Pyrolysis plant in the Philippines supports the country’s national renewable energy plan by converting waste resources (plastics, tires, rubber, and oil sludge) into valuable pyrolysis fuel oil. These plants help with waste management and renewable energy goals. Welcome to know about pyrolysis in the Philippines with Beston Group.

What Is Pyrolysis Technology in the Philippines?

A pyrolysis machine in the Philippines decomposes organic materials such as waste plastics and rubber by heating them in an oxygen-free environment, producing fuel oil, combustible gas, carbon black, and other by-products. Key elements of the technology include:

Materials are typically heated between 350°C and 900°C. In the Beston pyrolysis plant in the Philippines, the reaction temperature generally ranges from 200°C to 400°C. The temperature setting affects the quality and quantity of the end pyrolysis products. For example, lower temperatures tend to produce liquid fuels, while higher temperatures may result in more gas products.

An oxygen-free environment prevents the complete combustion of organic materials. This is achieved by minimizing air inflow, preventing oxygen from participating in the reaction. Pyrolysis equipment may use nitrogen displacement technology or advanced reactor sealing to ensure this. As a result, materials decompose into valuable liquid oil, solid carbon black, and combustible gases, rather than fully burning into carbon dioxide and water.

Beston pyrolysis technology is suitable for:

- Waste Plastic: PE, PP, PS, etc., can be converted into fuel oil and carbon black.

- Waste Rubber: various tires and rubber products can be turned into fuel oil, carbon black, and steel wire.

- Oil Sludge: Drilling cuttings, oil tank sludge, refinery sludge, etc. can be recovered as valuable oil.

Working Principle of Pyrolysis Plant in the Philippines: Video Guide

Is There A Pyrolysis Plant in the Philippines?

Yes. The Filipino investor has seen a growing interest in pyrolysis technology. Several pyrolysis plants in the Philippines are currently in operation. These facilities are primarily situated in industrial zones. Maybe you can consult local government offices or industry associations to learn more about specific plant locations and operational details. At present, Beston Group has collaborated on several pyrolysis projects in the Philippines:

Which Industries in the Philippines Drive the Demand for Pyrolysis Plants?

Different industries might choose sustainable and economically viable pyrolysis solutions to reduce pollution, recover resources, and lower production costs. For example:

Rubber Industry

The Philippine government has recently ramped up its support for the rubber industry, highlighted by a June 2024 agreement with the Philippine Rubber Research Institute (PRRI) to bolster the sector. As the rubber industry expands, it will generate large amounts of waste rubber products and scraps. Pyrolysis offers an effective solution.

Plastic Recycling Industry

The Philippines consumes nearly 480,000 shopping bags daily, amounting to approximately 1.75 billion bags annually. The prevalence of budget-friendly small plastic packaging goods brings local area severe marine plastic pollution. Plastic pyrolysis machine solves this problem by converting waste plastic into valuable products.

Energy Industry

With the rapid urbanization in the Philippines, the energy demand is on the rise. Pyrolysis, which converts organic waste into energy-rich fuel oil, offers a way to address the growing energy needs while promoting environmental sustainability. Filipino investors in the energy sector are increasingly interested in this innovative solution.

Chemical and Manufacturing Industries

The chemical and manufacturing industries often require materials like petroleum-based products and carbon black for production. Pyrolysis technology can extract these essential products from organic waste. This approach not only helps reduce production costs but also enhances industry competitiveness.

Economic Benefits of Pyrolysis Products for Filipino Customers

Pyrolysis Oil

Pyrolysis oil usually serves as industrial alternative fuels or as a raw material for refining or chemical processing. Its sale offers the main revenue stream. Investors can profit from it.

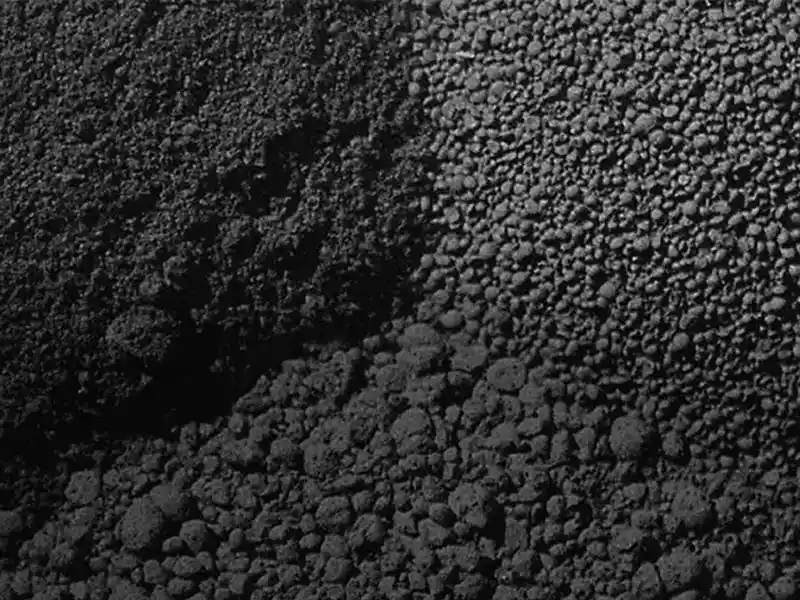

Carbon Black

It is used as a reinforcing agent in rubber products, particularly in tire production, and as a pigment in plastics, inks, and coatings. Selling them can bring some income for investors.

Steel Wire

Steel wire can be reused in tire production or reprocessed into other metal products. Investors can sell them to steel mills or recycling companies.

Combustible Gas

The combustible gas generated during the pyrolysis process can be utilized to fuel the pyrolysis plant itself, significantly reducing operational costs.

Parameters of Pyrolysis Plant in the Philippines for Sale

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

Technology Advantages of Beston Pyrolysis Plant in the Philippines

Beston’s continuous pyrolysis plant has a 30-35t/d capacity. It can achieve uninterrupted operation without cooling, maximizing productivity.

To tackle the issue of wax oil clogging pipelines in plastic pyrolysis, we independently develop a catalytic wax removal technology solution.

In the event of overpressure in the pyrolysis reactor, the safety valve will be automatically opened for emergency pressure relief to ensure equipment safety and personal safety.

The optional high-end exhaust gas treatment system offers semi-dry or fully dry desulfurization, denitrification, and de-dusting to meet European emission standards.

What Registered Qualifications May Need Before Starting Pyrolysis in the Philippines?

In the Philippines, it is permitted to set up tire/plastic pyrolysis plant and thermal desorption unit that meet local environmental standards. Businesses need to acquire environmental, building, and business permits. Specific requirements can vary by region. Some common permits include:

Launch Your Pyrolysis Business in the Philippines

Collaborate with Beston Group to establish a pyrolysis plant in the Philippines today! Beston Group offers end-to-end support, from project planning and plant design to installation, training, and after-sales service. Our advanced technology and customized solutions ensure that your pyrolysis plant operates efficiently, maximizing your return on investment while minimizing environmental impact. Follow us on YouTube, Linkedin, Facebook, and Pinterest for every update!