Plastic pyrolysis process is an advanced chemical recycling process that breaks down plastic polymers at high temperatures under oxygen-free conditions, converting waste plastics into valuable pyrolysis oil and gases. This technology not only helps reduce reliance on landfilling and incineration but also provides alternative feedstocks for the energy and chemical industries. In this article, Beston Group will take you on an in-depth look at the core principles and practical value of plastic pyrolysis.

Technical Principles of Plastic Pyrolysis Process

Regular Technology: Plastic Pyrolysis

- Principle: Waste plastics are thermally decomposed at high temperatures under oxygen-deficient or oxygen-free conditions. The basic mechanism involves using heat to break the polymer chains of plastics, cracking large molecules into smaller ones and producing liquid oil, combustible gases, and a small amount of solid residue.

- Product Features: Pyrolysis oil containing wax.

- Current Application: Conventional pyrolysis is the most fundamental and widely applied process.

Extended Technology: Catalytic Plastic Pyrolysis

- Principle: Building upon conventional pyrolysis, catalysts—such as zeolites—are introduced to improve reaction efficiency and product quality.

- Product Features: High-quality pyrolysis oil.

- Industrial Outlook: With continuous advancements in catalytic materials and process optimization, catalytic pyrolysis is increasingly becoming a key direction for the large-scale commercialization of plastic pyrolysis.

- Advantages: Higher liquid oil yield with significantly improved oil quality. Lower energy consumption, enhancing economic feasibility. Reduced equipment clogging and minimized downtime losses.

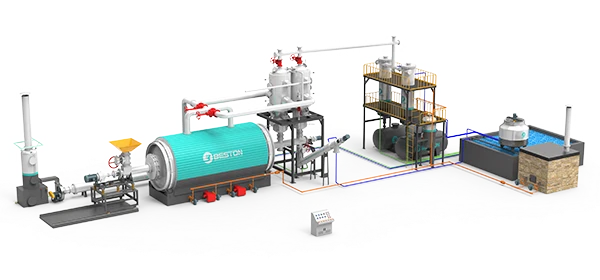

Involved Equipment in Plastic Pyrolysis Process

To carry out plastic pyrolysis, a special machine called a plastic pyrolysis plant is used. It is built to withstand high temperatures and keep the process free of oxygen. This creates the right conditions for plastic waste to break down safely and turn into useful products.

Continuous Type: BLL-30

- Large-scale choice: process 6,000 tons annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and project approval

Batch Type: BLJ-16

- Small-scale choice: process 3,000 tons annually

- 1 furnace/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

Plastic Pyrolysis Process Steps: Catalytic Pyrolysis Technology

01 Feeding

Feed plastic waste into plastic pyrolysis reactor. In the video, the batch plastic to oil machine adopts a hydraulic feeder. Remove the hydraulic feeder after feeding. The door must be closed and locked.

02 Preheating

03 Catalytic Pyrolysis

04 Condensing and Pyrolysis Gas Treatment

05 Discharging

06 Flue Gas Dedusting

What Plastic Types Suit Plastic Pyrolysis Process?

The success of the plastic waste pyrolysis process relies heavily on selecting the right types of waste plastics as raw materials. Different plastics have unique chemical compositions, influencing pyrolysis efficiency, safety, and output.

Recommend PE, PP, PS, and more

These plastics are highly recommended for pyrolysis due to their high oil yield during decomposition.

Refuse Chlorinated Plastic (PET)

Its pyrolysis releases hydrogen chloride gas which corrodes equipment. The produced pyrolysis oil may emit carcinogenic dioxins when combusted.

Refuse Oxygenated Plastic (PVC)

Its pyrolysis does not yield oil and Releases oxygen which poses a safety hazard.

What Is the Output of Plastic Pyrolysis Process?

The pyrolysis process for plastics focuses on producing liquid pyrolysis oil, which can be used as an alternative to traditional fossil fuels or further refined to diesel or gasoline. Oil yield for reference:

What Factors Affect Plastic Pyrolysis Process?

Several factors significantly influence the efficiency and output of the plastic pyrolysis process. Optimizing these factors helps maximize the yield of expected end products and minimize environmental impact. Key considerations include the following:

Pyrolysis Temperature

- Meaning: the heat level inside the reactor during pyrolysis, typically measured at °C.

- Influence: It significantly influences pyrolysis efficiency and end product type. Higher temperatures accelerate reactions, but excessively high temperatures can cause unwanted side reactions and energy inefficiencies.

- Example: To get a high oil yield, recommend 300-400℃. To maximize syngas yield, recommend 500-1300℃.

Heating Rate

- Meaning: the speed at which the temperature increases during the plastic pyrolysis process, typically expressed at °C/min.

- Influence: A high heating rate typically results in a higher yield of combustible gas and less solid residue. A slower heating rate may bring more liquid fuel oil and solids.

Reactor Pressure

- Meaning: the force exerted by gases or vapors on a unit area within a reactor, typically expressed in pascals (Pa) or atmospheres (atm).

- Influence: Pressure inside the reactor also affects the composition of the products. Maintaining proper intracranial pressure is also a means to ensure the safety of plastic pyrolysis process steps.

- Example: Beston Group’s pyrolysis plant maintains a micronegative pressure in the reactor to ensure safety.

Residence time

- Meaning: the average amount of time that reactants spend in a reactor, typically measured in seconds (s) or minutes (min).

- Influence: Balancing residence time is important – too short may result in incomplete conversion, while too long may lead to the formation of undesirable by-products. A shorter residence time typically produces more liquid products. A longer residence time leads to more gas formation.

Reactor Design

- Meaning: the different kinds of equipment or vessels used for conducting pyrolysis reactions. Common types include fixed-bed reactor, fluidized-bed reactor, rotary kiln reactor, and more.

- Influence: Different types of reactors have varying mixing and heat transfer characteristics, which can impact the efficiency of the pyrolysis process and the distribution of products.

- Example: Beston Group utilizes rotary kiln reactor design, which offers uniform reaction and high thermal efficiency.

Catalysts

- Meaning: a substance that accelerates a decomposition reaction, usually not consumed in the process, remaining unchanged after the reaction.

- Influence: An appropriate catalyst can increase the yield of desired products and reduce the overall energy input of the process. The proportion of the same catalyst (the ratio of catalyst to plastic) can also have different effects on pyrolysis.

- Example: The ZSM-5 catalyst can reduce impurities like solid residues, sulfur, nitrogen, and phosphorus in the liquid oil produced. For example, when the ratio of kaolin to WPP plastic is 1:2, the oil yield reaches its highest at 80.75 wt%.

Pyrolysis Paves the Way for Plastic Sustainability

The plastic pyrolysis process represents more than just a technological pathway—it embodies a vision for a circular economy where waste is not the end but the beginning of new resources. It bridges today’s environmental challenges with tomorrow’s sustainable industries. As research deepens and applications expand, pyrolysis may well become a cornerstone of how societies rethink waste and reshape the future of materials. For professional guidance, please consult Beston Group.