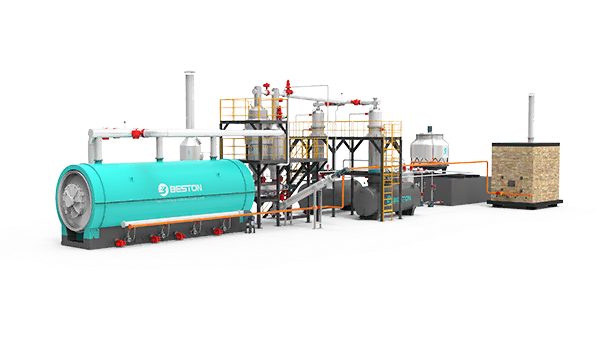

Oil sludge pyrolysis plant is a harmless solution for industrial oily waste treatment and soil remediation. It converts oil sludge into pyrolysis oil, sand, and combustible gas for reuse. Now the new-generation BLL-30 continuous oil sludge pyrolysis plant has launched on the market. It annually handle 12000 ton oil sludge, greatly contributing to environmental sustainability. Please learn more.

Parameters of Oil Sludge Pyrolysis Plant for Sale

BLL-30 Model Recommend

- Process 12,000 tons oil sludge annually

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get project approval

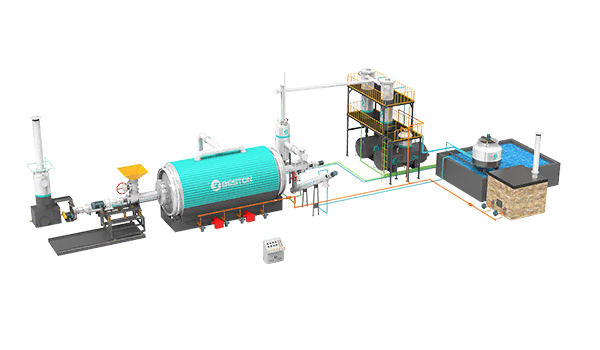

Batch Type: BLJ-20 Newly launched

- Process 7,500 tons oil sludge annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 6,500 tons oil sludge annually

- 1 batch/day

- 2 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 TDU | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge: 20-25t/d | 16-18t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+8*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 60 |

BLJ-20 Oil Sludge Pyrolysis Plant: Technical Breakthrough

Fractional Distillation Technology

- Naphtha with a boiling point below 200°C is directed to the light oil tank.

- Non-standard diesel above 200°C is sent to the heavy oil tank.

Large-capacity Pyrolysis Reactor (ø2800*10000)

The large-capacity pyrolysis reactor can process 20-25 tons of oil sludge per day.

Thermal Dynamic Sealing & Flexible High-temperature Insulation Technology

The integrated technology greatly enhances machine safety with better sealing, no oil-gas leaks, no open flames.

Technical Innovations of Beston BLL-30 Oil Sludge Pyrolysis Plant

Oil-Gas Anti-Polymerization Condensation Technology

Spray condensation system rapidly cools pyrolysis oil-gas. This prevents olefin polymerization that can clog oil-gas pipelines. Finally, BLL-30 can dispose 12,000 tons of oil sludge per year.

Hot Flue Gas Recycling + Air Preheating Technology

This technology recycles 80% of hot flue gas to mix with 1000-1300℃ hot air to heat the reactor. And it recycles the remaining 20% hot flue gas to heat fresh combustion air. This facilitates the project’s regulatory compliance.

Reactor Automatic Temperature Control Technology

The reactor of BLL-30 features a multi-fuel automatic combustion system and hot-air reuse system. This system automatically adjusts the mix ratio of different fuels in real-time. Thus, it achieves precise temperature control and stable oil output.

Compare Oil Sludge Treatment Solutions: Why Pyrolysis Stands Out?

Pyrolysis technology outperforms traditional oil sludge disposal methods in several key areas. It boasts high efficiency, low pollution, effective resource recovery, etc. This offers new possibilities for waste management and environmental protection. Below is a comparison of key oil sludge treatment technologies:

| Technology | Technological Features | Secondary Pollution | Process Maturity | Facility Investment | Energy Consumption | Application Scope |

|---|---|---|---|---|---|---|

| Thermochemical Washing | Incomplete oil recovery | A large amount of remaining polluted oil sludge | Simple and mature | Low | Medium | Suitable for simple oil recovery |

| Solvent Extraction | Relatively complete oil recovery | Solvent contamination | Complex, immature, with safety risks | High | Medium | Suitable for deep oil recovery |

| Biological Treatment | Long treatment cycle, poor treatment effect for cycloalkanes and aromatics | Secondary pollution risk | Complex, immature | Medium | Low | Suitable for final treatment of sludge with 3-5% oil content |

| Incineration | Able to treat all organic matter, but unable to recover original oil | Minimal ash, toxic and harmful gases | Complex | High | High | No scale limit |

| Pyrolysis | Able to treat all organic matter and effectively recover original oil | Minimal ash | Mature | Medium | Medium | No scale limit |

Common Pyrolysis or Catalytic Pyrolysis: Choose Your Technical Solution

Pyrolysis is a thermal decomposition process that occurs at high temperatures in the absence of oxygen. Beston Group offers 2 pyrolysis technology solutions (thermal desorption unit) for efficiently treating oil sludge with varying characteristics. Welcome contact us for a detailed consultation.

Common Pyrolysis

- Applicable Materials: oil sludge with a high oil content.

- Benefits: Achieve harmless disposal and volume reduction of oil sludge.

Catalytic Pyrolysis

- Applicable Materials: oil sludge with high wax content.

- Benefits: Prevent wax buildup in pipelines, reducing safety risks during production; facilitate the harmless disposal and reduction of waste.

Feedstock for Pyrolysis: Where Does Oil Sludge Come from?

The petroleum industry, vital to the global economy, also poses significant environmental challenges, particularly in oil sludge generation. This complex mixture contains harmful substances (heavy metals, PCBs, etc.), and some crude oil. Its improper handling can lead to severe soil and water pollution. Oil sludge is produced at various stages of petroleum economic activities, including:

Oil Exploration and Production

- Types: oil-based cuttings, operational sludge, and landed sludge.

- Formation: During the drilling process, waste like drilling mud, solid particles, drilling fluid residues and oil-bearing formation profile materials are mixed to form complex sludge.

Oilfield Gathering and Transportation

- Types: oil-based cuttings, tankbottom sludge.

- Formation: When oil is stored in tanks, heavy oil particles settle at the bottom, forming oil sludge. Common deposition locations include the bottoms of oil tanks, sedimentation ponds, sewage tanks, and grease traps.

Oil Refining

- Types: grease trap bottom mud, floatation pond scum and activated sludge.

- Formation: These wastes are byproducts of the treatment and separation processes during oil refining. These wastes often contain oil residues, chemicals, and other impurities.

Oil Spill Accident

- Formation: In the event of an oil spill, either from offshore rigs, pipelines, or storage facilities, large amounts of oil can mix with water, soil, and debris, forming a thick, oily sludge. This oil sludge can spread across vast areas and pose significant environmental hazards.

How Does Oil Sludge Pyrolysis Plant Achieve Harmless Treatment?

01 Feeding

Open reactor door and connect hydraulic feeder to it. Under the pressure of hydraulic feeder, oil sludge goes to reactor. Remove hydraulic feeder after feeding and close and lock the door tightly.

Note: Choose the appropriate feeder according to the state of the oil sludge.

| Oil Sludge Moisture Content | Recommended Feeding Method |

|---|---|

| Below 40% | Belt Conveyor |

| 40%-60% | Shaftless Screw Conveyor |

| Above 75% | Oil Sludge Pump |

02 Preheating and Pyrolysis

03 Oil Gas Condensation and Pyrolysis Gas Recycling

04 Flue Gas Dedusting

05 Water-cooling Discharging

Final Products of Oil Sludge Pyrolysis Plant

Pyrolysis Oil

Pyrolysis oil is primarily made up of hydrocarbons. These compounds are derived from the breakdown of the organic materials in the oil sludge, including oils, greases, and hydrocarbons. It can be used in such ways:

- directly sold and used as industrial fuel;

- as raw oil for reprocessing into non-standard diesel;

- further refined for chemical feedstock.

Naphtha & Non-standard Diesel

The two are obtained from BLJ-20 oil sludge pyrolysis machine.

Naphtha is commonly used as a blending component in gasoline, a feedstock for petrochemical production (such as for the cracking of ethylene and propylene), as well as a solvent and cleaning agent.

Non-standard diesel is mainly used in applications with lower fuel quality requirements, such as construction machinery, ships, boilers, or power generation equipment.

Sand

Sand is a by-product formed from the minerals and impurities in the oil sludge during pyrolysis. It can be applied in such way:

- used in landfills, sold to brick factories for brick production;

- sold to oil companies as an anti-collapse agent for oil wells.

Combustible Gas

The combustible gas produced includes methane (CH₄), carbon monoxide (CO), hydrogen (H₂), and other light hydrocarbons. These gases come from the decomposition of organic substances like oils and fats in the oil sludge, which break down into smaller molecules under high temperatures.

- Usually directly purified and reused to provide heat to the oil sludge pyrolysis plant.

Possible Profit Sources from Oil Sludge Pyrolysis Plant

Selling Pyrolysis Products

- Potential Buyers: Oil refineries, construction companies, etc.

- Profit Income: Dependent on the market price of pyrolysis products.

- Reason: Pyrolysis products have wide industrial applications. The potential buyers are willing to purchase these cost-effective industrial materials.

Government Economic Subsidies

- Potential Source: Policy subsidies and tax incentives

- Profit Income: Subsidy amounts vary by specific region and policy.

- Reason: Governments around the world encourage businesses to prioritize waste management through financial subsidies. Oil sludge pyrolysis become one focus due to its environmental benefits.

Charging for Hazardous Waste Disposal

Potential Target: Entities generating oil sludge waste, such as oil drilling companies and chemical plants.

Profit Income: Disposal fees depend on waste volume, type, and local environmental regulations. For example, a waste management company in Nigeria charges $200 per ton for processing oil sludge with pyrolysis technology. In the long term, this can fully cover the oil sludge pyrolysis plant cost.

Reason: Oil sludge is classified as hazardous waste, and many countries have strict regulations regarding its disposal. Companies can charge waste-generating entities for the disposal process. As environmental regulations become more stringent, the demand for hazardous waste disposal services is increasing, particularly from industries like oil and chemicals that generate large quantities of waste.

Embrace Superiority Designs of Beston Oil Sludge Pyrolysis Plant

Nitrogen Replacement Technology – Safty Assurance

- Prevents flash explosions within the reactor of oil sludge pyrolysis machine.

- Ensures both equipment safety and operator security.

Hot Air Heating Technology – Energy Saving

- Avoid materials contact with air, effectively reducing harmful gases like dioxins.

- Achieve more uniform heating and more precise temperature control.

Floating Seal Technology – Safty Production

- Achieve reactor’s dynamic sealing with carbon fiber and high-temperature soft filler.

- Offer exceptional resistance to high temperatures, corrosion, and wear.

Anti-coking Technology – Smooth Operation

- Effectively minimizes coking and residue build-up, ensuring smooth and efficient operations.

- Reduce the maintenance frequency and maintenance costs of the oil sludge pyrolysis equipment.

EU-standard Dedusting Technology – Green Production

- Ensure all emitted gas won’t harm the atmosphere.

- Support environmental regulations and promote sustainable development.

PLC and IOT Technology – User-Friendly Interface

- Achieve real-time monitoring and alarm, automatic data collection, and wireless remote transmission.

- Enhancing operational convenience and safety.

Global Cases of Oil Sludge Pyrolysis Plant

Installation Site of Oil Sludge Pyrolysis Plant in Oman

Project Time: from 2024;

Configuration: 1 set of BLJ-16 with 12-16 ton/day capacity;

Installation Method: Engineer on-site guidance.

Installation of Oil Sludge Pyrolysis Plant in China

Project Time: from 2023;

Configuration: 4 sets of BLJ-16 small pyrolysis machine;

Project Goal: Coordinated operation of multiple oil sludge pyrolysis plants to meet larger-scale demands.

Install Oil Sludge Pyrolysis Treatment Plant in Africa

Project Time: from 2023;

Configuration: 1 set of BLJ-16 with 12-16 ton/day capacity.

Partner with Beston Group in Oil Sludge Disposal Sector

Partnering with Beston Group, you’re teaming up with an industry leader in oil sludge disposal. Beston Group offers pyrolysis solutions that efficiently reduce oil sludge volume while achieving harmless disposal. Advanced oil sludge pyrolysis plant will maximize environmental sustainability. Let Beston Group help you achieve sustainability goals. More updates on Linkedin.