

Project Time: from 2023;

Processing Capacity: 7-9m³/h;

Raw Materials: wood waste.

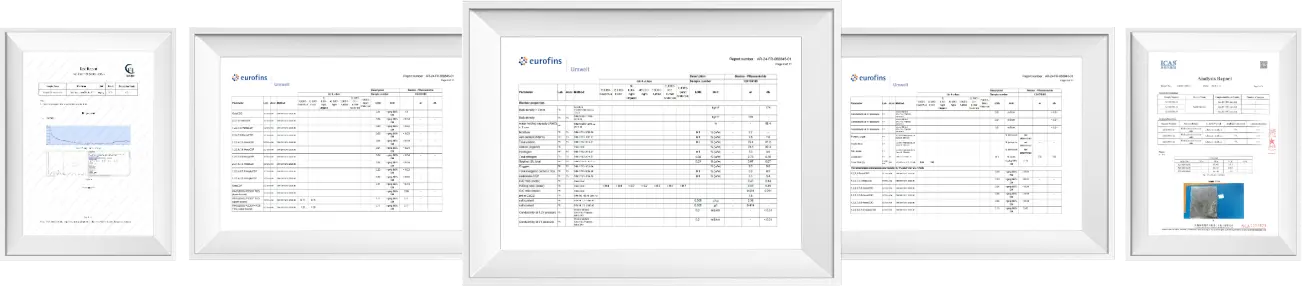

Get Biochar Meeting EBC Standard from Wood Charcoal Machine

Beston Group has submitted wood biochar samples to internationally recognized third-party laboratories. The results show the biochar from biomass pyrolysis plant meets the European Biochar Certificate (EBC) standards in key indicators, including H/C molar ratio, PAHs content, and heavy metal levels. This ensures its suitability for applications in agricultural soil improvement and carbon sequestration projects across Europe and beyond.

| Load capacity | EBC Standard | German Laboratory | Chinese Laboratory |

|---|---|---|---|

| H/C Molar Ratio | <0.4 – 0.7 | 0.45 (Generally Meets All Application Standards) | 0.11 – 0.32 |

| Heavy Metal | Depends on Specific Application | Fully Meet All | Fully Meet All |

| PAHS-8 | Depends on Specific Application | Fully Meet All | / |

| PAHS-16 | <6 mg/kg | Compliant with EBC-Feed, Urban, Basic Material Slightly above EBC Feed-Plus, Agro-Bio, Agro | 0.2 mg/kg |

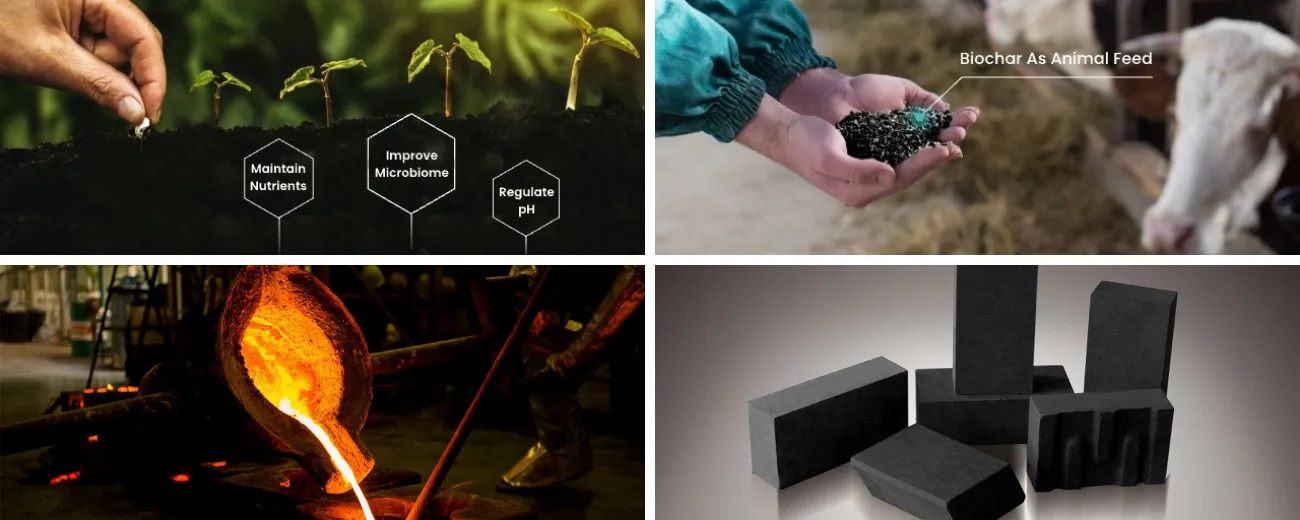

Key Applications of Wood Biochar: in Carbon Removal and Fuel Fields

I. Carbon Removal Field

Soil Improvement: Decarbonization in Agriculture

By incorporating biochar produced by wood charcoal making machine into the soil, it can:

- store carbon stably in soil; generates carbon credits that can be traded

- improve soil structure and nutrient content

Specific Application Scope: Farms, plantations, and forestry areas.

Biochar Animal Feed: Decarbonization of Animal Husbandry

Research has shown that adding biochar to animal feed can reduce methane emissions from cattle stomachs by 10% to 20%. Biochar works in the following ways:

- optimize the digestive process of ruminants, thereby reducing methane production in the gastrointestinal tract.

- adsorb and remove harmful substances from the feed, improving animal health.

Building Material: Decarbonization of Construction

Wood-based biochar is increasingly being used in the construction industry as part of carbon-negative building materials. Its use in sustainable construction provides multiple advantages:

- Biochar’s ability to store carbon for long periods helps reduce the overall carbon footprint of construction materials.

- By incorporating biochar, building materials can become more environmentally friendly, contributing to a more sustainable construction sector.

Act as reducing agent: Decarbonization of Metal Smelting

Biochar also plays a key role in the metal smelting industry by acting as a reducing agent in the extraction of metals. Here’s how it works:

- Biochar, particularly charcoal derived from it, has a high carbon content. It captures oxygen molecules from metal ores, helping to reduce metal oxides into pure metals in the smelting process.

- By replacing fossil fuels traditionally used in metal smelting, biochar helps lower the carbon emissions associated with metal production, contributing to decarbonization of this energy-intensive industry.

II. Fuel Field

Industrial Fuel Energy

- Wood charcoal, with excellent combustion characteristics, is a sustainable energy source for industrial production. It reduces reliance on traditional fuels and lowers carbon emissions.

- Specific application scenarios: Energy-consuming industries like power plants, boilers

BBQ Charcoal Processing

- High-quality wood charcoal, refined by charcoal briquette machine, is ideal for barbecues, offering excellent flavor for cooking and leisure activities.

- Specific application scenarios: Parties, picnics, etc.

Growing Field: Get Carbon Credit from Wood Biochar

01 Project Planning and Construction

- Feedstock: Use sustainable wood waste or forestry byproducts.

- Technology: Set up a wood charcoal making machine that operates under low-oxygen conditions to produce high-quality biochar.

- Key Goal: Maximize carbon stability — biochar should contain ≥50% stable carbon.

02 Project Operation and Assessment

To earn carbon credits, the project must demonstrate actual CO₂ removal and long-term storage. Use Life Cycle Assessment (LCA) tools or certified methodologies to calculate:

- Mass of feedstock processed

- Yield of biochar produced

- Carbon content of the biochar

- Stability/durability of carbon storage (typically >100 years)

- etc.

03 Become a CORCs Supplier

Register your project with an accredited carbon registry to receive CO₂ Removal Certificates (CORCs) and become a certified supplier. There are some recognized authoritative platforms.

| Platform | Notes |

|---|---|

| Puro.earth | The world’s leading crediting platform for engineered carbon removal |

| Carbon Standards International | Focus on climate, biochar, European Biochar Certificate (EBC), carbon removal, and World-Climate certification. |

| Carbonfuture | Offers robust tracking and MRV tools for transparent carbon accounting. |

| Isometric | The world’s leading carbon removal registry |

04 Carbon Credit Trading

Once your project is verified:

- Credits are issued and listed on the platform’s registry

- Sell credits to companies or investors aiming to offset emissions through durable carbon removal

- Typical price range: $100–$300+ per ton depending on project quality, certification, and demand

Benefit: Project owners and investors can generate sustainable returns through verified carbon credit sales.

Wood Raw Materials for Charcoal Production

Each year, approximately 15 million tons of wood waste are generated globally, yet less than 20% is effectively utilized. Common wood waste usually come from the following sources.

Raw Wood from Planting and Logging

Raw Wood from Planting and Logging

- Types: Wood trunk, branches, barks, etc.

- Source: typically from forest farms.

Wood Processing Scraps

Wood Processing Scraps

- Types: Wood chips, wood shavings, sawdust

- Source: sawmills, furniture manufacturers, etc

How Does Wood Charcoal Making Machine Work?

01 Prepare the Wood

To start, keep the wood in pieces sized 5-8mm and reduce its moisture content to below 15%. Beston Group provides crushers and dryers to help you meet these requirements efficiently.

02 Wood Pyrolysis Reaction

Automatic screw belt conveyor feed the prepared wood into the reactor, a sealed low-oxygen environment.

At temperatures between 380℃- 450℃, it causes the volatile substances in the wood to release while retaining the solid carbonaceous material, which forms charcoal.

03 Syngas Recovery and Flue Gas Dedusting

During the wood pyrolysis process, the generated flue gas contains rich combustible syngas. After purification, the syngas are reused as a heat source to power the main furnace. Waste flue gas after multiple dedusting will be safely emitted.

04 Wood Charcoal Collection

Superiority of Wood to Charcoal Machine

Efficient Production

- Double Heating Structure: The dual-layer cylinder body achieves double heating for waste wood. This ensures uniform and thorough heating of wood materials inside the reactor, thus increasing carbonization efficiency.

- Rigorous Insulation System: It effectively prevents wood from contacting smoke or hot gases, keeping it uncontaminated. This improves thermal efficiency.

- Low-Nitrogen Combustion: Enhances combustion efficiency by optimizing the combustion environment.

Safe Production

- Triple-Sealing and Enclosed Feeding System: Ensures the airtight integrity of the reactor and reduces the risk of reactor explosion.

- Automatic Ignition System: Reduces manual operation risks and enhances operational safety.

- Multiple Explosion-Proof Design: Provides critical safety protection by preventing large-scale explosions.

- Slight Negative Pressure Operation: Wood charcoal making machine operates in safe slight negative pressure. An explosion-proof vent is installed at the end of reactor to prevent excessive internal pressure.

Intelligent Production

- PLC (Programmable Logic Controller): It manages operations like feeding, carbonization, temperature control, and discharging to improve efficiency and reduce human error.

- IoT (Internet of Things): Enables remote monitoring and control through internet connectivity. Integrated sensors collect real-time data to maintain safe and efficient machine operation.

Eco-friendly Production

- Multi-Stage Dust Removal: Cyclone dust collectors are installed at key points including the dryer, feed port, and connecting pipes to effectively capture dust and maintain a clean worksite.

- Advanced Exhaust Treatment: Exhaust gases undergo dust removal, adsorption, and desulfurization to meet stringent EU emission standards.

Optional Configuration of Wood Coal Making Machine

Dryer

A dryer reduces the moisture content of wood waste before pyrolysis. Lower moisture improves thermal efficiency by reducing the energy needed for water evaporation. Thus, it enhances the pyrolysis reaction, lowers energy use, and shortens reaction time.

Crusher

A crusher breaks down larger wood feedstock into smaller, uniform particles before entering the reactor. This increases the surface area of the material, allowing for more efficient heat transfer and faster, more uniform pyrolysis.

Charcoal Briquette Machine

A charcoal briquette machine shapes powdered or granular charcoal into uniform briquettes, depending on requirements. This step is crucial for improving product density, ease of handling, combustion efficiency, and marketability.

Modern Wood Charcoal Machine Promotes Industrial Upgrading

Transformation of Traditional Charcoal Industry

The traditional charcoal industry has long relied on primitive earth kilns and manual temperature control. This way has low charcoal yield, high energy consumption, severe pollution, and low product added value. This extensive production model can no longer meet the current demands for green and sustainable industrial development.

By adopting modern wood charcoal making machine for efficient and large-scale production, the charcoal industry is transforming toward a high-efficiency, cleaner, and higher-value modern industrial model.

Development of Environmental Carbon Sink Industry

Modern wood charcoal manufacturing machine adopts a closed pyrolysis process, enabling wood biochar production. The biochar has a high carbon content and strong stability. When buried in soil, it can sequester carbon for hundreds to thousands of years. Each ton of biochar can offset approximately 2.5 to 3 tons of CO₂ equivalent. The Intergovernmental Panel on Climate Change (IPCC) recognizes it as a negative emissions technology.

Investing in modern wood to charcoal machine supports carbon removal efforts and advances the growth of the carbon sink industry.

Beston Group – Trusted Supplier of Wood Charcoal Making Machine

Leading Technical Strength

Beston Group’s senior engineers team is dedicated to developing wood pyrolysis to biochar technology. We actively participate in drafting national standards for pyrolysis processes. Our solutions and technologies consistently lead the industry.

Strict Quality Control

Beston Group upholds a strict quality control system. It includes raw material inspection, production testing, airtight safety checks, to delivery and installation inspections. The machine complies with ISO9001 and ISO14001 certification.

Top in the Chinese Pyrolysis Industry

Beston ranks among the top three exporters in China’s solid waste management sector. The wood charcoal manufacturing machines have been exported to over 30 countries and are widely used in international waste recycling and resource utilization projects.

Convenient One-stop Service

- Pre-sales: Technical consulting, solution customization, etc.

- On-sales: Equipment layout design, production report, etc.

- After-sales: Guidance on installation/operation/maintenance, ongoing technical support, and software system upgrades. etc.

Looking Forward to Cooperating with You

Ready to start your business with wood charcoal making machine? Partner with Beston Group for high-quality equipment, sustainable solutions, and exceptional support. Reach out to us today—let’s create a greener future together! More in Facebook/YouTube/Linkedin/Pinterest.